Graphite Filled PTFE

Graphite-filled PTFE exhibits superior lubrication properties. Therefore, PTFE filled with graphite is suitable for applications where friction should be near zero. You can also refer to this graphite-filled PTFE as self-lubricating material.

Remember, graphite is a type of carbon. Still, Teflon filled with graphite guarantee the lowest friction coefficient. But they tend to have slightly low wear resistance. Also, graphite tends to leach out.

Apart from graphite, these PTFE materials may have:

- Carbon fillers

- Glass fillers

Custom Graphite Filled PTFE

Generally, graphite-filled PTFE chemical compatible degree compares to virgin PTFE. The same applies to the graphite-filled PTFE temperature range (between-240 and 260°C).

Additionally, these filled Teflon materials are available as graphite-filled PTFE sheets, graphite-filled PTFE rods, graphite-filled bars, or any custom geometrical shape you want.

The amount of graphite in PTFE varies between 5% and 15%

Applications of Graphite Filled PTFE

Graphite-filled PTFE gaskets –reduce static energy build-up, while perfectly mating uneven surfaces. They are perfect for surface plated with chromium and steel.

Graphite-filled PTFE O-ring – due to their chemical resistance, superior chemical properties, graphite-filled PTFE rings are suitable for both industrial and domestic applications.

Self-lubricating bearing – graphite lowers the coefficient of friction. It makes the PTFE bearings lubricate themselves. This reduces possible friction and wear. Besides, it has excellent load-bearing capacity even at high speed.

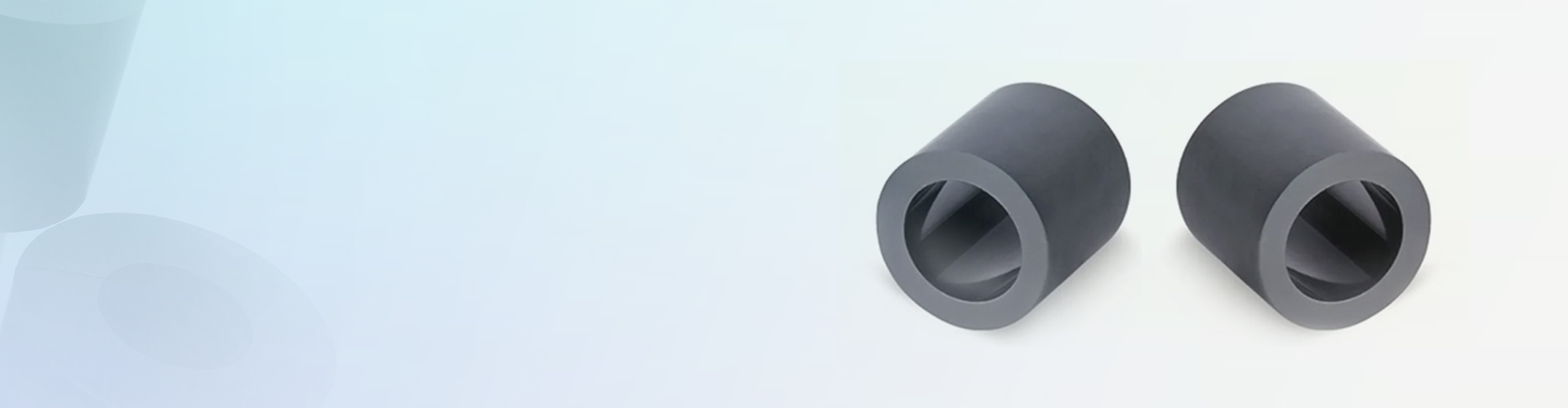

Graphite-filled PTFE bushings – suitable for self-lubricating and dynamic loading applications.

- Performance Table

| DATA SHEET | ||||

| PROPERTY: | (MEASURING METHOD:ASTM D4894) | |||

| 80%PTFE+15%GLASS FIBER+5%GRAPHITE | 75%PTFE+20%GLASS FIBER+5%GRAPHITE | 85%PTFE+15%GRAPHITE | unit | |

| SPECIFIC GRAVITY: | 2.20±0.02 | 2.20±0.02 | 2.16±0.01 | g/cm3 |

| TENSILE STRENGTH: | 18±3 | 14±3 | 20±3 | Mpa |

| ELONGATION: | 250±50 | 200±50 | 200±50 | % |

| BULK DENSITY: | —— | —— | —— | g/l |

| HARDNESS: | 54-56 | 54-56 | 54-56 | shore D |

| FLOW-ABILITY: | —— | —— | —— | sec/50g |

| AVE.PARTICLE SIZE: | —— | —— | —— | micron |

| SHRINKAGE: | 1.6-2.6 | 1.4-2.4 | 1.8-2.8 | % |

| PRESSURE | 400 | 400 | 400 | kg/cm2 |

| MAX SINTERING TEM. | 380 | 380 | 380 | ℃ |