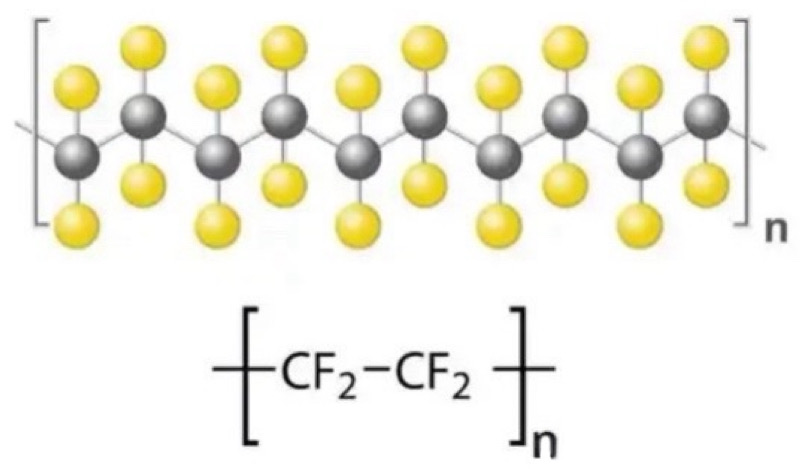

What is PTFE?

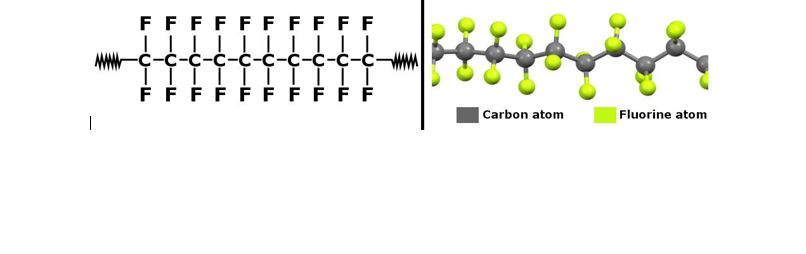

Chemical formula and structure (C₂F₄)n

PTFE stands for Polytetrafluoroethylene. It is a synthetic plastic made by combining many units of a chemical called tetrafluoroethylene. Its chemical formula is (C₂F₄)n. People often call it “Teflon.” Because it has very good physical and chemical properties, it is widely used in many different industries.

The history of PTFE

- In 1938, a chemist from DuPont, Roy Plunkett, accidentally discovered PTFE while researching.

- In 1940, due to its strong corrosion resistance, PTFE was used to make seals and linings for processing hexafluoride, contributing greatly to atomic bomb development and research.

- In 1945, “Teflon” became a registered trademark, owned by DuPont.

- In 1954, the properties of PTFE were further explored, and its applications expanded. A French engineer applied PTFE coating to cookware, inventing the world’s first non-stick frying pan. Afterward, PTFE was widely used in industries like healthcare, aerospace, and construction.

- From 1980 to 2000, PTFE was continuously developed, and ePTFE (expanded PTFE) was created through a stretching process, resulting in a porous structure.

- In recent years, PTFE has been used in high-tech fields like high-frequency communications and 5G infrastructure.

How is PTFE made?

PTFE is made by polymerizing tetrafluoroethylene (TFE) monomers. The TFE monomer is produced either by heating chloroform to break it down or by reacting zinc with chlorodifluoromethane at high temperatures. Then, using initiators like peroxides, the TFE monomers undergo polymerization under high pressure and low temperature conditions, forming PTFE as a white powder.

Types of PTFE

There are many ways to classify PTFE. I will roughly divide it into three types, starting with the most basic classification:

Based on the physical state and properties of PTFE, it can be classified into three types: Suspension Polymerized PTFE, Dispersion Polymerized PTFE, and Modified PTFE.

- Suspension Polymerized PTFE: This type looks like small particles and has high purity. It is usually processed into large sheets through molding and sintering.

2. Dispersion Polymerized PTFE: This type appears as fine powder. It is used to make thin-walled pipes, wire insulation, and can also be processed into films.

