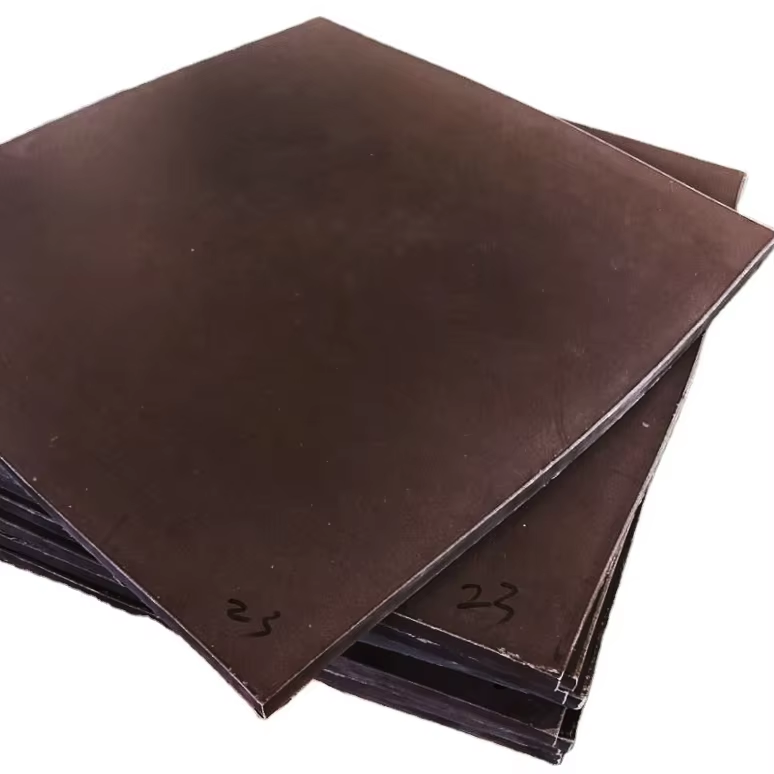

Hansa PTFE 板材

- 用途:适用于各种介质的密封剂和润滑剂,以及各种频率的电气绝缘材料。电容器介质、电线绝缘、电气仪表绝缘。

- 化学加工设备、管道、阀门和反应器的垫片/衬里

- 法兰密封系统、高温/高压(HTHP)密封垫片

- 耐磨部件,用于直线导轨和轴承的低摩擦耐磨垫

- 耐腐蚀衬里、酸槽/电镀槽内衬(例如耐硫酸/硝酸)

HANSA PTFE 板材

Hansa 可为您提供不同类型的 PTFE 板材或薄膜,无论您需要卷材、增强型 PTFE 板材还是定制尺寸,我们都能为您提供优质材料。任何尺寸、任何颜色、任何类型或任何厚度,只需将您的需求发送给我们,即可免费获得样品以检验质量。

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

PTFE 板材种类繁多,可按以下多种方式分类:1. 按制造工艺 2. 按填料/改性 3. 按颜色 4. 按应用 5. 按规格 6. 特殊类型 – 包括多孔 PTFE 板材(通常称为“膨胀 PTFE 板”)

