PTFE-ark från Hansa

- Användning: Tätningar och smörjmedel för användning i en mängd olika medier, samt elektrisk isolering för användning vid olika frekvenser. Kondensatormedia, trådisolering, elektrisk instrumentisolering.

- Kemisk processutrustning, packningar/foder för rörledningar, ventiler och reaktorer

- Flänstätningssystem, högtemperatur/högtrycks (HTHP) tätningspackningar

- Slitstarka komponenter, slitkuddar med låg friktion för linjära styrningar och lager

- Korrosionsbeständiga foder, syratank/galvanisering av badfoder (t.ex. svavelsyra/salpetersyrabeständighet)

HANSA PTFE-skivor

Hansa kan förse dig med olika typer av PTFE-skivor eller film, oavsett om du behöver PTFE-skivan i rull, förstärkt PTFE-skiva eller tillskuren i storlek, kan vi alltid leverera kvalitetsmaterialet. Vilken storlek som helst, vilken färg som helst, vilken typ som helst eller vilken tjocklek som helst, skicka oss bara ditt krav och få ett gratisprov för att kontrollera kvaliteten.

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

Det finns olika typer av PTFE-skivor som kan kategoriseras på flera sätt: 1. Genom tillverkningsprocess 2. Genom fyllmedel/modifieringar 3. Efter färg 4. Efter applikation 5. Efter specifikationer 6. Specialtyper – inklusive porösa PTFE-skivor (allmänt känd som "expanderade PTFE-skivor")

En mikroporös struktur tillverkad genom en sträckningsprocess, använd i filtrering, andningsbara membranapplikationer och biomedicinska områden.

Storleken anpassas, detaljhandeln är tillåten. MAX WIDTH är nära 3 meter, MAX tjocklek kan nå 10 mm+

Storleken anpassas, detaljhandeln är tillåten. MAX WIDTH kan nå 2 meter, MAX tjocklek är nära 600 mm.

Specialiserade fyllmedelsformuleringar för kallflödesreducering i PTFE med mikropärlor av blått glas, vitt bariumsulfat, gul kiseldioxid.

Ytan på polytetrafluoreten efter natriumbehandling är hydrofil, som kan limmas med vanligt lim för att utöka dess användningsområde.

Tillverkad genom en extruderingsprocess, lämplig för tunnare plåtapplikationer med hög produktionseffektivitet.