3. 改質PTFE: As the name suggests, this type has improved properties. By adding materials like glass fiber, carbon fiber, or graphite into pure PTFE, its wear resistance, creep resistance, and other features are enhanced, making it suitable for more applications.

Based on the final physical form of PTFE products, they can be classified into the following types

1. PTFEシート: This includes molded sheets, machined sheets, and sintered sheets. Molded sheets are usually thicker and harder, while machined sheets are thinner and often rolled up during storage and transport. Sintered sheets come in single-sided and double-sided sintered versions and are often used with PFA. These products are highly resistant to chemicals and have low friction, so they are commonly used to make corrosion-resistant containers, gaskets, guide rails, etc.

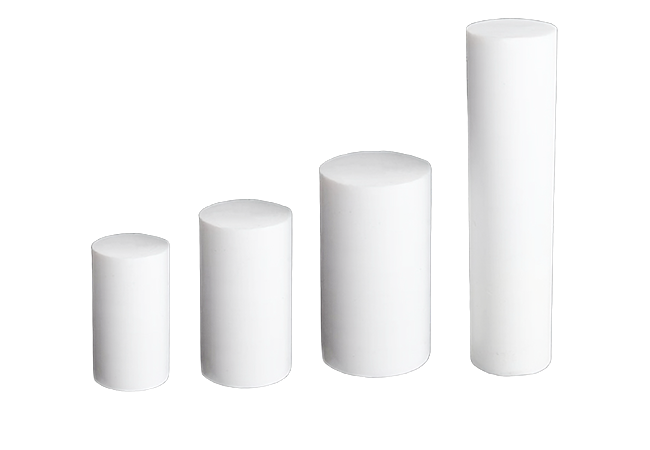

2. PTFEロッド: This includes molded rods, extruded rods, and ram-extruded rods. Different production processes lead to different names and appearances. Molded rods are usually short and thick, extruded rods are longer and thinner, and ram-extruded rods look similar but have lower density and stronger toughness.

3. PTFE Tubes: Like rods, PTFE pipes can be molded or extruded. There are also PTFE flexible hoses, which are thinner, longer, and more flexible. The smallest inner diameter can be as small as 0.06 mm, known as capillary tubes, but they are also more expensive.

4. PTFE Films: These are thin, lightweight, and heat-resistant plastic films. They are typically used for high-frequency insulation, non-stick coatings, and filtration materials. In everyday life, the surface of non-stick pans is made from PTFE film.

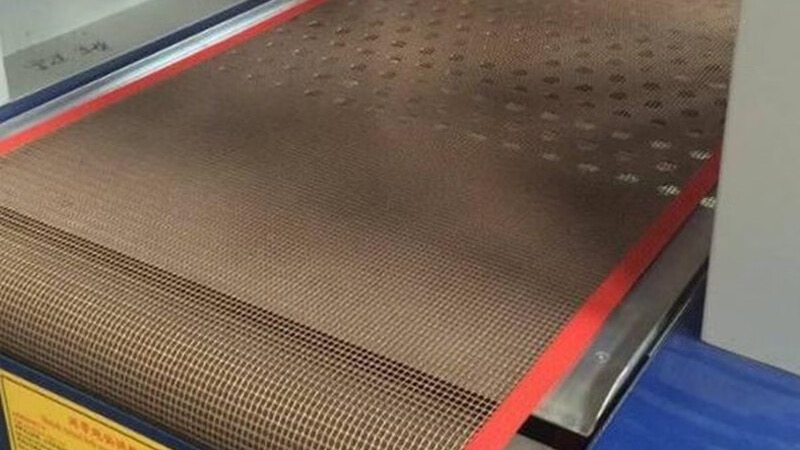

5. PTFE High-Temperature Fabric: Made from high-quality fiberglass cloth, woven using plain or twill weave methods, and then coated with PTFE resin. It can withstand extreme temperatures ranging from -196°C to 350°C and has non-stick properties.

6. PTFEパッキング: Made from solid woven pure PTFE material, it has a smooth surface, relatively low friction, and high toughness, making it adaptable to sealing various shapes and sizes.

