Are you also curious about the relationship between PTFE and PCTFE? They differ by only one letter, so what are the differences between them? Next, I will explain this from three aspects: definition, similarities, and differences. Just one letter’s difference results in different properties.

Definição

PTFE and PCTFE are both fluoropolymers. PTFE stands for polytetrafluoroethylene, and PCTFE stands for polychlorotrifluoroethylene.

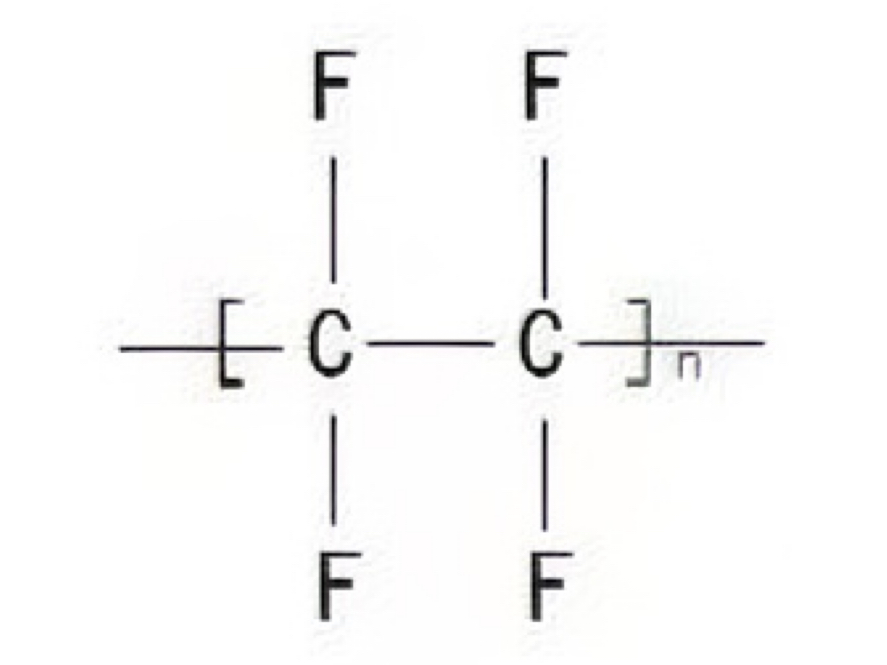

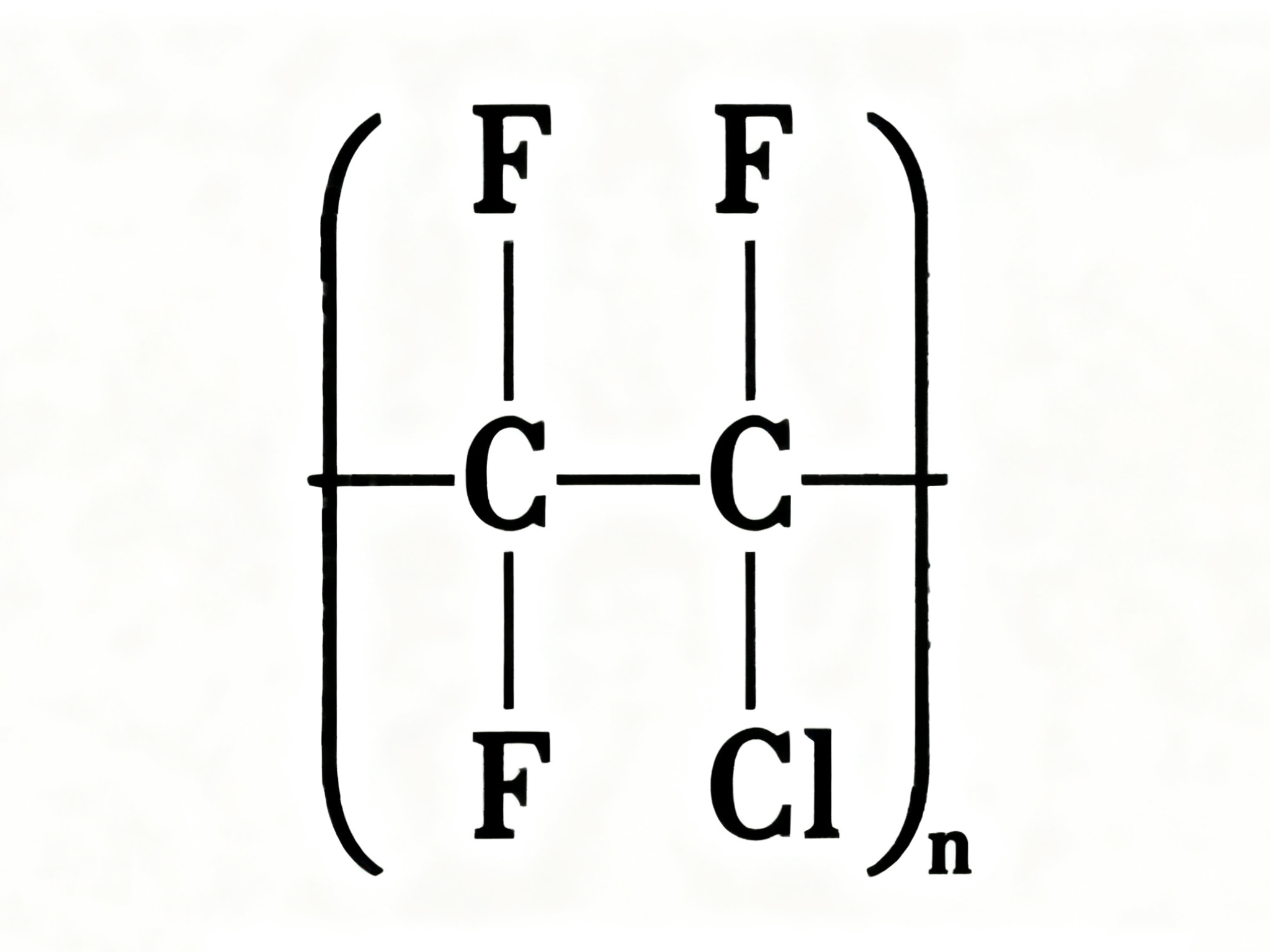

Chemical Structure

The chemical structural formula of PTFE is -[-CF₂-CF₂-]n-, and the chemical structural formula of PCTFE is [-CF(CL)-CF2-]n. The substitution of one fluorine atom with a chlorine atom in PTFE results in significant differences in their properties.

Propriedades

| Performance | PTFE | PCTFE |

| Resistência à tracção | 1500~3000 psi

(20~30 MPa) |

4860~5710 psi

(34~39 MPa) |

| Módulo de Flexão | 72000 psi

(495 MPa) |

2000,000~243,000

(1.4~1.7 GPa) |

| Ponto de fusão | 350℃(621℉) | 210~215℃(410℉) |

| Continuous Operating Temperature Range | -260℃~260℃

(-436~500℉) |

-255~180℃

(-427~356℉) |

| Resistência química | Bom | Slightly inferior to PTFE |

| Coeficiente de atrito | 0.03~0.05 | 0.25~0.35 |

| Cor | White, non-transparent | Milky white, subtransparent |

| Processing | Suitable for injection molding | Not suitable for injection molding |

