The Main Properties of PEEK Sheet

- PEEK is one of the most heat-resistant materials, able to handle working temperatures as high as 250 to 260°C (about 482 to 500°F).

- PEEK has extremely high flexural strength—at room temperature, it’s about 10 times stronger than PTFE and can reach between 150 and 330 MPa.

- PEEK is naturally flame-resistant. Even when it’s heated beyond its melting point, it only gives off a small amount of smoke and toxic gases.

- PEEK is highly resistant to chemical corrosion and wear. It combines the corrosion resistance of PTFE with the wear resistance of metals.

Description about PEEK Sheet from Hansa

Hansa PEEK is considered the “benchmark of performance” among specialty engineering plastics. It offers outstanding overall performance and can function reliably in harsh environments where traditional plastics would fail.

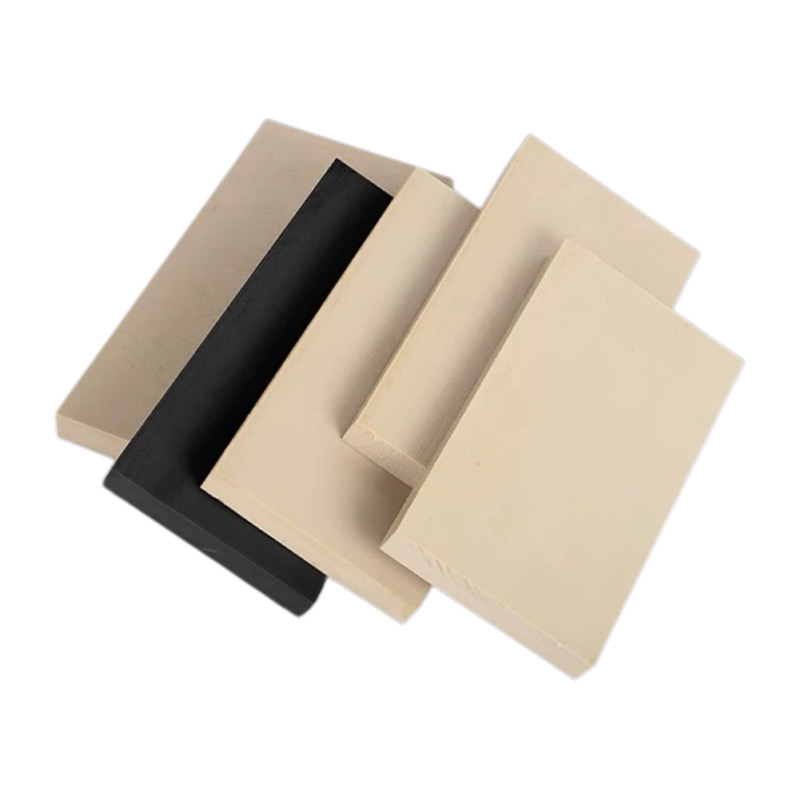

The Color of PEEK Sheet

The color of PEEK sheets varies depending on the specific product. Currently, we offer five different types of PEEK sheets, primarily distinguished by their fillers:

- 100% pure PEEK, without any additives, resulting in a light beige color.

PEEK sheets with 30% glass fiber, which is white, resulting in a light brown or brownish-gray color when mixed with the PEEK material. - PEEK sheets with 30% carbon fiber, which are black, and the fibrous texture of the carbon fiber is visible when cut.

- PEEK sheets with 30% carbon fiber, graphite, and PTFE; the color is also black. Although PTFE is white, its presence doesn’t significantly affect the color when mixed with the two black components.

- ESD PEEK sheets, most of which are black, although a very small number are the natural light beige color, which are specially customized.