7. PTFE Ball Rings: These cylindrical rings have several hollow sections on the surface, with the top and bottom offset. The outer wall of one half extends inward, intersecting at the center of the ring. This unique structure allows the inner surface to be fully utilized, improving liquid distribution and increasing production efficiency. They have non-stick properties and are less likely to clog.

8. PTFE Machined Parts: Customized according to drawings, these are PTFE products made in various shapes.

Based on different properties, PTFE can also be classified into three types.

- 純PTFE: This is the standard, unmodified PTFE, without any improvements or optimizations. It has poor creep resistance.

- Reinforced PTFE: This type has its physical properties altered by adding fillers. It enhances the hardness of PTFE and reduces its cold flow characteristics.

- Soluble PTFE: Also known as PFA, this type has a modified molecular structure, making it melt-processable. It can be molded into various complex shapes through injection molding.

Common grades of PTFE

Inorganic Non-metallic Fillers

| Filler | Improvements | 制限事項 | アプリケーション |

| Glass fiber-filled PTFE |

|

|

|

| Carbon Fiber-filled PTFE |

|

|

|

| グラファイト充填PTFE |

|

May reduce mechanical strength |

|

| Mineral-filled PTFE |

|

High content may cause brittleness |

|

Metal and Alloy Fillers

| Filler | Improvements | 制限事項 | アプリケーション |

| Bronze Powder-filled PTFE |

|

Prone to oxidation |

|

| Aluminum Powder-filled PTFE | Improved lubrication | Not environmentally friendly | Often replaced by tin powder |

Solid Lubricant Fillers

| Filler | Improvements | 制限事項 | アプリケーション |

| Molybdenum Disulfide-filled PTFE | Improved self-lubrication |

|

|

| PTFE Wax-filled | Enhanced surface lubrication | —— | Food-grade applications |

| Silicon Nitride-filled PTFE |

|

—— | High-temperature environments |

Composite-filled PTFE

| Filler | Improvements | 制限事項 | アプリケーション |

| Glass Fiber+Graphite | Combines wear resistance and lubrication | —— | General sealing applications |

| Carbon Fiber+Bronze Powder |

|

—— |

|

| Molybdenum Disulfide+Carbon Fiber |

|

—— | Precision transmission components |

Why is it used?

PTFE was discovered and applied because of its unique performance advantages. Its properties are not just one single feature, but a combination of many extreme characteristics. Compared to other materials, PTFE has the strongest overall performance.

-

耐薬品性: PTFE is resistant to almost all chemicals, including strong acids, strong bases, organic solvents, and corrosive gases. This makes it useful in laboratories, the chemical industry, and the pharmaceutical industry.

-

熱安定性: PTFE maintains its physical and chemical properties even in extreme conditions. Its typical working temperature range is from -200°C to 260°C, and it can withstand even higher temperatures, up to 300°C for short periods. This makes it ideal for aerospace seals, cable insulation, and coatings for high-temperature industrial furnaces.

-

Non-stick Properties: PTFE does not stick to almost any substance and is both water- and oil-resistant. It is used in non-stick cookware, baking pans, food processing conveyor belts, and as a lining in molds.

-

Low Friction: PTFE has an extremely low coefficient of friction (around 0.04), which is the lowest of any solid material. This allows it to remain smooth without lubrication. It is used in making bearings, gears, and slides in low-friction machinery.

-

電気絶縁: PTFE is an excellent electrical insulator, with its insulating properties unaffected by temperature, humidity, or frequency. It is used in cable insulation, transformers, and insulating gaskets for capacitors.

-

Non-toxic and Safe for Humans: PTFE is non-toxic and harmless to the human body, making it suitable for medical applications like artificial blood vessels and implantable medical devices.

What are the disadvantages of PTFE?

-

Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

-

Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

-

Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

-

Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

Can PTFE be recycled?

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

Issues with PTFE Recycling:

- High Heat Stability: PTFE has a high melting point of 327°C and begins to decompose above 260°C, releasing toxic gases like hydrogen fluoride.

- Impurities in Waste: PTFE waste often contains impurities such as adhesives, metals from industrial components, or lab residues, which can render recycled PTFE unusable.

- Low Quality of Recycled PTFE: The quality of recycled PTFE is often lower, making it less competitive in terms of price.