| Característica | High rigidity | High chemical inertness |

Similarities

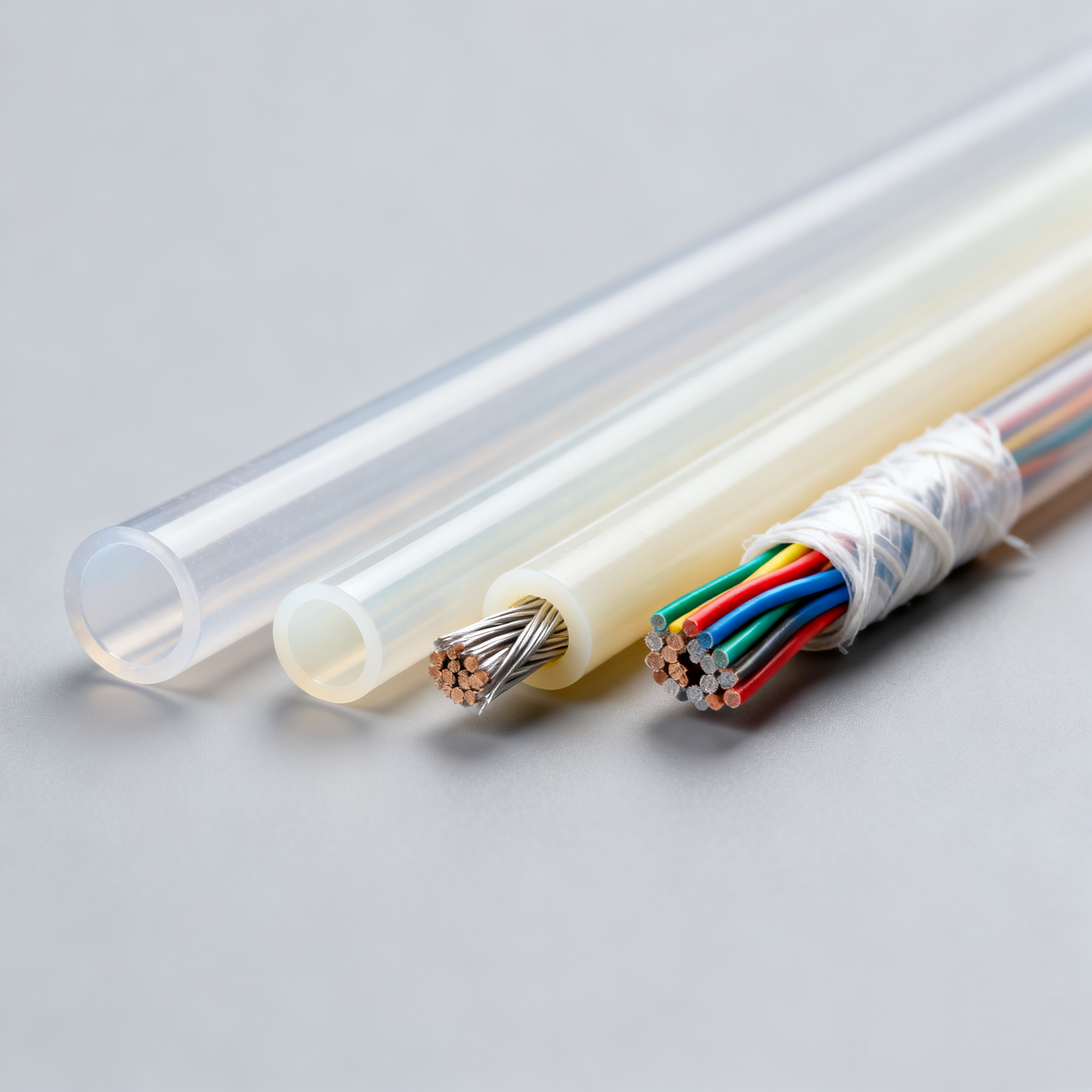

PTFE and PCTFE are both fluoropolymers, essentially plastics. They share similar properties, resisting corrosion from most chemicals, having a wide temperature range, and being resistant to low temperatures, making them suitable for aerospace applications. Both are electrically insulating and are used in high-frequency electronic devices, insulating components, and as insulation layers for wires and cables. They also possess weather resistance, capable of withstanding prolonged exposure to ultraviolet radiation.

Differences

Although PTFE and PCTFE differ by only one letter, some of their properties are altered due to the presence of that single chlorine atom. Below, I will list some of the most significant differences between PCTFE and PTFE.