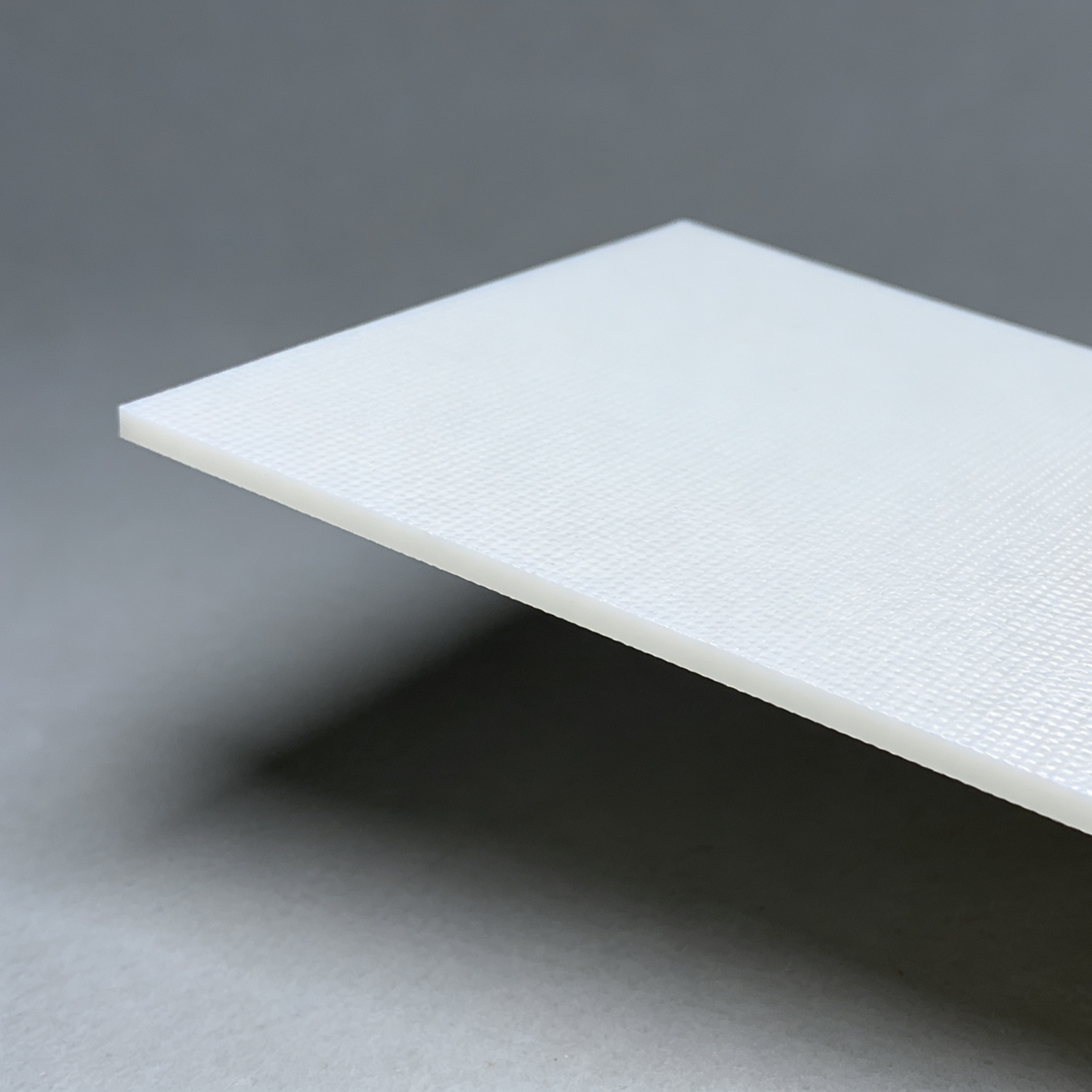

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

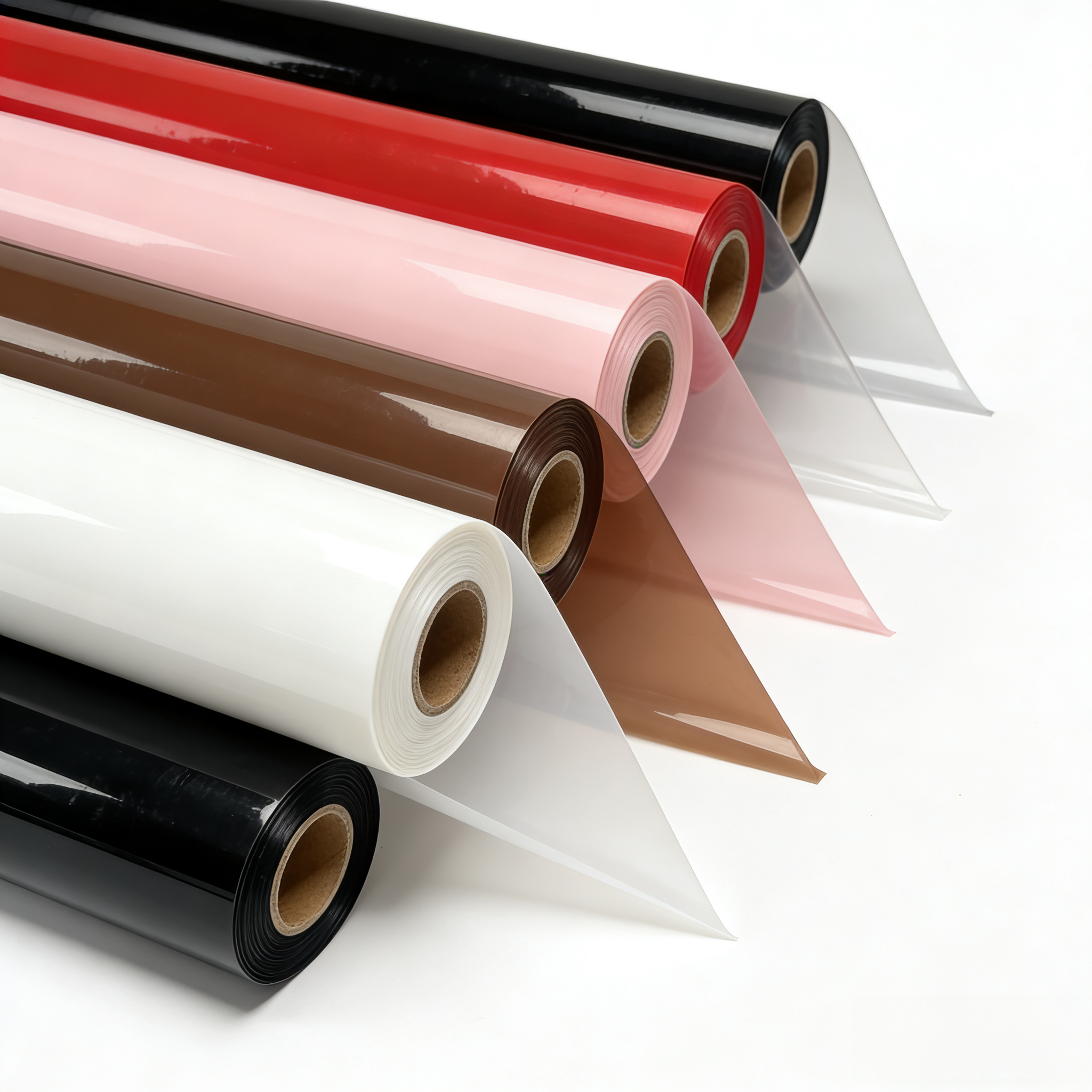

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

PTFE板材的主要特点

在环境温度下表现出良好的抗压和抗蠕变性能,但在高温下可能会软化,适用于低应力应用。

摩擦系数 (COF) 低至 0.04,具有光滑的表面和自润滑性能,无需外部润滑剂。

具有耐腐蚀性能,能够抵抗腐蚀剂和大多数化学介质(pH 0-14)。

持续运行温度范围为 -200°C 至 +260°C,短期暴露耐受度高达 300°C。

PTFE板材的应用

工业的:密封件、垫片、轴承、阀门部件以及管道和储罐的衬里;

