Do you want to learn about labyrinth seals? They offer superior sealing performance and are more wear-resistant than ordinary seals due to their non-contact design, resulting in very low wear. They are widely used in industrial, aerospace, and automotive industries. Next, I will give you a comprehensive introduction to this great invention, the labyrinth seal.

What is the Labyrinth Seal?

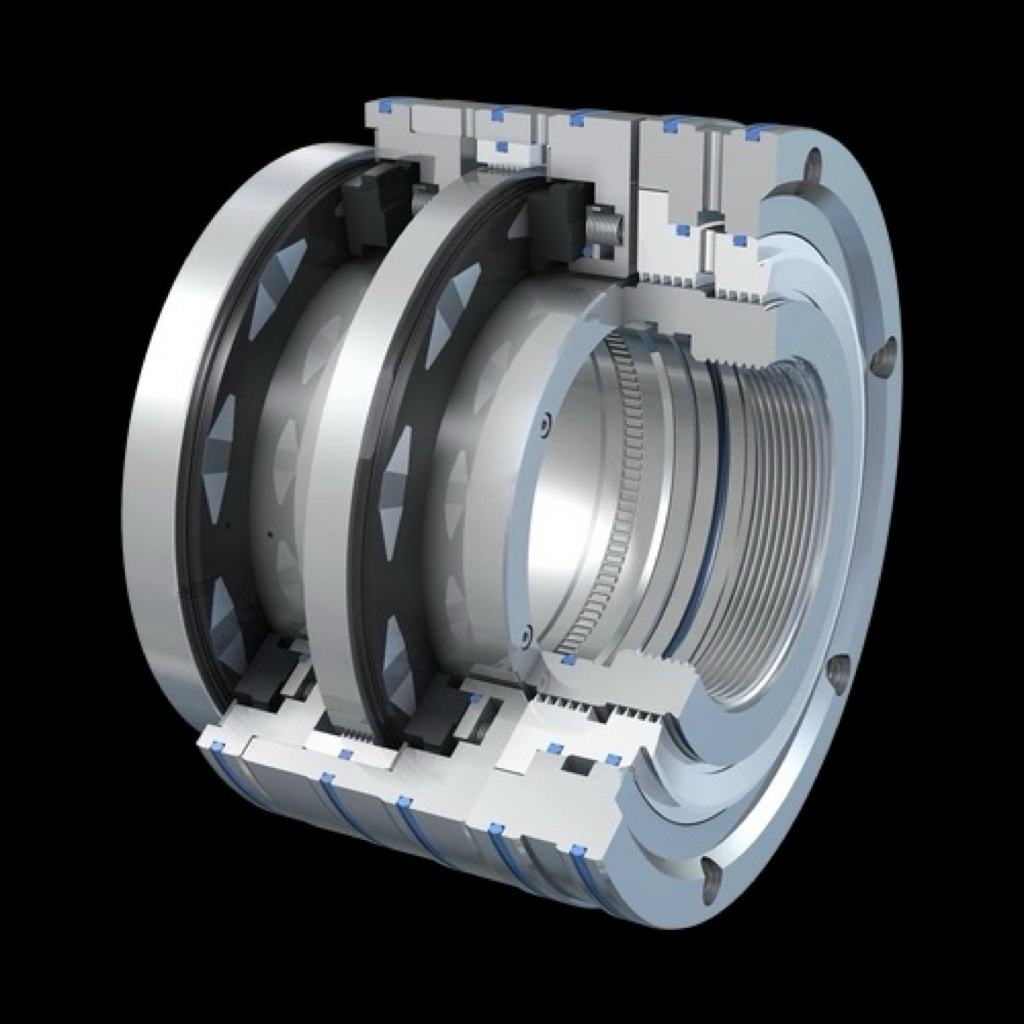