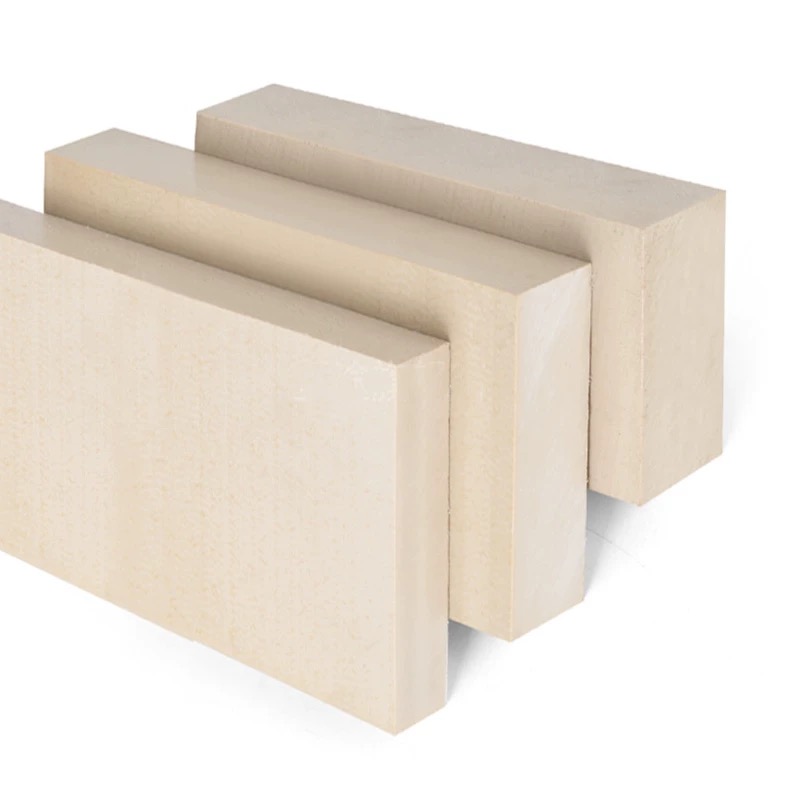

Standard to Cut to Size Dimensions and Thickness

PEEK sheets are available in a full range of specifications, with standard sizes readily in stock and shipping within 3-7 days. HANSA is deeply committed to technological innovation, having increased the maximum width of PEEK sheets from 600 mm to 1250 mm. The standard thickness is 60 mm, but we can produce sheets up to 100 mm thick, maximizing our ability to meet your size requirements.

Hansa is the manufacturer, and you can request the sheets to be cut to any size. We will do our best to accommodate your needs.

Other Modified PEEK Sheet

- Glass-Filled PEEK Sheet

- Carbon-Filled PEEK Sheet

PEEK Sheet

PEEK performs reliably in extreme temperatures, with a continuous operating range from -269°C to 260°C, and a melting point around 340°C.

Even at high temperatures like 250°C, it maintains over 100 MPa tensile strength and 170 MPa flexural strength.

Resistant to strong acids, alkalis, and organic solvents — plus, it’s naturally flame-retardant.

Thanks to its high stiffness, PEEK can withstand long-term use under various wear conditions.