- The substitution of a fluorine atom with a chlorine atom in PCTFE increases the material’s rigidity, making it harder. PCTFE also exhibits low moisture absorption and extremely low gas permeability, enhancing its mechanical strength and improving its dimensional stability. While PTFE also possesses some rigidity, its hardness is inferior to that of PCTFE, and it is more susceptible to creep under certain stress conditions.

- PCTFE’s radiation resistance is far superior to that of PTFE. PCTFE can maintain stable physical and chemical properties in extremely strong radiation environments and can withstand ionizing radiation, while PTFE has poor radiation resistance and may even disintegrate into powder after prolonged exposure.

- PTFE has extremely high chemical inertness, reacting with almost no chemical substances, and its chemical corrosion resistance far surpasses that of PCTFE. Although PCTFE also exhibits chemical resistance, its tolerance to chlorides and halogenated chemicals is far less than that of PTFE, and it is not suitable for high-temperature and strong oxidizing environments.

- PTFE also has good biocompatibility, is less likely to cause rejection reactions with human blood, and due to its low friction properties, reduces friction with human tissues. It is commonly used in the medical field to manufacture artificial blood vessels or coatings for surgical instruments.

The Price of PCTFE and PTFE

Both PCTFE and PTFE are fluoroplastics, but their prices differ significantly, with PCTFE being much more expensive than PTFE. The best quality imported PTFE from Daikin, Japan, costs approximately 158 yuan/kg, while PCTFE costs between 70 and 900 yuan/kg.This is the price of the raw materials. The price of PCTFE products is 1500 yuan/kg, while the price of PTFE products is approximately 160 yuan/kg.

How to choose the most suitable one?

After reading the above explanation of the differences between PCTFE and PTFE, are you still unsure how to choose between these two materials? Don’t worry, below I will recommend the most suitable material for you based on different properties and their applicable scenarios.

Resistência química

PTFE is known as the “King of Plastics,” primarily due to its chemical inertness and superior overall properties. If you need to use it in strong acid or strong alkali environments, I recommend PTFE. Its chemical resistance far surpasses that of PCTFE, maintaining excellent chemical and physical stability for extended periods in extremely harsh environments such as strong acids and alkalis. While PCTFE also possesses chemical resistance, it can swell or even dissolve when exposed to high temperatures and halogenated organic solvents.

Resistência mecânica

As mentioned above, PCTFE has higher mechanical strength than PTFE, better dimensional stability, and stronger creep resistance. It also maintains good toughness at low temperatures, making it suitable for precision components, low-temperature valves, and valve seats in aerospace applications. PTFE is more brittle, has poorer toughness at low temperatures, and its mechanical strength is not as high as PCTFE.Furthermore, PTFE has a high linear thermal expansion coefficient, which simply means that it expands and contracts more significantly with changes in temperature, resulting in poor dimensional stability.

High Temperature Resistant

The maximum continuous operating temperature for PTFE is 260℃ (500℉), while the maximum continuous operating temperature for PCTFE is 193℃ (380℉). Therefore, if you need to use it in a high-temperature environment, it is best to choose PTFE. Furthermore, the melting point of PTFE is 350℃ (621℉), and the melting point of PCTFE is 215℃ (410℉), making PTFE safer to use. Examples of applications include industrial seals, engine oil seals, and aircraft hydraulic system seals. For everyday use, PTFE can also be used as a non-stick coating for cookware because of its non-stick properties.