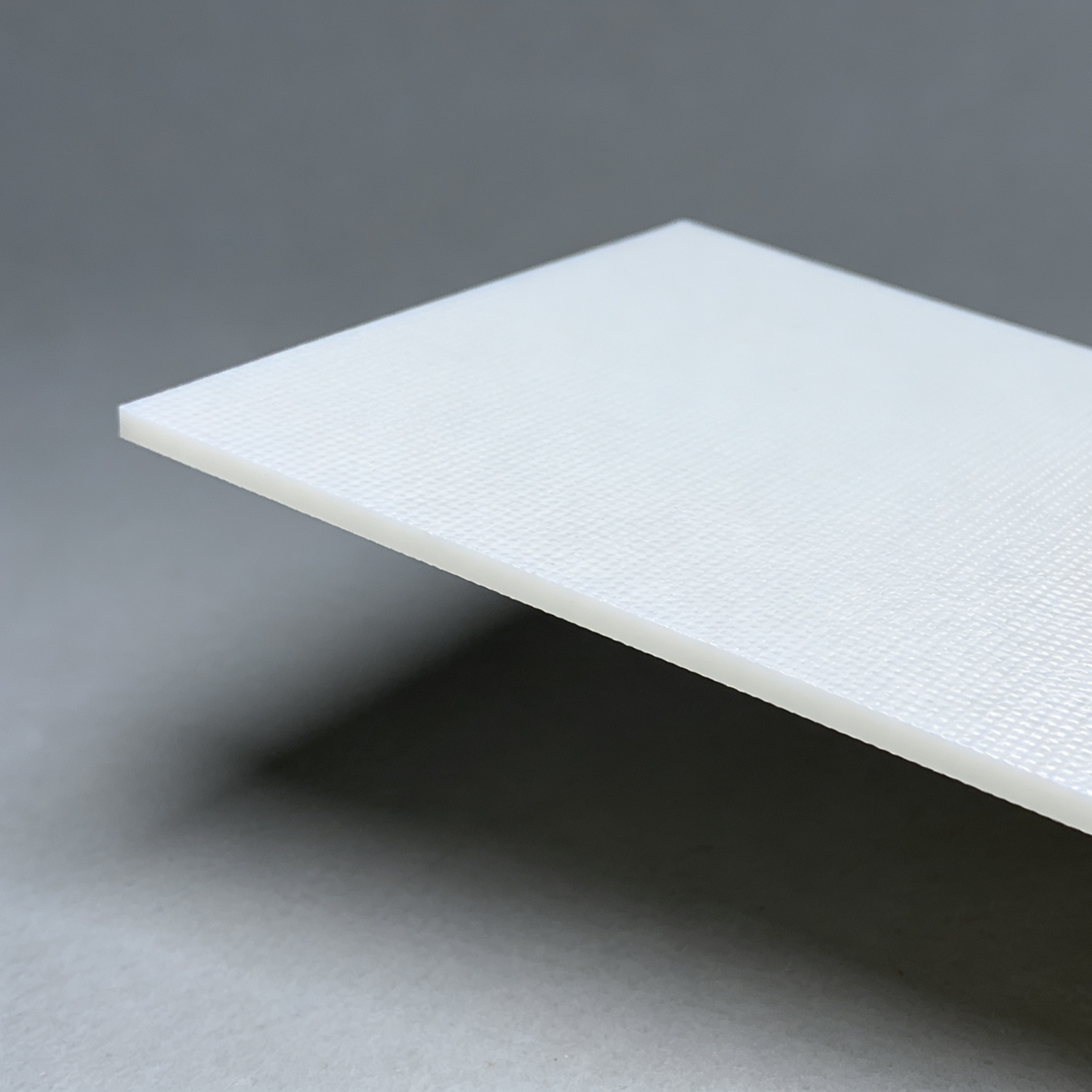

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

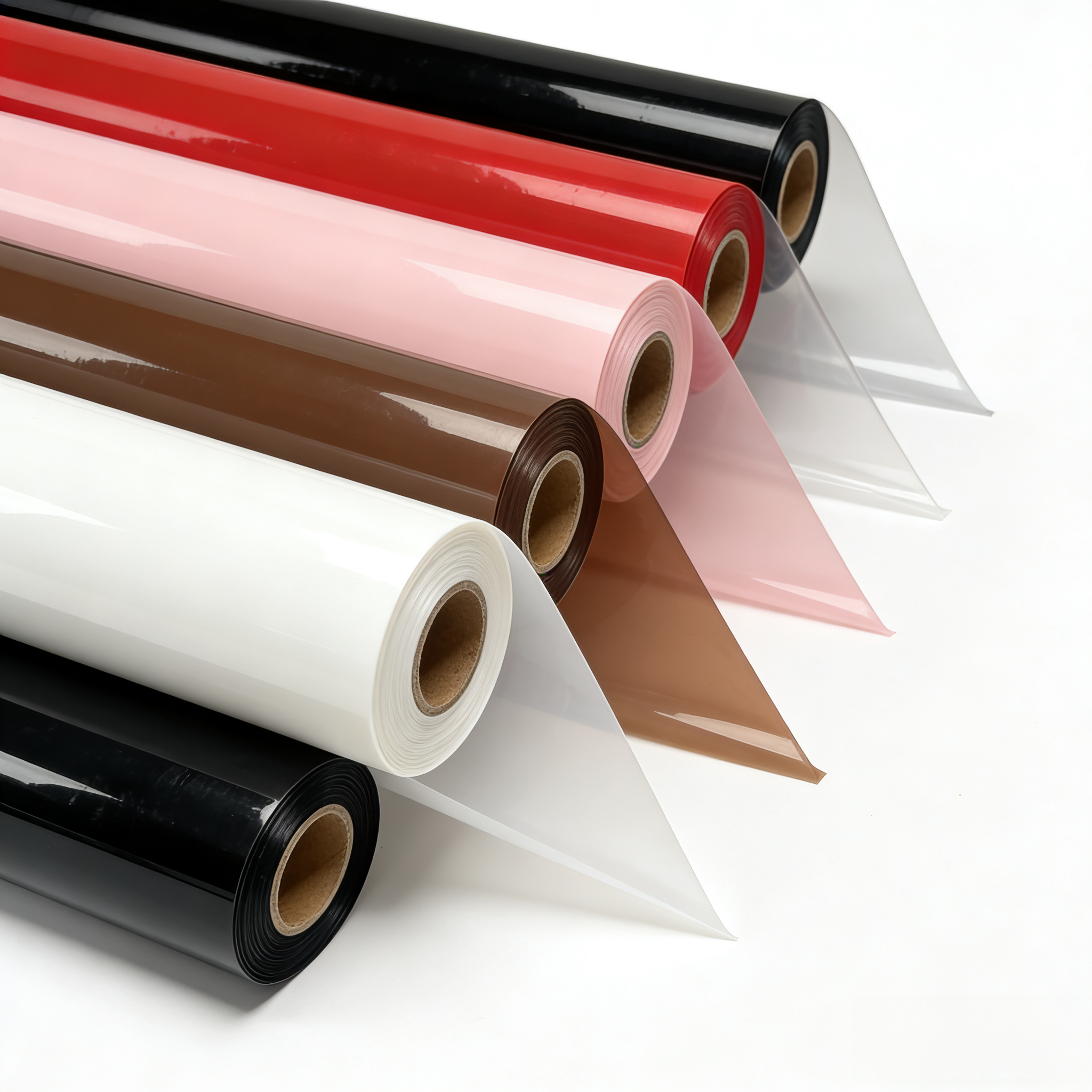

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

Viktiga egenskaper hos PTFE-ark

Uppvisar gynnsamt tryck- och krypmotstånd vid omgivningstemperaturer, men kan mjukna under förhöjda temperaturer, lämpligt för applikationer med låg belastning.

Friktionskoefficient (COF) så låg som 0,04, med en slät yta med självsmörjande egenskaper som eliminerar behovet av externa smörjmedel.

Uppvisar korrosionsbeständighet som kan motstå aggressiva ämnen och de flesta kemiska medier (pH 0-14).

Driftintervallet sträcker sig från -200°C till +260°C för långvarig service, med kortvarig exponeringstolerans upp till 300°C.

Applicering av PTFE-ark

Industriell: Tätningar, packningar, lager, ventilkomponenter och foder för rör och tankar.;

