PTFE (polytetrafluoroethylene) also called Teflon comes with numerous properties. This has made them useful and beneficial in many industries or sectors.

Utilizing PTFE in Different Industries

Some industries which have benefited from PTFE include:

1. Construction Industry

The use of Teflon is common in the construction industry. Some of the reasons they are used in this industry include:

- Due to its ability function perfectly as electrical insulators.

- Their unique ability to resist abrasion and corrosion.

Some of its applications for your construction business:

- PTFE is used to cover and secure electrical wires. This is because of its resistance to high temperature, chemicals, and water – properties.

- Teflon coatings helps to make construction equipment and tools stronger.

- Gas line hoses and pipes can be made using Teflon.

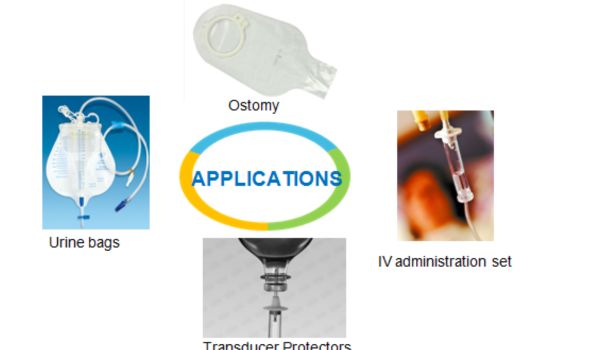

2. Medical Industry

In the medical industry, the medical-grade properties that Teflon comes with including its high resistance to high chemicals and friction make it famous.

Some applications in this industry include:

- In making medical tools or devices such as heart patches, cardiovascular grafts, and ligament replacements.

- Teflon is used to make catheters, forceps, sutures, and other medical and test equipment.

More reasons it is used in this industry

- Since PTFE complies with the regulations of the FDA and standards of care, it is really welcomed by the medical industry.

- PTFE when expanded is highly inert and adaptable biologically. Due to that, the body doesn’t reject it. Also, it has no negative physiological effects on the body.

- When expanded, PTFE can be sterilized using any process.

3. Food and Beverages Industry

Teflon coatings are present on non-stick pots and pans. PFTE’s heat-resisting, and non-sticking features make this possible. PTFE is also used in making kitchen and cooking gadgets or appliances such as coffee makers, microwaves, blenders, waffle irons, etc. This means, with non-stick pans, food doesn’t stick into pans anymore.

More reasons it is used in this industry:

- It is a good insulation for electricity. So, it is perfect for electrical insulation which makes it ideal for making pipe liners.

- PTFE is perfect for seals and coatings as well.

- Its level of durability is very high, and it can withstand consistent utilization at very high temperatures.

- The benefit of Teflon to this industry also includes its food-safe grades as well as non-stick properties.

- PTFE coatings easily adhere to different surfaces like soda-lime glass, aluminum, and borosilicate.

- Saving money in this industry is easier with PTFE coated kitchen equipment and utensils. This is because they help these devices and utensils last for a long.

- Teflon coated kitchen utensils and appliances are very easy to clean and maintain.

4. Chemical Manufacturing and Processing Industry

Reasons you must consider Teflon in this industry:

- The smoothness that comes with moving harmful or corrosive chemicals when PTFE is involved is one reason for its use in this industry. This is due to its anti-corrosion-resisting property.

- It can withstand very harsh environments which work for these chemical manufacturing and processing methods, even as it adds some level of safety.

- Using Teflon continuously to move chemicals will not lead to them melting or eroding no matter the temperature and pressure.

- The non-friction nature of PTFE makes it easy for highly viscous chemicals or liquids to freely flow.

Here are some of its applications you must know:

- Used for heat exchanger coating.

- Ideal for pumps

- Perfect for tanks and reaction vessels.

- PTFE is perfect for pipes (transport, exhaust, and steam) for corrosive gases.

- Autoclaves, containers, and impellers.

- High-pressure oil pipes, rolling mills, and valves.