Radiation Resistant

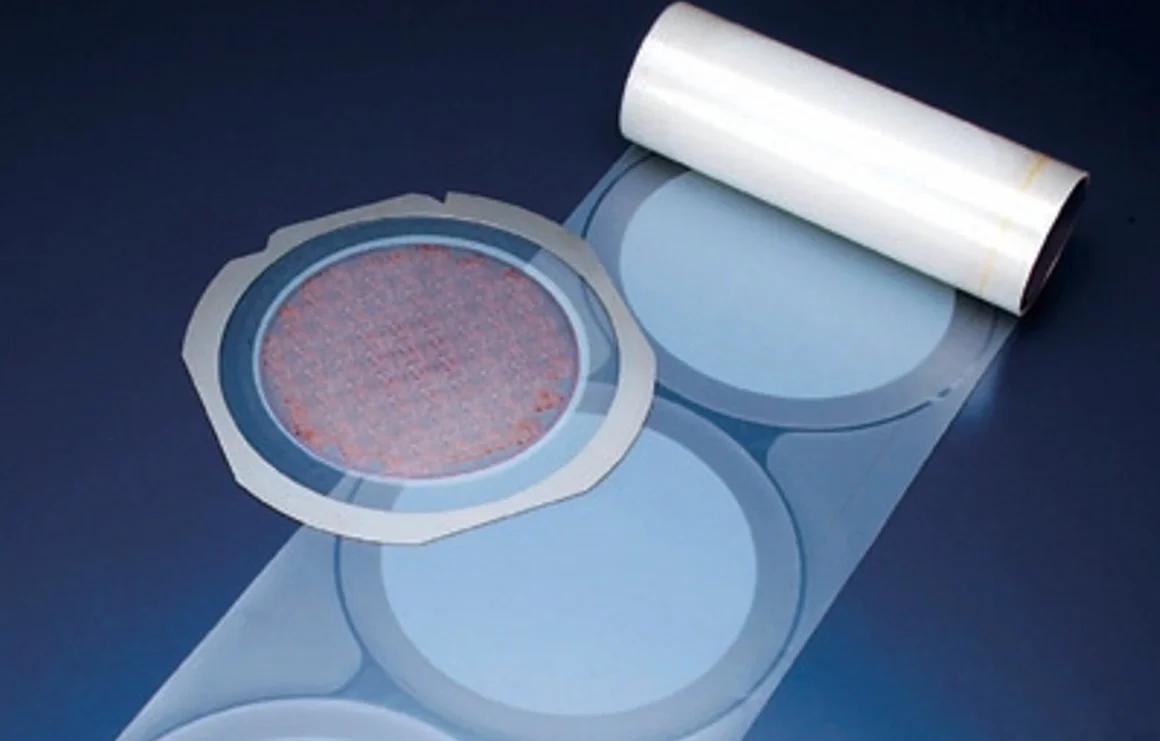

PTFE is easily degraded under strong radiation, but PCTFE has better radiation resistance than PTFE and can be used as an electronic packaging film for spacecraft, effectively shielding against radiation and protecting electronic components; it can also be used as a flexible valve diaphragm in nuclear reactors.In daily life, it can also be used as a covering material for greenhouses.