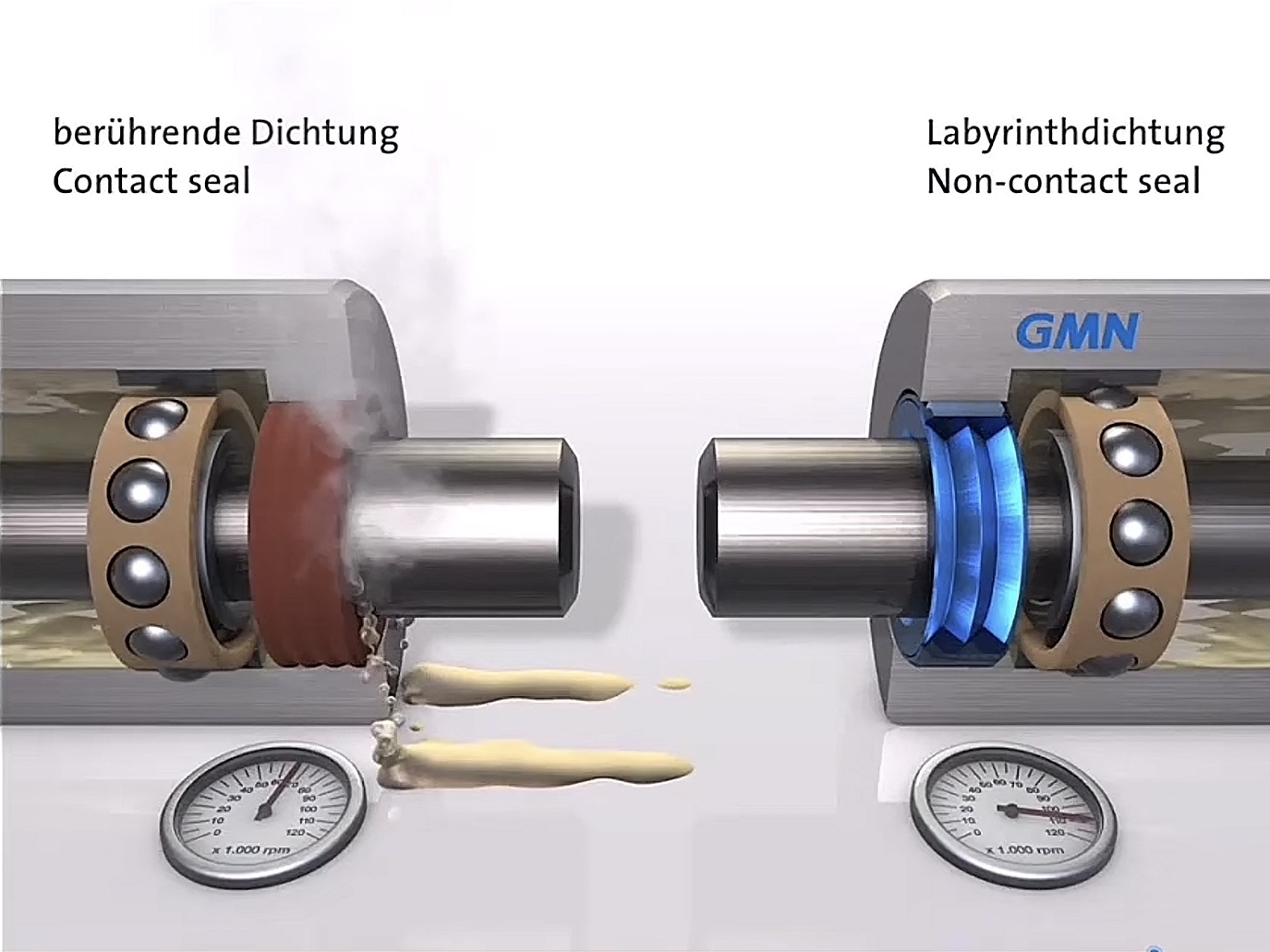

Labyrinth seals, also known as non-contact seals or mini seals, are commonly used in mechanical seals. They are called labyrinth seals because their internal structure is intricate and complex, resembling a maze. Due to their excellent sealing performance, they not only prevent internal gas or liquid leakage but also block external contaminants from entering, making them applicable in numerous fields.

How does it work?

