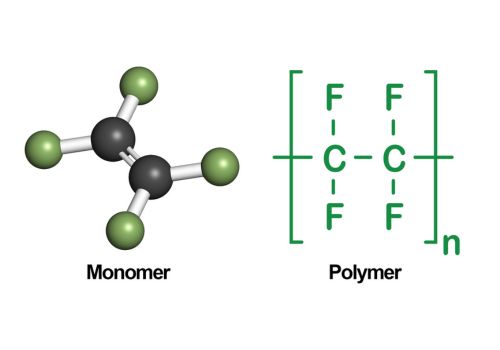

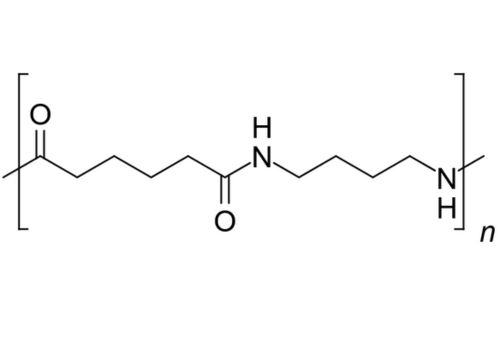

Whereas Nylon is a synthetic fiber made from coal, water, and air. On the other hand, Teflon is a synthetic fluorocarbon polymer and hence contains both carbon and fluorine.

This guide will major its emphasis on the comparison between these two components in various aspects.

Elements in Teflon compared to Nylon

In Teflon, this polymer consists of fluorine and carbon elements while in Nylon, it has oxygen, carbon, hydrogen, and nitrogen elements.

PTFE vs Nylon: Mechanical Properties

The mechanical properties of these two components are as discussed below;

While nylon’s maximal tensile strength is 12,400 psi, PTFE’s is between 1450 and 6240 psi.

Teflon’s tensile modulus ranges from 58 to 261 psi, while nylon’s is 470,000 psi.

Teflon has a flexural modulus of between 72.5 and 102 ksi, while nylon has a modulus of 410,000 psi.

Whereas nylon’s compressive yield strength ranges from 6 to 162 MPa, PTFE’s ranges from 10.5 to 27.6 MPa.

PTFE has a 3 ft-lb/in izod impact while nylon has a 1.2 ft-lbs/in izod impact.

Whereas nylon’s Rockwell hardness R goes from 100 to 120, PTFE’s is between 50 and 55.

Teflon has an elongation at break of 6.6 to 300 % while nylon has an elongation at break of 5.0 to 120 %.

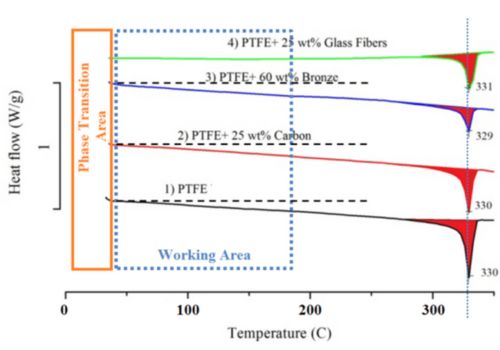

Teflon vs Nylon Temperature

Under temperature, we have the following comparisons;

Teflon’s coefficient of thermal expansion is 151 x 10-6 per° C while nylon ranges from 90 to 95.

Comparing their melting points, Teflon has a melting point of 327 0C while nylon has a melting point of 268 0C.

Whereas Teflon can withstand temperatures as low as -328 °F and as high as 500 °F, nylon can withstand temperatures between 40 and 185 °F.

Nylon vs PTFE Price

The prices of Teflon are more expensive when compared to the prices of nylon.

Teflon’s higher melting point, which demands higher energies than nylon’s easily attainable melting temperature, is the reason for the price disparity.

Nylon vs Teflon Coefficient of Friction

Teflon has a coefficient of friction ranging from 0.05 to 0.20 compared to 0.37 for nylon.

This is because nylon has better flexural and tensile strength and superior wear resistance, but Teflon is chemically inert and non-polar, making it difficult for materials to stick to it.

Other differences include

Water Attraction

Teflon is non-polar and has a low water affinity, which causes it to repel water, as opposed to nylon’s propensity to attract water. Teflon becomes hydrophobic in this situation, but nylon becomes hydrophilic due to its propensity to draw water.

Chemical Reactivity

Teflon’s weak carbon and fluorine bonds prevent it from being reactive, but nylon’s resins are stable and make it reactive.

Conclusion

Nylon is inferior to Teflon as a material. Teflon can be used in settings with high moisture levels due to their hydrophobic nature hence their ability to repel water. Therefore, we conclude PTFE is best to use compared to nylon.

More Resources:

How is Nylon Made – Source: OpenLearn

PTFE Manufacturing – Source: Hansa