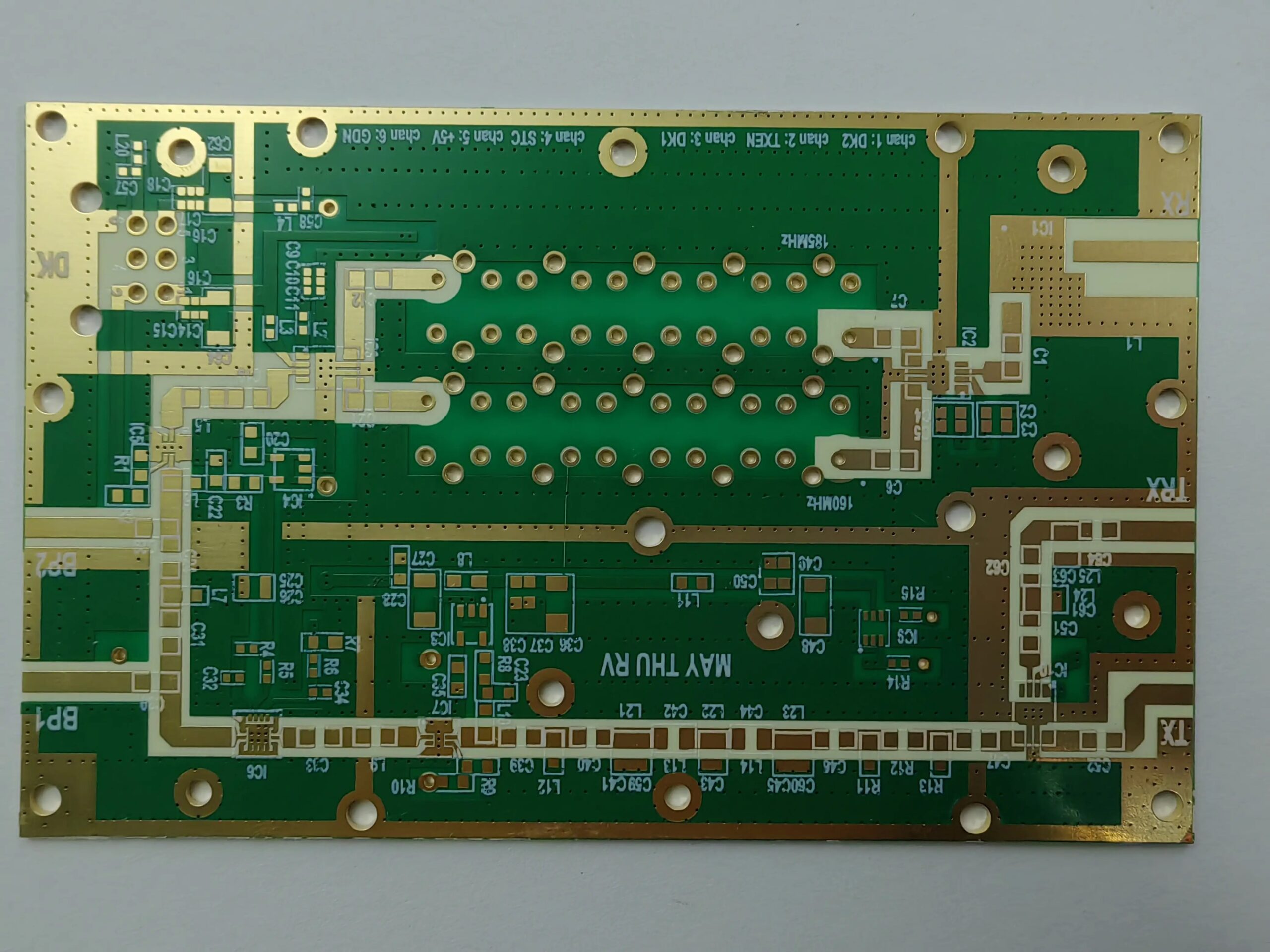

Elektronik: Isolering för kretskort, kontakter och elektroniska komponenter;

Bil: Bussningar, slangar och beläggningar för bränsleledningar;

Mat & dryck: Transportband, formar och behållare;

Medicinsk: Katetrar, implanterbara enheter och laboratorieutrustning.

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

Due to PTFE’s extremely low coefficient of friction (only 0.04) and excellent self-lubricating properties, it is widely used in the manufacture of sliding bearings, guide rails, and piston rings, which can reduce equipment wear and save on production costs.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

Specifikationer för modifierad PTFE från Hansa

- Storleksbeskrivning

- Virgin PTFE Properties

- Etched PTFE Properties

- Modifierad PTFE-skiva

| Typ | Size Description |

| PTFE gjuten plåt | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| Skivad plåt av PTFE | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| Expanderat PTFE-ark | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| Egenskaper | enhet | Resultat |

| Synbar densitet | g/m² | 2.10~2.30 |

| Draghållfasthet (min) | MPa | 15.0 |

| Förlängning vid brott (min) | % | 150 |

| Dieletrisk styrka (min) | KV/mm | 10 |

| Egenskaper | Enhet | Resultat |

| Densitet | g/cm³ | ≥2.18 |

| Draghållfasthet | MPa | ≥30 |

| Förlängning vid brott | % | 300 |

| NO. | Filled Compound And | Draghållfasthet Mpa min | Ultimat styrka % min | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | 20% Glasfiber | 10 | 120 | 16 |

| 2 | 25% Glasfiber | 10 | 100 | 16 |

| 3 | 20%Glasfiber 5%Grafit | 10 | 120 | 16 |

| 4 | 60%Brons | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

Relaterade produkter

PTFE-ark

Polytetrafluoretenskivor kallas för det mesta PTFE-skivor. Eller så kan du också kalla dem teflonplåt. Naturligtvis hänvisar de två namnen till samma produkt förutom att "Teflon" är PTFE tillverkad av DuPont.

