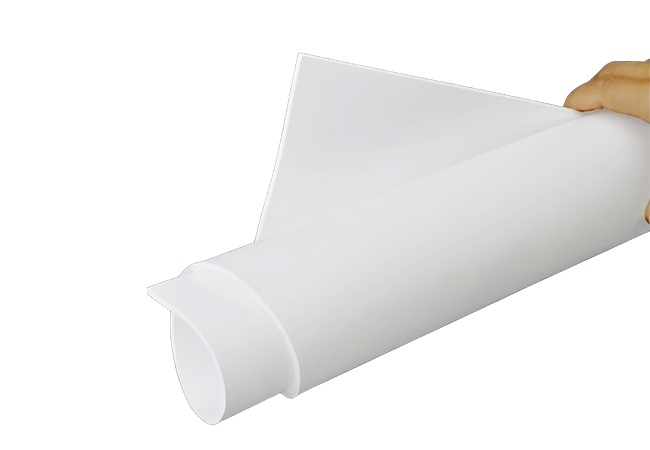

Feuille de PTFE expansé

- Superior thermal and high working temperature

- Exhibits higher strength than normal PTFE

- Does not creep easily

- Can withstand high load

- Excellent recovery even after compression

- Suitable for applications with fluctuating temperature

- It is easy to modify depending on the hardness, or surface energy requirement

- Cold flow phenomenon is relatively low

- You can cut EPTFE sheets easily

Description about Expanded PTFE From Hansa

ePTFE sheet, engineered through a patented freeze-extrusion and rapid biaxial stretching process (U.S. Patent 5,476,589), constitutes a microporous architectural polymer derived from high-purity PTFE resin (ASTM D4894 Grade 3). This innovative material synergizes PTFE’s inherent advantages:

These expanded PTFE sheets come in varying thicknesses and cut-to-size dimensions.

Exhibits corrosion resistance capable of withstanding aggressive agents and the majority of chemical media (pH 0-14).

High tensile strength, compressibility and resilience, can partially recover the original state under pressure, suitable for sealing applications.

Operational range spans from -200°C to +260°C for sustained service, with short-term exposure tolerance up to 300°C.

Porous structure : a porous network formed by stretching to form microfiber connections, with adjustable porosity (usually 30%~90%), both breathable and hydrophobic.

Expanded PTFE Sheet Applications

EPTFE sheets play a crucial role in many industries such as:

- Expanded PTFE gaskets due to low leakage rates even in fluctuating temperature applications. Additionally, it conforms well on uneven surfaces.

- Electrical insulation due to excellent thermal resistant properties and low dielectric constant

- Chemical tank lining since EPTFE is inert

- Medical and food industry products since it is safe and approved by the FDA

- Sealing application due to the unique structure that is fibrous. It can perform well under high-pressure conditions.

- Perfect for applications where there is limited torque for bolt load

- Applications requiring exceptionally compressible sealing since it is made from 100% virgin PTFE

- Specifications of Expanded PTFE Sheet

- Material Property Comparison Chart

- Key Technical Properties of ePTFE

| Item | Details Specification |

| Feuille de PTFE expansé | Thickness: 0.5mm- 10mm, width and length: regular 1500*1500, also can customized in rolls |

| Expanded Tape | Thickness : 1.5mm – 10mm, Width: 1/8”-1”(3mm – 25mm), length in 5M,8M,15M,20M,30M or as request |

| Expanded Rope Cord | Diameter: 1mm – 25mm , Length : in rolls |

| Expanded Tube | Regular size : 1.7* 0.9/ 2.3*1.5/4*2/6*4/3.5*2.5/3*2/12*10…… |

| PTFE Thread Tape | Regular size : Width 20/25/30/50,Thickness is around 0.2mm, Oil and without oil |

| Characteristic | Expanded PTFE (ePTFE) | Standard PTFE Sheet |

| Microstructure | Porous fibrillated network, lightweight | Dense, higher Shore D hardness |

| Flexibility | Excellent (ASTM D790 bending radius <2t) | Rigid, prone to stress cracking |

| Gas Permeability | High (>1.0 mL/min·cm² @ASTM E96) | Non-permeable |

| Mechanical Strength | High longitudinal tensile strength (≥35 MPa)* <br> Lower transverse strength | Isotropic properties (20 MPa avg) |

| Property | Technical Specifications |

| Chemical Inertness | Resists concentrated acids (H2SO4 98%), alkalis (NaOH 50%), oxidants (HNO3 68%), and organic solvents (DMSO/THF) per ASTM G31-12a testing protocol. Reactivity Class 0 per ISO 1817:2022. |

| Thermal Stability | Continuous service range: -200°C to +260°C (long-term)<br>Short-term exposure: +300°C/2h (ASTM D794 cyclic aging test) |

| Tribological Behavior | Ultra-low dynamic friction coefficient (μ=0.05-0.10 @ 0.3 MPa, ASTM D1894)<br>Self-lubricating with wear rate <10^-6 mm³/N·m (Pin-on-Disc, ISO 7148-2) |

| Porous Architecture | Fibrillated micropore network:<br>・Porosity: 80-95% (Hg intrusion per ISO 15901-1)<br>・Pore size distribution: 0.1-50 μm (SEM validated)<br>・Hydrophobicity: Contact angle >140° (ASTM D7334) |

| Biocompatibility | USP Class VI & ISO 10993-5 certified<br>FDA 21 CFR 177.1550 compliant for implantables<br>Non-pyrogenic (LAL test <0.25 EU/mL) |

| Flexural Performance | 80% lower modulus vs. virgin PTFE (ASTM D790) <br>Conformability: ≤0.5 mm bend radius without cracking (EN 13501-1:2018) |

Produits connexes

Manufacturing Process Flow: ePTFE Sheet Production

- Compounding

▸ PTFE fine powder (ASTM D4894 Type III) blended with 18-22wt% isoparaffin lubricant (ISO 9371B compliance)

▸ Homogenization: Twin-screw mixer @ 30-40°C, ≤500 rpm (CE Safety Directive 2006/42/EC) - Preforming

▸ Cold isostatic pressing: 40-70 MPa (ASTM D4895)

▸ Green stock dimensions: 1000mm×1000mm×(5-50mm) with ≤0.2% dimensional tolerance - Expansion Stretching

▸ Monoaxial stretching @ 300-320°C

→ Draw ratio: 5:1 to 15:1 (machine direction)

→ Strain rate: 100-300%/s (ASTM D4441)

Application Of Expanded PTFE

Medical implants

Because of expanded polytetrafluoroethylene (ePTFE) is pure inert, it can be used in a variety of rehabilitation solutions, including artificial blood vessels and patches for soft tissue regeneration and surgical sutures for vascular, cardiac, general surgery, and orthopedics, benefiting both physicians and patients.

Gasket & Sealant Industry

Expanded PTFE gaskets have good chemical resistance, anti-wear characteristics and strong resistance to high and low temperatures, making them ideal for the transportation and sealing of industrial liquids.

Industrial film technology

Expanded polytetrafluoroethylene (ePTFE) films can be processed into a variety of unique microstructures to produce a range of high-performance filter media with micropores that block particulates and allow air to pass through, and their industrial applications include chemical plants, incinerators, food and pharmaceutical manufacturing, foundry, and more.

Advanced dielectric materials for electronic devices

The inherent low loss and dielectric constant of expanded polytetrafluoroethylene (ePTFE) make it an ideal insulation material for wire and cable applications in many high-performance, challenging applications in the telecommunications, computer, test and measurement, defense, and aerospace markets.