Internal Structure

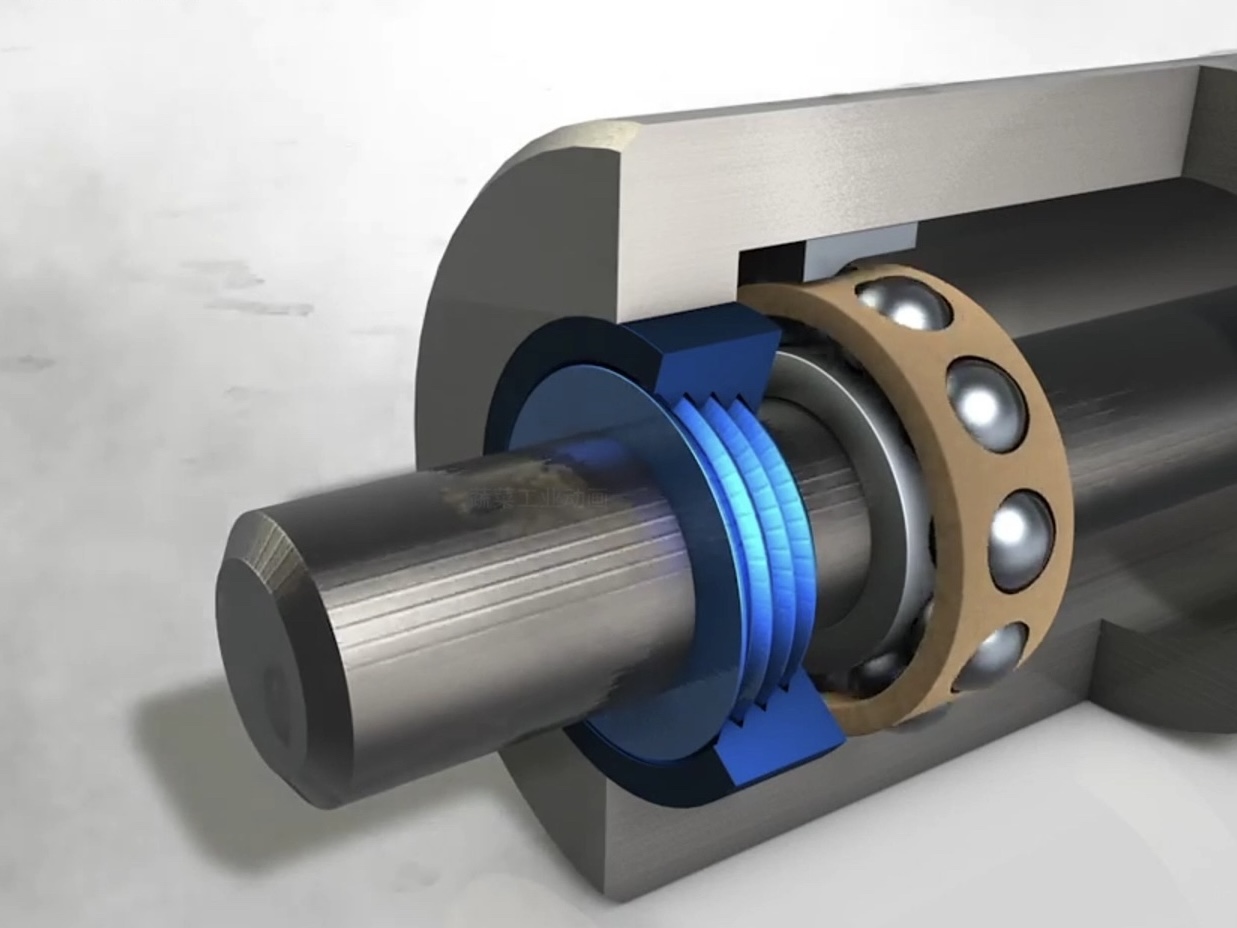

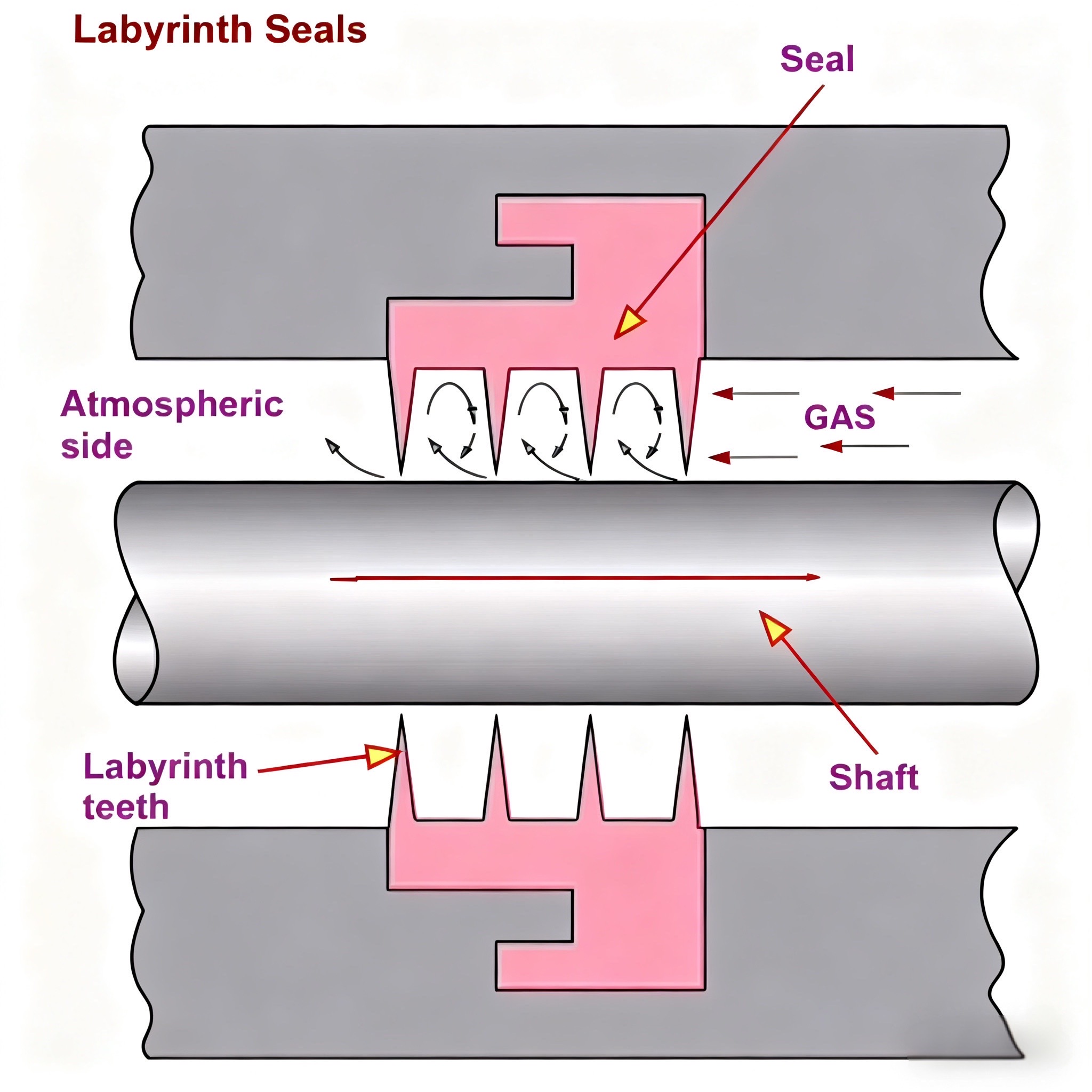

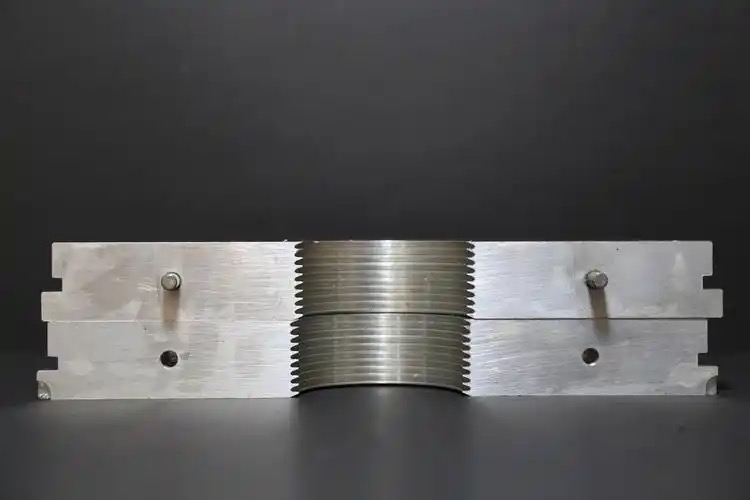

The maze’s sealed design is ingenious.Taking a smooth labyrinth seal as an example, it is fixed on a rotating shaft, with its interior in contact with the medium to be sealed and its exterior connected to the environment. Inside the labyrinth seal are a series of comb-like teeth, the gaps between which are called cavities. These cavities are crucial for allowing the medium to pass through, thus achieving the sealing effect. It’s important to note that the comb-like teeth are not in contact with the rotating shaft; the medium can still pass through.