Resistência ao desgaste

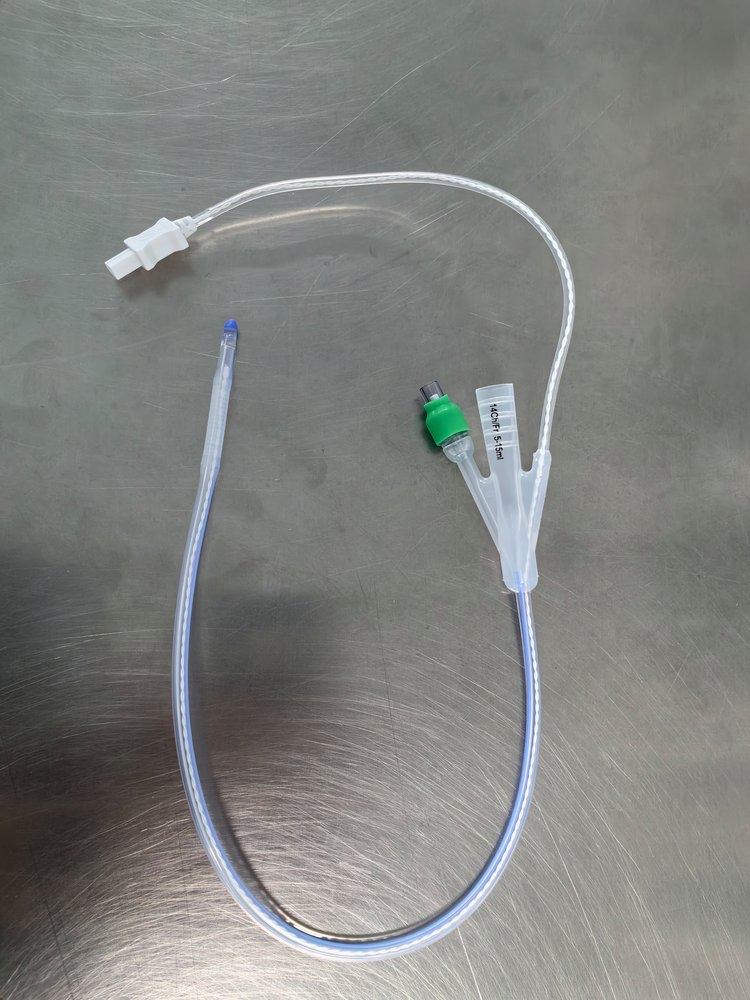

PTFE has a lower coefficient of friction than PCTFE, only 0.03, making it more suitable for manufacturing sliding components such as bearings and bushings, for use in low-friction applications. PTFE is also biocompatible. These two properties combined make PTFE widely used in the medical field. It can be used as a coating for implantable medical devices such as artificial blood vessels, artificial joints, artificial heart valves, or surgical instruments, reducing friction with human organs and leading to faster patient recovery.

Processability

PTFE raw material is highly viscous, making it difficult to process using traditional methods. It requires a process involving cold forming, followed by high-temperature sintering, and finally cooling and shaping; it cannot be injection molded. However, PCTFE is not so complicated; it can be processed using traditional melt processing methods such as injection molding, extrusion molding, or compression molding.

Permeabilidade a gases

PCTFE’s molecular chains contain chlorine atoms, resulting in a more compact molecular arrangement that effectively hinders gas molecule diffusion. Therefore, its gas permeability and outgassing rate are much lower than those of PTFE, making it more suitable for vacuum applications.

Usability

If you are using it for general laboratory research, I recommend PTFE because it is more affordable and has a wide range of applications, making it ideal for research or for manufacturing laboratory equipment. However, if you require transparency, radiation resistance, and mechanical strength, then choose PCTFE. Although it is more expensive, it possesses properties that PTFE lacks.

Conclusão

The above explains the differences between PTFE and PCTFE. If you have any further questions or need to place an order, please contact us. We will respond efficiently within 7 hours. Hansa is a Chinese supplier specializing in PTFE, PCTFE, and other plastic products, with thirty years of manufacturing experience and extensive knowledge of plastic materials. We hope to answer all your questions.

Perguntas frequentes

Is PCTFE the same as PTFE?

Not entirely. Both PCTFE and PTFE are fluoropolymers and plastics, but they have different properties. As mentioned in the text, PCTFE has better mechanical strength and radiation resistance, and is also relatively more expensive.

What is the other name for PCTFE?

PCTFE stands for polychlorotrifluoroethylene, also known as chlorotrifluoroethylene homopolymer, which is an accurate description from a chemical perspective. It also has a commercial brand name, similar to Teflon (which is PTFE). The commercial brand name for PCTFE is Kel-F, which was once widely known.

Is PCTFE a thermoplastic?

Yes, PCTFE is a thermoplastic. When PCTFE is heated to above its melting point of 220°C, it melts and becomes a fluid, allowing it to be processed using traditional melt processing methods such as injection molding and extrusion. It can be processed into any complex shape and is recyclable.

PCTFE Density

The density of PCTFE is 2.10-2.17 g/cm³, and the density of PTFE is 2.14-2.20 g/cm³.