Carbon Filled PTFE

If you are looking for polytetrafluoroethylene with improved thermal conductivity, then PTFE with carbon filler is a perfect option. The carbon fillers are responsible for the PTFE material’s static dissipative property.

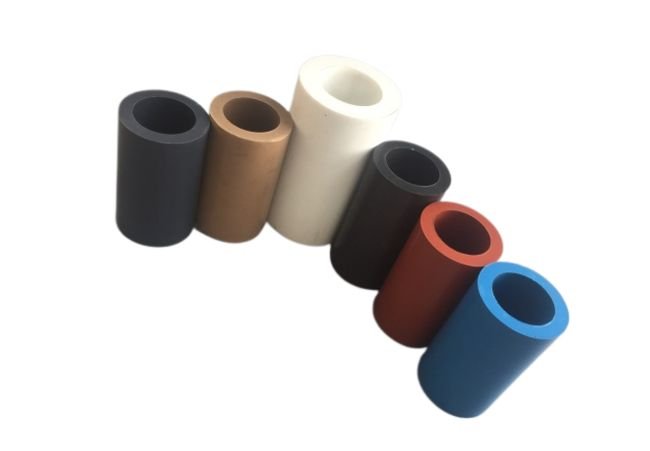

Like other polytetrafluoroethylene materials, you can find many forms such as carbon-filled PTFE rods, carbon-filled PTFE sheets, carbon-filled PTFE tubes, etc.

Like other fillers, carbon-filled PTFE exhibit improved performance characteristics such as:

- Improved resistance to deformation even under heavy load

- Exhibits improved compressive strength

- Better resistance to wear

- It exhibits low permeability

- Improved thermal conductivity due to carbon fillers

- Better extrusion resistance

Your Professional Carbon-Filled PTFE Manufacturer

Compared to glass-filled polytetrafluoroethylene, carbon-filled PTFE is less abrasive. Again, it is worth noting that carbon-filled PTFE performs better in strong bases and HF, with a low coefficient of friction.

At the same time, carbon fillers lower PTFE creep properties. However, the carbon-filled PTFE temperature range is -200°C o +260°C.

In most cases, carbon fillers in PTFE can range from 0.2% to 40%. The amount of carbon fillers by weight (%) will depend on the specific performance properties you want to achieve.

Applications of Carbon-Filled PTFE

Seals and rings – suitable for high-pressure and dynamic applications

Anti-static applications – this is due to low permeability and improved thermal conductivity

Carbon-filled PTFE brushing – due to its hardness and wear resistance

At times, you may add other fillers to carbon-filled Teflon for enhanced performance. Some common PTFE fillers are 3% graphite and 10% glass.

- Performance Table

- Specification Sheet

| PROPERTY: | (MEASURING METHOD:ASTM D4894) | |||

| 15% carbon +85% PTFE | 25% carbon +75% PTFE | unit | ||

| SPECIFIC GRAVITY: | 2.12±0.02 | 2.08±0.02 | g/cm3 | |

| TENSILE STRENGTH: | 19±3 | 18±3 | Mpa | |

| ELONGATION: | 250±50 | 150±50 | % | |

| BULK DENSITY: | —— | —— | g/l | |

| HARDNESS: | 60 | 60 | shore D | |

| FLOW-ABILITY: | —— | —— | sec/50g | |

| AVE.PARTICLE SIZE: | —— | —— | micron | |

| SHRINKAGE: | 2.0-3.0 | 1.6-2.6 | % | |

| PRESSURE | 400 | 400 | kg/cm2 | |

| MAX SINTERING TEM. | 380 | 380 | ℃ | |

| Molded sheet | 1200*1200mm | Thickness:5–100mm | |

| carbon filled Tube | OD30MM—2000MM | ID10MM–1650MM | Length:50–300mm |

| carbon filled rod | OD30MM–3000MM | Length :50–300mm |