Working Principle

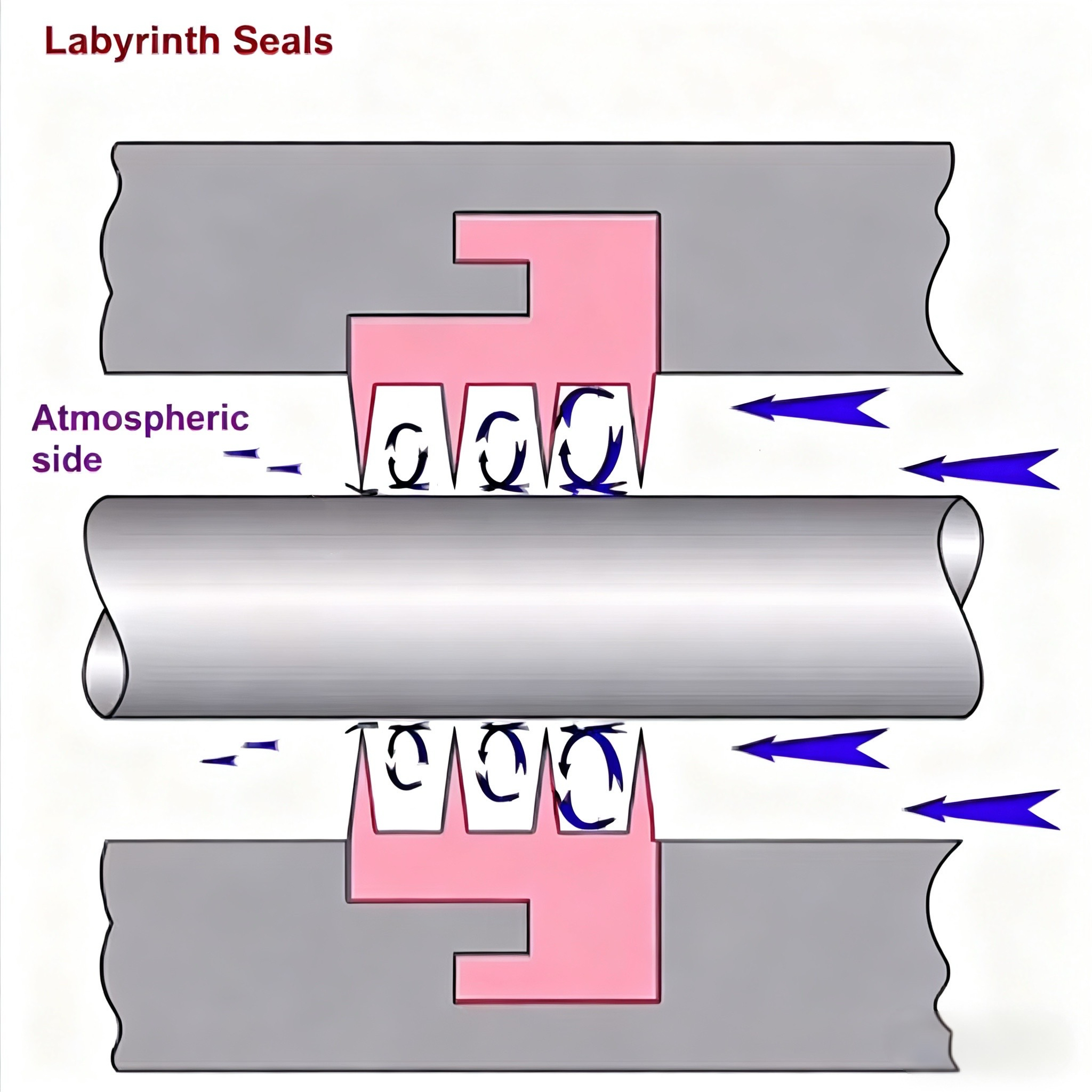

Simply put, it involves guiding the medium to be sealed through a long and winding path, gradually reducing its velocity until it approaches zero, thus achieving a seal.

In technical terms, as the medium passes through the gap between the comb teeth and the rotating shaft, its velocity increases sharply while its pressure decreases, converting pressure into kinetic energy. Then, as the medium enters the cavities, the space expands, forming eddies, further reducing its velocity, and the kinetic energy is converted into heat and dissipated. After passing through one cavity after another, the medium’s velocity approaches zero, and its pressure drops to near atmospheric pressure, thus sealing the other side.

