Graphite Packing

Graphite packing is made from graphite filament which has been twisted together. The end products are yarns that require further braiding to produce high-quality and tough graphite packing material.

Usually, the braided graphite packing is durable with high tensile strength.

Depending on the specific applications, the braided graphite packing can be treated with special chemicals. For instance, you can coat braided graphite packing with PTFE before adding agents to further improve sealing capability.

Features of Graphite Compression Packing

There are many reasons why graphite packing is common in most modern applications and these include:

- High chemical resistance – it can withstand most acids and alkalis

- Self-lubricating feature – hence zero friction in most applications

- Graphite packing has a wide temperature range hence suitable for high-temperature and cryogenic applications

- Dimensionally stable packing solution

Graphite Packing Applications

Graphite packing is suitable for both static and moving applications. Some common applications include:

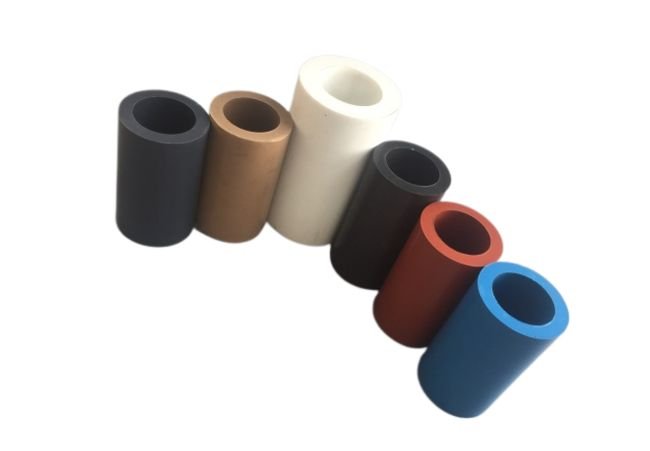

Graphite packing rings – some common applications include graphite packing for valves, faucets, etc.

Graphite packing seal – best for mechanical parts and requires watertight sealing

Graphite packing string –common in stuffing boxes, shafts, etc.