PTFE is a unique material with fluorine and carbon atoms. Usually, the material is hydrophobic, non-sticky, non-reactive, has a high density, and is resistant to high temperatures.

This makes it a perfect choice for many applications

PTFE Mechanical Properties

Tensile and Compressive Properties.

It ranges from as low as 10Mpa all the way to 35-40Mpa. This depends on the used filler, the molding parameters, and also the quality of the base resin.

Flexibility

Flexural modulus differs according to different temperature environments as shown below.

| Temperature | Flexural Modulus |

| (20-22)0C. | (350-650)N/mm2 |

| -800C. | 2000N/mm2 |

| 1000C. | 200N/mm2 |

| 2600C. | 45N/mm2 |

Hardness of PTFE

| Measurement Method | Value |

| ASTMD 2240 | D50- D60. |

| DIN 5345 | (27-32) N/mm2 |

Coefficient of Friction

A low coefficient of friction ranging from 0.05 to 0.09. It is usually constant at room temperature.

However friction coefficient changes according to the following factors:

- Increasing the load of an object that slides on the surface of the PTFE will decrease the friction coefficient.

- Increases with an increase in speed of the gliding object.

Wear Properties

This depends on the surface of materials sliding with the PTFE and also depends on the speed of sliding and loads of materials. Usually, it makes the PTFE very poor wear resistance, hence making it only suitable for lighter loads but not for heavy loads.

Physical Properties

Key physical properties include:

- 03% max water absorption

- 36 to 0.91 g/cc apparent bulk density

- 01 to 0.058 linear shrinkage

PTFE Thermal Properties

Thermal Stability

PTFE is thermally stable.

Decomposition of it by heat starts occurring at temperatures of over 4000C.

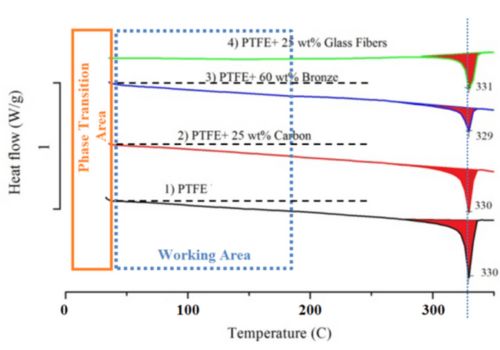

Transition Points

The molecular structure of PTFE changes according to temperature change. At 190C and 300C crystal transformation takes place. Whereas at the temperature 3270C, there is fading of crystalline structure.

Thermal Expansion

This varies with different temperatures and also relatively changes according to changes in direction.

Thermal Conductivity

Thermal conductivity is low making PTFE a good insulating material. This can be increased by adding fillers.

Specific Heat

The amount of heat content increases with regard to the temperature. When the temperature is high it results in to heat content of PTFE material being high.

Electrical Properties of PTFE

Dielectric strength

PTFE thickness is directly proportional to material thickness. Similarly, it also decreases with an increase in frequency.

Dielectric Constant and Dissipation Factor

Has a very low dissipation factor of 0.0001 to 0.0003. This remains constant up to temperatures of 3000c and a frequency of 109 Hz. PTFE has a dielectric constant of 2.1.

Arc Resistance

Arc resistance is the ability of an insulator to withstand high voltage without forming a conducting path along its surface. PTFE has good resistance of 300 sec.

Corona Effect

Corona effect is the ionizing of the surrounding air of a conductor which forms a glow and hissing sound. The Corona effect causes some erosions on the PTFE surface.

Optical Properties of PTFE

Resistance of Light

According to some test samples that have been exposed to more than 20 years of sunlight shows no change. Hence proving that PTFE is resistant to decomposition by sunlight

Resistance to Radiation

It has a poor resistance to radiation. This is due to its decomposition when exposed to high-intensity radiation.

Other PTFE Material Properties

Plastic “Memory”

When PTFE materials are deformed, they can retain their original form after being heated. PTFE has good plastic memory.

Gas Permeability of PTFE

This is the ability of gas to diffuse through a material when pressure between both sides is different. PTFE gas permeability depends on thickness, the pressure between both sides and the working techniques of the PTFE material.

Resistant to Corrosion by Chemical

PTFE is not affected by most of the known compounds and elements. It is affected by:

- Alkaline metals in the elementary state

- Chlorine trifluoride

Solvent Resistance

It cannot dissolve in most solvents except for high fluorinated oils at a temperatures ver 3000C

How Additives & Fillers Affect PTFE Material Properties

Glass Fiber

Reduces the rate of creep which is the deformation when subjected to pressure and time. Glass fiber also makes PTFE resistant to wear, chemically resistant, and makes it suitable for higher surface pressure. Used in making rings, bushings, threaded connections, etc.

Adding of Carbon

Carbon should be used in either powder form or as fiber. It reduces the rate of creep, results in an increase in thermal conductivity, and improves compressive strength.

Additionally, it makes PTFE more resistant to wear and electrically conductive.

Carbon Combined with Graphite

Reduces PTFE wear due to low friction coefficient. Ideally, it provides “perfect” lubrication.

Bronze-filled PTFE Compound

- Results in an increase in thermal conductivity

- Improves electrical conductivity

- Makes it more pressure resistant

- It improves creep resistance properties

It has a high friction resistance which can be reduced by the addition of MoS2.

Some disadvantages include possible oxidization. This is alongside poor chemical resistance.

Molybdenum (MoS2)

Molybdenum has a lubricant effect making the material have anti-friction properties.

Calcium Fluoride (CaF2)

Used as an alternative for glass fiber if the glass is not suitable due to chemical resistance. It is used in the making of gaskets, making of electronic applications.

Mica

Mica guarantees that the PTFE expands and shrinks less. Nevertheless, Mica has limited mechanical properties. This is mostly applicable in compression techniques.

Ekonol

Ekonol makes PTFE work better at higher temperatures, and also makes it wear-resistant and makes it wear-resistant to steel counter material. This makes PTFE applicable for rotary, food applications, and applications with soft counter materials.

Wollastonite

Wollastonite has similar properties as glass fiber but is food applicable and also less abrasive.

Conclusion

As you can see, the superior properties make PTFE a perfect choice for many applications. The best part, you can also modify PTFE to get superior properties for any application requirements.

For all your PTFE rods, PTFE sheets, or virgin PTFE, contact us now.

More Resources:

Polytetrafluoroethylene – Source: Science Direct

PTFE Applications – Source: Hansa

PTFE – Source: Wikipedia

PTFE Manufacturing Process – Source: Hansa