Types of Labyrinth Seal

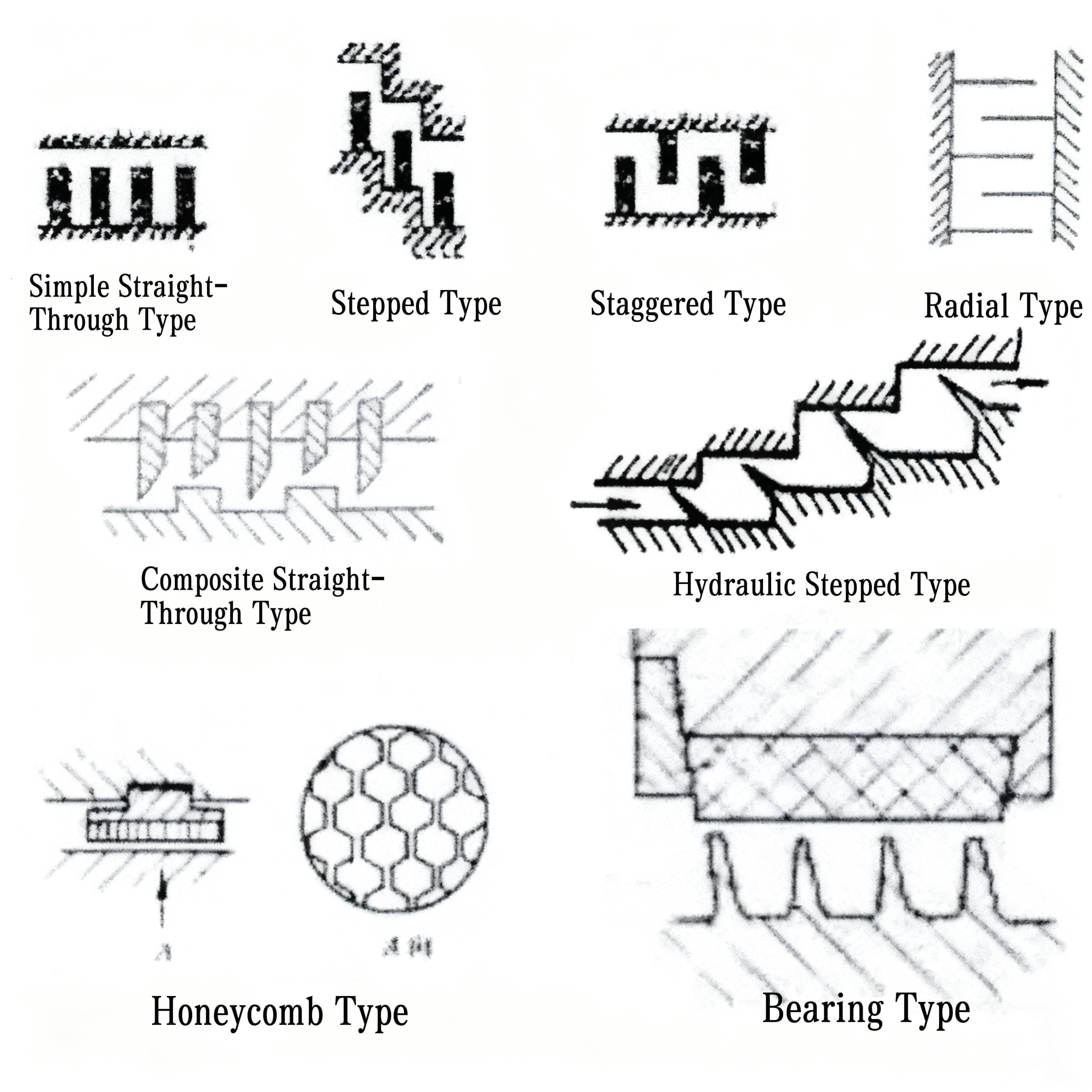

Labyrinth seals are a general term for this type of sealing method, but what you may not know is that labyrinth seals have various physical forms and are therefore divided into multiple types. Below, I will introduce all the types of labyrinth seals to you:

Based on Structural Features:

- Simple Straight-Through Type:

The concave part of this type of seal is parallel to the shaft, resulting in a poor sealing effect.

- Composite Straight-Through Type:

Composed of steps and comb teeth, with long and short comb teeth arranged alternately. A step protruding from the shaft is inserted between two long comb teeth, enhancing the sealing performance.

- Stepped Type:

Distributed in a stepped pattern, like a staircase.

- Staggered Type:

Combs on both sides, arranged alternately, complex structure, strong sealing performance.

- Radial Labyrinth Type:

Combs are perpendicular to the shaft, resulting in a poor sealing performance.

- Hydraulic Stepped Type:

Its comb teeth are arranged obliquely, resulting in excellent sealing performance.

- Honeycomb Type:

The sealing surface is hexagonal honeycomb-shaped, providing a very strong sealing performance.

Based on Comb Shape:

- Pointed teeth, resembling acute triangles, offer better throttling effects than other tooth shapes.

- Flat teeth are more wear-resistant than pointed teeth because of their blunter shape.

- Oblique teeth are often used in composite straight-through labyrinth seals, providing the best sealing effect.