Generellt sett är dessa ark gjorda av fluor- och kolbindningar. Det är där den härleder namnet Polytetrafluoroethylene.

På grund av de starka kolbindningarna anses de vara högmolekylära ark. En anledning till att de är vanliga i många applikationer idag.

Typer av PTFE Lakan tillgängliga

Du kan använda breda kriterier för att klassificera teflonplåtar. Det beror på de breda anpassningsalternativen.

Helst kanske du vill:

- PTFE-skivor med lim – de har självhäftande substrat på en yta

- Kapa till storlek PTFE-skivor – PTFE skärs enligt dina specifika krav

- Skivor med varierande tjocklek – du kan välja PTFE-plåt 3 mm tjock eller 100 mm tjock

Kort sagt, de tillgängliga alternativen beror på unika anpassningsalternativ. Ännu viktigare, detta kommer också att bestämma priset för PTFE-plåt.

Allmänt PTFE-plåtmaterial

Självklart gör anpassningen att teflonskivorna passar för mycket specifika applikationer. Du kan dock välja PTFE-ark för allmänna ändamål.

| Egenskaper för PTFE-plåtmaterial | Gradering |

| Draghållfasthet | Dålig |

| UV-beständig | Bra |

| Hårdhet | Medium mjuk |

| Slagstyrka | Bra |

| Mått | Varierar men det kan vara 6 gånger 6 tum till 48 gånger 48 tum |

Glasfyllda PTFE-skivor

Om du letar efter ark med förbättrad mekanisk hållfasthet, slag- och nötningsbeständighet, välj de med glasfiber. I de flesta fall har dessa ark cirka 25% glasfibrer

Egenskaper hos polytetrafluoretenskivor

Det finns många skäl att välja dessa ark:

- Hög smältning gör hartset perfekt för de flesta fortsatta tjänster

- Vid höga temperaturer förblir PTFE-materialet stabilt. Temperaturområdet är -200°C till +260°C.

- Känd för överlägsna anti-stick egenskaper

- Överlägsna isoleringsegenskaper

- Friktionskoefficienten är relativt låg

- Bättre korrosionsbeständighet än standardplastmaterial

- De är hydrofoba – de tenderar att stöta bort vatten

- Kemiskt inert

- Är FDA godkända

- Känslig för gammastrålning

Ibland kommer ditt jungfruliga PTFE-ark inte att erbjuda alla dessa funktioner. En anledning till att du måste förstärka PTFE-materialet. Dessa ark är gjorda av 100% ren polytetrafluoretylenharts.

Låt oss jämföra två intressanta blad:

| Virgin PTFE-ark | Mekanisk PTFE-plåt |

| · Tillverkad av 100% ren polytetrafluoretylenharts

· Höga fysikaliska egenskaper · Normal applicering · Inga ytterligare tillsatser |

· Tillverkad av upparbetad polytetrafluoretylenharts

· Låga fysikaliska egenskaper · Högpresterande applikationer · Fylld med tillsatser för att förbättra egenskaperna |

Blanketter där du kan skicka PTFE-ark

Du kan få dessa material som antingen platta eller rullade. Förpackningsmetoderna beror på plåttjockleken.

I de flesta fall har PTFE-arkrullarna en tjocklek på mindre än 0,093 tum. Annars rekommenderas inte valsning av polytetrafluoretenskivor med högre tjocklek.

Används

Du kan bearbeta eller tillverka PTFE-materialarket för att göra många delar som:

- PTFE packningar

- PTFE bussning

- PTFE foder

- PTFE glidplatta

- PTFE elektriska isoleringsdelar

- PTFE brickor