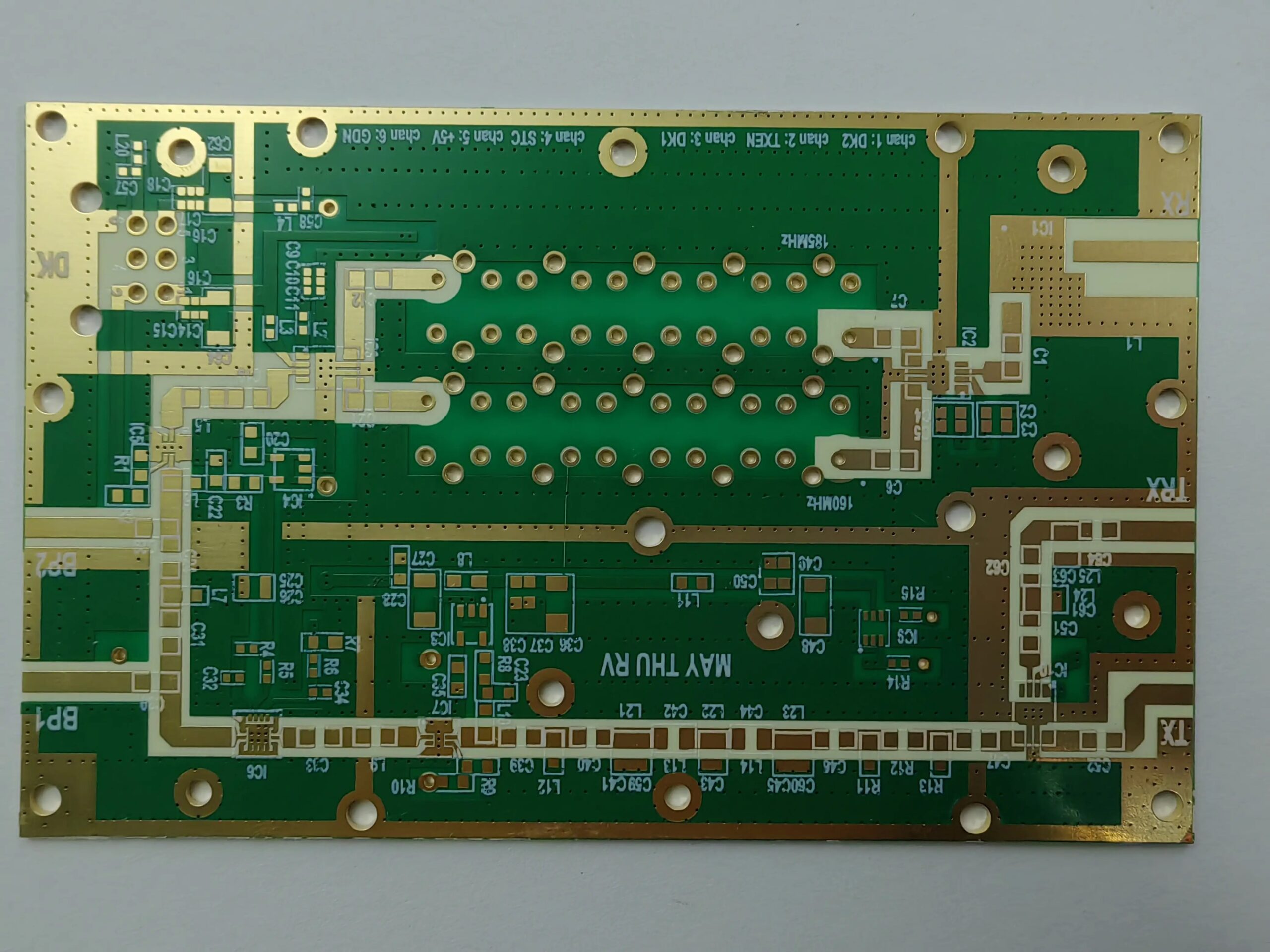

电子产品:电路板、连接器、电子元器件的绝缘;

汽车:燃油管路的衬套、软管和涂层;

食品和饮料:传送带、模具、容器;