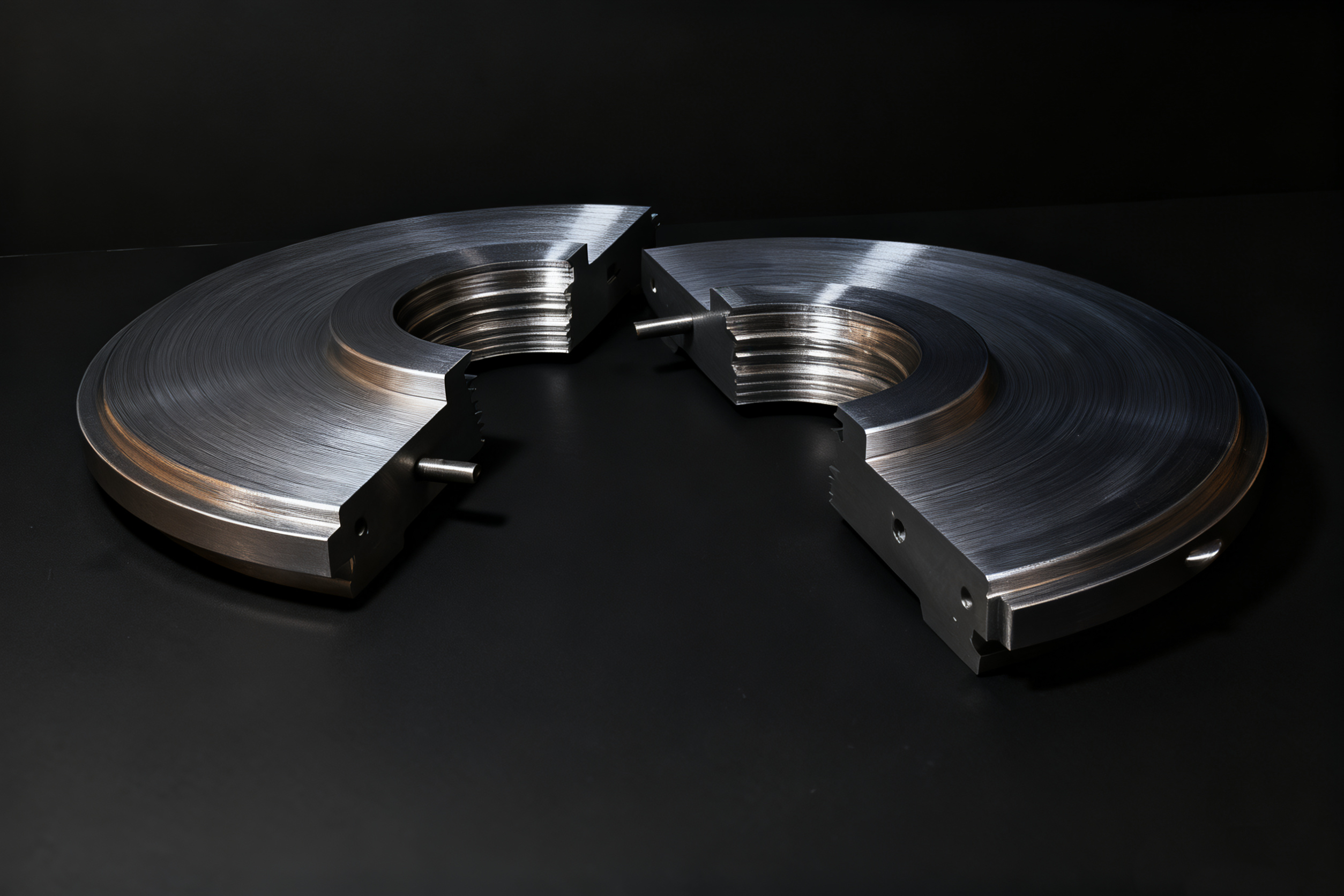

Based on Exercise:

- Fixed labyrinth seals are fixed in place and can only seal in a defined position.

- Floating labyrinth seals, on the other hand, have a certain gap between themselves and the shaft, allowing them to float up and down.

Applications of Labyrinth Seal

- การบินและอวกาศ:

Labyrinth seals are used between turbine blades and the casing in aero engines to seal the high-temperature gases produced by combustion, effectively preventing leaks and safety issues, while also improving engine efficiency.

They can also seal hydraulic and fuel systems, reducing fuel consumption.

- Automotive Industry:

Labyrinth seals are used in engines to prevent oil and coolant leaks from components such as crankshafts and camshafts.

- Used in transmission systems:

They prevent lubricant leaks and contaminant ingress, effectively extending equipment lifespan. They are also used in components such as differentials and drive shafts.

- Chemical Industry:

Labyrinth seals are generally used in high-pressure reactors and flange connections in pipelines to effectively prevent leaks of highly corrosive media or flammable and explosive materials, improving safety.