- Cold pressure systems and diaphragms.

- High- and low-pressure pipes are ideal for aircraft hydraulic systems, etc.

They can be found being used as well in refrigeration systems.

5. Aerospace and Automotive Industry

Why do you need it if you are in this industry?

- Teflon’s high resisting and thermal stabilizing properties make it ideal for use in engine parts and car exteriors.

- The leak-proof benefits PTFE comes with, not forgetting its high-reliability levels in different temperature setups, is why it is needed in this industry.

- You can trust that Teflon will prevent the deterioration of your automobile or any machine.

- Fuels and lubricants have corrosive chemicals in them. PTFE is able to resist all these chemicals perfectly.

- PTFE resists flames which mean brings in safety when used.

- It has unique water-resisting properties and can repel water.

- There are no way carbon particles can be deposited if PTFEs are used in making parts.

List of some applications:

- O-rings

- Valve steam and shaft seals

- Gaskets

- Lining of fuel hose

- Gears

- Power steering and transmission

- Wiper blades

- Glass windshield,

- Use in air brake systems, etc.

6. Electrical and Electronic Industry

- Used due to their high-quality insulation features, especially when under highly harsh conditions.

- Teflon is used to ensure corrosive materials, chemicals that corrode, and high temperatures, are withstood. It withstands them all without losing the design flexibility required.

- Copper, which is a filler can be included or added to Teflon to enhance the level of conductivity. This works for thermal and electrical purposes.

- It has high dielectric features making it perfect for frequency control.

Unique PTFE applications you should know of:

- Manufacturing of insulations.

- Manufacturing semiconductor components or parts.

- Ideal for making flexible printed circuit boards.

- Decorated wires for micro motors, control devices, and thermocouples.

- Capacitors, liners, transformers, radio insulation, and motors.

- Use Teflon’s low refractive index to make optical fibers.

- Some parts of loudspeakers, microphones, and robots can be made using Teflon.

7. Engineering Industry

Teflon use in the engineering industry is seen in almost all areas for these reasons:

- Teflon has a high level of resistance to corrosion. This makes it very easy for the industry to trust that parts coated with Teflon will last very long.

- Teflon has a high level of tensile strength. This makes its use in the engineering industry appropriate.

- PTFE’s dimensional stability also comes in to help make its use in this industry worth it.

Major applications in this industry include:

- Bearings

- Seats and plugs.

- Pipe coatings

- Surfaces that are non-stick

- Coatings for fittings, pump, and valve components.

8. Solar Panel Manufacturing Industry

- Since Teflon can withstand high temperatures of 260oC maximum, it works perfectly for this industry.

- Teflon comes with fine light and ultraviolet resistance features.

- It also has very good weather resisting and strong resisting features to cold and heat.

- They are used due to their nature of being very durable.

- Water resistance properties in Teflon help a lot as well.

The different applications:

- Coating solar panel release sheets

- Solar laminators

9. Industrial Machining Manufacturing Industry

What difference will Teflon make in the making and use of industrial machines?

- Teflon’s ability to lubricate is what makes it easier for machines to work smoothly and last long too.

- PTFE comes with properties designed to cut down friction whenever machines are being used or moving. This makes it hard for wear and tear to be experienced.

- Teflon is resistant to different industrial chemicals such as gasoline, ammonia, sulfuric acid, amyl alcohol, chlorine, sodium hypochlorite, petroleum oils, etc.

- PTFE enhances the operation abilities of machines.

Some of its applications here include:

- O-rings

- Saw blades.

- Joints, sliding plates, and gears.

- Bushings, pipe linings, etc.

PTFE is available in many forms including PTFE rods and PTEF sheets for your unique application requirements.

Conclusion

Out of all fluoropolymers, Teflon or PTFE is the finest. Due to its unique properties of resisting corrosion, and water, and being strong, it is used in a lot of industries.

All you need to do is to ensure you buy them from the right retailers or wholesalers to move your business to the next level.