To ensure the best fluid sealing needs are met, some packing methods are necessary. With a long list of these methods of packing, graphite and PTFE packing is very famous.

Although both work out well to meet their individual sealing needs, the knowledge about their uniqueness helps a lot.

Comparing PTFE Packing vs Graphite Packing Properties

Graphite packing

Material

PTFE is also known as polytetrafluoroethylene.

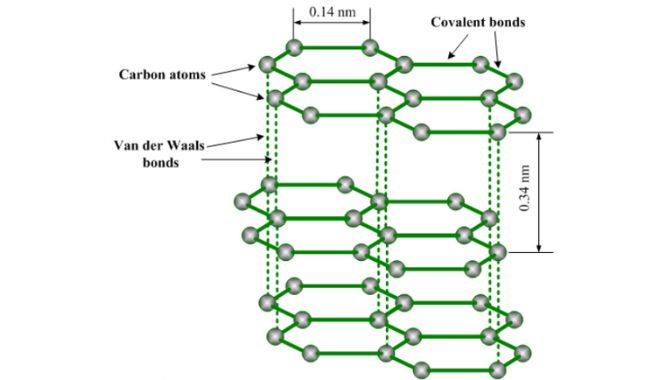

Graphite is as pure carbon in its inorganic form.

Color

Graphite packing – The color is black. It comes fully in braided sealants. This color comes from being made from pure or authentic carbon.

PTFE has a synthetic polymer that is white in color. Through the process of tetrafluoroethylene polymerization, it is obtained.

Finishes or Additions

It is possible to blend Graphite packing with other elements to enhance its features greatly.

To achieve a great flexible finish with Teflon or PTFE, lubrication of yarns is introduced.

PTFE packing

Friction Levels

PTFE coefficient friction is low.

Graphite packing comes with a friction coefficient that is very low.

Chemical Resistance

PTFE is able to resist different substances kinds as acids, other gases, harsh chemicals, etc. It is also perfect for uses where wide pH ranges within the system are expected.

Graphite packing resists almost every inorganic media like most bases and acids.

Temperature Limits

Graphite packing has the finest heat-conducting abilities. However, it should not be used where strong oxidization, particularly at high temperatures, is present.

PTFE packing is a poor heat conductor. It takes in heat. Can withstand temperatures to a specific degree like 240oC.

Cost

Graphite packing is more affordable than PTFE packing.

Teflon

Health and Safety

PTFE packing is very clean, graphite free, and comes with no contamination.

Graphite packing is healthy and safe based on the applications they are used for.

Maintenance

Graphite packing doesn’t require much maintenance cost because it self-lubricates.

PTFE packing can last very long. This feature reduces its maintenance downtime, cost, and the cost of regular maintenance needed.

Flushing

Graphite doesn’t need to be flushed in most of its applications.

PTFE packing doesn’t need flushing as well.

Installation & Removal

PTFE is very easy to install and remove when it is required.

Graphite packing comes with similar simplicity in installation and removal.

Graphite structure

Application of PTFE Packing vs Graphite Packing

Chemical Industries

Graphite packing – is used more in equipment that handles acids. It is used also in valves, shafts, agitators, chemical moving equipment, and others.

PTFE packing can be found to be used more in shafts, valves, impellers, rolling mills, etc.

Oil and Gas Industries

PTFE packing – for coating pipes, seats, plugs, valve components, rotating shafts, etc.

Graphite packing – for or in pumps, pipes, tanks, etc.

Food and Beverage Industries

Graphite packing – It has a self-lubricating feature. This makes it stay strong no matter the temperature levels. Due to this, it is clean and free from bacteria always.

PTFE packing is FDA-approved. Some applications include temperature casings, conveyors, etc.

Pharmaceutical Industry

PTFE packing – you will find in the varying types of pumps and valves. This is mostly based on the job it will be used for.

Graphite packing based on the needs of the client can be used in various pumps and valves as well.

Aerospace Industry

Graphite packing is used here because this industry necessitates elevated pressure, excellent shaft speeds and a higher level of temperature involvement. They are used in systems with valves, stuffing boxes, faucets, etc.

PTFE packing is in countless applications here like flaperons, elevators, braking systems, fuel systems, pneumatic systems, thrust reversers, etc.

Conclusion

Being able to compare the two and knowing what each offer is a benefit to you. It helps you to know for sure which packing will work for you. Also, you can always make the right call.

Check out the best wholesalers to make sure the right packing type is purchased to meet your needs.

More resources:

Graphite – Source: Wikipedia

Graphite Packing – Source: HANSA

PTFE Packing – Source: HANSA

PTFE Applications – Source: HANSA