- Mechanical Engineering:

In the mechanical field, labyrinth seals are widely used in various pumps, compressors, steam turbines, and other rotating equipment. In some engines and hydraulic cylinders, they are used for piston sealing to reduce oil leaks and extend equipment lifespan.

The Advantages of Labyrinth Seal

- As described above, a significant characteristic of labyrinth seals is their non-contact nature, the benefits of which are obvious. Yes, it’s low friction. Because it doesn’t contact the shaft, wear is minimal, unlike traditional seals which rub against the shaft and wear down over time, damaging both the seal itself and the equipment. Labyrinth seals minimize wear, extending equipment lifespan and reducing maintenance costs.

- Labyrinth seals are more leak-proof than ordinary seals. Over time, ordinary seals wear down, reducing their sealing performance, while labyrinth seals maintain stable sealing performance for a longer period.

- They improve production efficiency. When ordinary seals require maintenance, equipment stops, impacting work efficiency. This is rarely the case with labyrinth seals, thus improving efficiency.

- Labyrinth seals also possess the advantages of high temperature resistance, high pressure resistance, and corrosion resistance.

Factors Affecting Sealing Performance

-

Internal Factors:

The structural parameters of the labyrinth seal itself, such as the shape and size of the comb teeth, the gap between the comb teeth, and the gap between the comb teeth and the shaft, are crucial.

As mentioned above, different shapes of comb teeth result in different sealing effects and advantages; larger gaps between the comb teeth will increase the cavity, thus affecting the flow rate of the sealing medium.

-

External Factors:

Rotational Speed: High-speed equipment affects the formation of eddies. Higher speeds result in smaller eddies, faster formation, and a significant decrease in sealing effectiveness.

Pressure: As mentioned above, labyrinth seals ultimately require the sealing medium pressure to be approximately equal to atmospheric pressure. Therefore, excessive pressure differences can lead to leakage and prevent a proper seal.

Temperature: Excessive temperature can deform components, causing seal failure.

Materials for Making Labyrinth Seals

Labyrinth seals are made of either metallic or non-metallic materials, with metallic materials being the most common. The material of its main body, the outer layer of the shaft, can be chosen based on the application. Alloy steel offers sufficient strength and machinability, making it suitable for various situations; nickel-based alloys can withstand temperatures from 600 to 1000 degrees Celsius. The comb teeth in labyrinth seals are typically made of stainless steel, which is rust-resistant, wear-resistant, and corrosion-resistant.

Non-metallic materials often use polytetrafluoroethylene (PTFE), which is heat-resistant and offers many advantages. However, this type of material is only suitable for sealing in low-pressure environments.

Temperature Range of Labyrinth Seal

Different materials used in labyrinth seals have different temperature resistance ranges.

Generally, metal labyrinth seals have a temperature resistance range of 100~600℃, with some metals capable of withstanding temperatures as low as -253℃ in extreme environments.

Common rubber labyrinth seals have a temperature resistance range of -50~250℃, while materials like silicone rubber and fluororubber can maintain stable operation at temperatures of 300℃ or even higher.

Stainless steel labyrinth seals have a temperature resistance range of 800~1500℃, according to some data.

บทสรุป

Labyrinth seals offer superior sealing performance and have a wide range of applications. Different materials and types of labyrinth seals are customized to suit various application scenarios. However, it’s important to note that labyrinth seals may experience slight leakage, but this is within acceptable limits.

This concludes my information about labyrinth seals. If you have any further questions, please contact us. We will patiently and meticulously answer them for you. ฮันซ่า is a company specializing in plastic products with 25 years of manufacturing experience. We are worthy of your trust!

คำถามที่พบบ่อย

What are the disadvantage of labyrinth seal?

The sealing performance of a labyrinth seal is not absolute; it allows for a certain amount of leakage, which is called “controlled leakage.” Spiral labyrinth seals require a large installation space.

What is the difference between labyrinth seal and a lip seal?

They are different objects to be sealed. Labyrinth seals can adapt to high temperature, high pressure and high speed environments, while lip seals cannot and can only work under low temperature, low pressure and low speed conditions. Their working principles are different. Labyrinth seals use the throttling effect to seal through throttling gaps and cavities, while lip seals use the clamping force between the flexible lip and the shaft to seal.

How often should a labyrinth seal be replaced?

Labyrinth seals do not have a fixed replacement cycle because they use a non-contact sealing method with virtually no wear. Under proper operation, labyrinth seals can last for years, or even only need to be replaced when the equipment is replaced. There are exceptions, such as extreme temperatures causing component deformation and reduced sealing performance, or wear on the tips of the comb teeth, in which case replacement is necessary.