医疗的:导管、植入式装置和实验室器皿。

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

Hansa 改性聚四氟乙烯的规格

- 尺寸描述

- 原生PTFE特性

- Etched PTFE Properties

- 改性聚四氟乙烯片材

| 类型 | Size Description |

| PTFE模压板 | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| PTFE车削板 | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| 膨体聚四氟乙烯板 | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| 特性 | 单元 | 结果 |

| 视密度 | 克/平方米 | 2.10~2.30 |

| 拉伸强度(最小) | 兆帕 | 15.0 |

| 断裂伸长率(分钟) | % | 150 |

| 介电强度(最小) | 千伏/毫米 | 10 |

| 特性 | 单元 | 结果 |

| 密度 | g/cm³ | ≥2.18 |

| 抗拉强度 | 兆帕 | ≥30 |

| 断裂伸长率 | % | 300 |

| NO. | Filled Compound And | 拉伸强度Mpa最小 | 极限强度 % 分钟 | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | 20%玻璃纤维 | 10 | 120 | 16 |

| 2 | 25%玻璃纤维 | 10 | 100 | 16 |

| 3 | 20%玻璃纤维 5%石墨 | 10 | 120 | 16 |

| 4 | 60%青铜 | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

相关产品

PTFE片材

聚四氟乙烯片材通常被称为PTFE片材。或者,您也可以称之为特氟龙片材。当然,这两个名称指的是同一种产品,只是“特氟龙”指的是杜邦公司生产的PTFE。

一般来说,这些薄片是由氟和碳键构成的。这就是聚四氟乙烯名称的由来。

由于碳键强,它们被认为是高分子片层。这也是它们在当今许多应用中很常见的原因。

类型 聚四氟乙烯 可用床单

您可以使用广泛的标准对特氟龙板材进行分类。这是因为其具有广泛的定制选项。

理想情况下,你可能想要:

- 带粘合剂的 PTFE 片材 - 其一个表面上带有粘合剂基材

- 按尺寸切割 PTFE 板材 – 根据您的具体要求切割 PTFE

- 不同厚度的板材——您可以选择 3 毫米厚或 100 毫米厚的 PTFE 板材

简而言之,可用的选项取决于独特的定制选项。更重要的是,这也将决定PTFE板材的价格。

通用型PTFE板材

当然,定制化的特氟龙板材适用于非常具体的应用。不过,您也可以选择通用的PTFE板材。

| PTFE板材性能 | 等级 |

| 抗拉强度 | 贫穷的 |

| 抗紫外线 | 好的 |

| 硬度 | 中等柔软 |

| 冲击强度 | 好的 |

| 方面 | 尺寸各异,但可以是 6 x 6 英寸到 48 x 48 英寸 |

玻璃填充聚四氟乙烯板材

如果您正在寻找机械强度、抗冲击性和耐磨性更高的板材,那么选择含有玻璃纤维的板材。通常情况下,这些板材含有约 25% 玻璃纤维。

聚四氟乙烯板材的特点

选择这些床单的原因有很多:

- 高熔点使树脂非常适合大多数持续使用

- PTFE材料在高温下仍能保持稳定。温度范围为-200°C至+260°C。

- 以卓越的防粘性能而闻名

- 卓越的绝缘性能

- 摩擦系数相对较低

- 比标准塑料材料具有更好的耐腐蚀性

- 它们是疏水性的——它们倾向于排斥水

- 化学惰性

- FDA 批准了吗

- 对伽马辐射敏感

有时,您的原生 PTFE 板材无法提供所有这些特性。这是您必须对 PTFE 材料进行增强的原因。这些板材由 100% 纯聚四氟乙烯树脂制成。

让我们比较一下两张有趣的表格:

| 纯聚四氟乙烯片材 | 机械聚四氟乙烯板 |

| · 采用100%纯聚四氟乙烯树脂制成

· 物理性能优良 · 正常应用 · 无需添加任何添加剂 |

· 由再加工聚四氟乙烯树脂制成

· 物理性能低 · 高性能应用程序 · 添加添加剂以改善性能 |

PTFE 片材的运输方式

这些材料有平板状和卷状两种形式。包装方式取决于板材厚度。

大多数情况下,PTFE片材卷的厚度小于0.093英寸。否则,不建议轧制厚度更大的聚四氟乙烯片材。

用途

您可以加工或制造 PTFE 材料板来制造许多零件,例如:

- 聚四氟乙烯垫片

- 聚四氟乙烯衬套

- 聚四氟乙烯衬里

- PTFE滑板

- PTFE电气绝缘零件

- PTFE垫圈