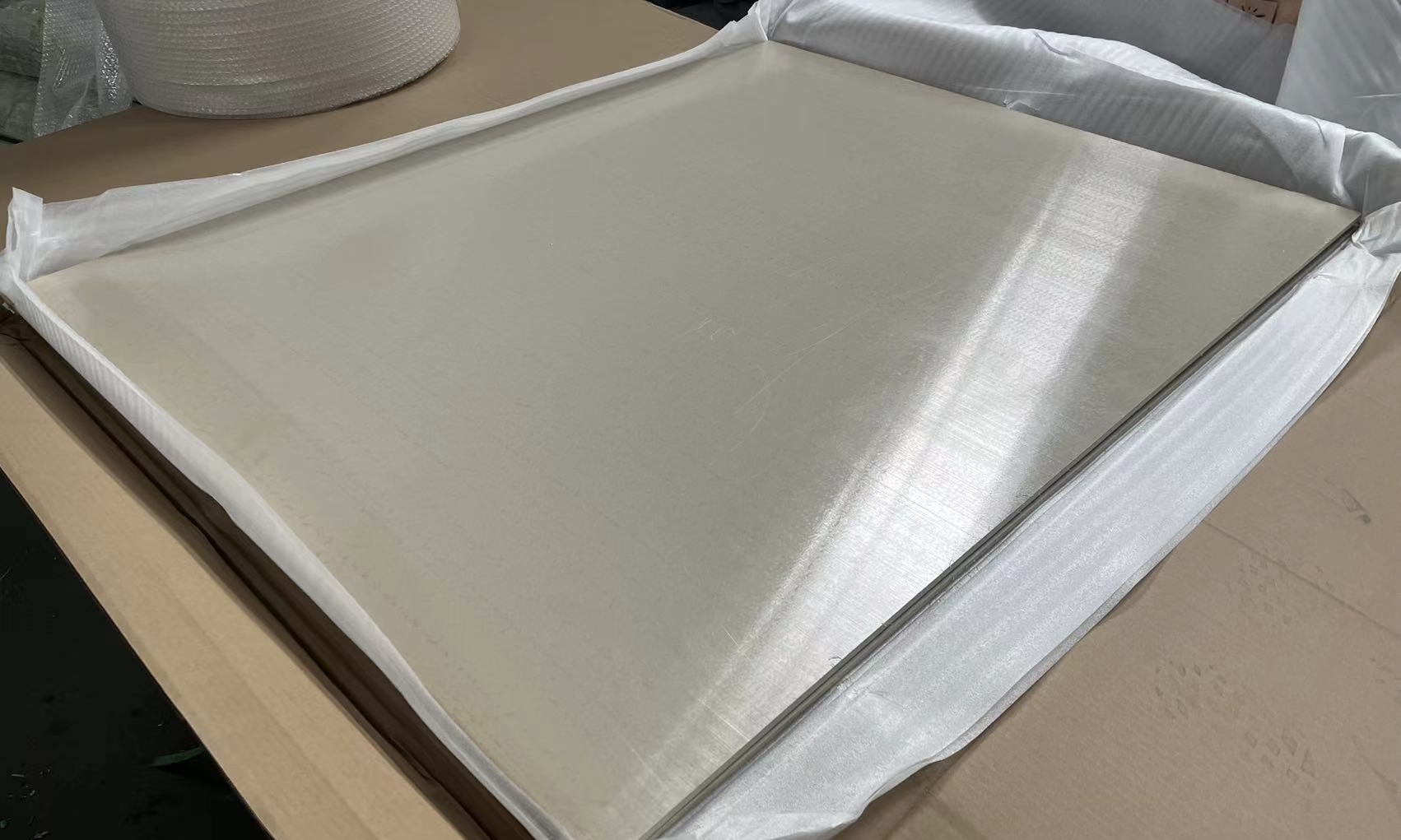

The Shipping Process at Hansa

Hansar has its own manufacturing facility and independently produces PEEK products. We are a direct manufacturer and supplier — no middlemen involved.

Every product goes through two rounds of quality inspection before packaging to ensure top-notch quality.

For large orders, we typically use wooden crates. For smaller or lighter items, we use sturdy cardboard boxes. All products are carefully protected with foam wrap to prevent any damage during transit.

Hansar has a well-established logistics network and reliable shipping partners. Whether by sea, air, or rail, we ensure your goods are delivered safely and on time.

In addition to custom parts, we keep a large stock of standard PEEK components in various specifications — ready for immediate shipment with no lead time.

Specifications Of PEEK Sheet From Hansa

- Specification Sheet

- Physical Properties

| Product | Size | Thickness/(mm) | Weight per sheet/(kg) |

| PEEK Sheet Natural | 6*600*1240 | 6.9 | 6.85 |

| 8*600*1240 | 8.8 | 8.81 | |

| 10*600*1240 | 11.2 | 11.14 | |

| 12*600*1240 | 13.2 | 13.33 | |

| 15*600*1240 | 16.2 | 16.24 | |

| 18*600*1240 | 18.84 | 20.16 | |

| 20*600*1240 | 21.3 | 21.14 | |

| 25*600*1240 | 26.5 | 26.67 | |

| 30*600*1240 | 32.7 | 32.66 | |

| 35*600*1240 | 37.5 | 37.35 | |

| 40*600*1240 | 42.5 | 42.57 | |

| 50*600*1240 | 53.2 | 53.29 |

| Properties | Testing Method | Unit | Result |

| Tensile Strength(23℃) | ISO 527 | MPa | 95 |

| Elongation(23℃) | ISO 527 | % | 35 |

| Melting Point | ISO11357 | ℃ | 343 |

| Conductivity | ISO /CD22007-4 | W/(mK) | 0.29 |

| Dielectric Strength(2mm) | IEC 60243-1 | kV/mm | 20 |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 |