- Separation Issues: Consumers and businesses rarely separate PTFE from other waste, and recyclers struggle to source enough material.

Some manufacturers have set up internal recycling projects, where they recycle their own production waste into lower-grade PTFE composites. In regions like Europe and North America, specialized recyclers collect PTFE waste from sectors like aerospace and healthcare, processing it into recycled pellets for use in non-critical applications.

結論:

While PTFE recycling is not impossible, large-scale implementation is currently challenging. To promote PTFE as a renewable resource, it requires coordinated efforts. Research teams could focus on developing low-energy pyrolysis methods, such as using catalysts to lower the required temperature. Regulatory bodies can encourage companies to reduce PTFE waste and design products that are easier to recycle. Consumers can play their part by separating PTFE waste and placing it in designated recycling bins. With increased raw material supply, large-scale PTFE recycling could become more feasible.

4 Typical applications

PTFE (Polytetrafluoroethylene) has many uses and subtly changes our lives. Below, I will introduce four key areas where PTFE is commonly applied:

-

Everyday Life

Nowadays, everyone uses non-stick pans for cooking. Traditional iron pans are hard to control for beginners—if the heat is too high, food sticks and burns. Non-stick pans with a PTFE coating solve this problem. PTFE’s stable molecular structure and low surface tension prevent water and oil from sticking, causing them to roll off without leaving residue. PTFE is chemically stable, resistant to acids and bases, and won’t react with food, preventing sticking. Once the coating is cured, it creates a smooth surface, reducing friction between the food and the pan. Besides non-stick pans, PTFE is used in ovens and baking molds for similar reasons, making cooking easier.

PTFE is also used in everyday items like waterproof fabrics in jackets and tents, which help keep us dry. The sole of our irons is coated with PTFE, reducing friction (with a coefficient of 0.04) and protecting clothes from damage.

-

Industrial Manufacturing

In industry, many chemical reactions require containers that won’t react with substances. PTFE coatings are used as liners for reactors, storage tanks, and pipes because PTFE is resistant to nearly all chemicals. This extends the equipment’s lifespan and reduces maintenance costs. For example, seals in valves (like O-rings and gaskets) are often made from PTFE due to its resistance to extreme temperatures and high pressure, maintaining performance in tough conditions.

PTFE’s low friction properties are also useful in mechanical parts like bearings, sliders, and gears, reducing wear and tear. In textile machines, PTFE helps reduce thread breakage, and in precision instruments, it improves transmission accuracy. Since PTFE is self-lubricating, it doesn’t need regular oiling, unlike metal parts, which also helps prevent environmental pollution.

-

Healthcare

With ongoing technological advancements, the medical field has greatly benefited from PTFE. Many devices, such as artificial blood vessels and heart valves, use PTFE. Artificial blood vessels must mimic the function of real arteries, needing to resist blood clots, be flexible, and withstand body fluids. PTFE’s chemical stability, resistance to acids and bodily fluids, and smooth surface reduce the risk of blood clot formation and help maintain vessel flow. Its microporous structure also allows cells to grow into it, improving integration with surrounding tissue and lowering rejection risks.

Heart valves, which endure constant pressure and deformation, rely on PTFE’s toughness to avoid breaking over time. PTFE is also used as a coating for orthopedic implants, reducing friction with tissues and lowering inflammation risks.

Beyond implants, PTFE is found in medical supplies like syringe pistons and IV tubes, where its low friction reduces resistance and minimizes damage to blood vessels. In laboratories, PTFE’s resistance to chemicals ensures accuracy in experiments involving culture dishes or transplant tubes.

-

High-Tech Industries

PTFE is also found in high-tech fields like aerospace and electronics. In space exploration, spacecraft must withstand extreme temperature fluctuations when re-entering the atmosphere. PTFE’s melting point of 327°C and temperature range of -200°C to 260°C make it an ideal material for thermal insulation in spacecraft. Additionally, its corrosion resistance makes PTFE perfect for sealing engine components, preventing damage from fluctuating temperatures and corrosive gases produced during fuel combustion.

In electronics and nuclear energy, PTFE’s radiation and corrosion resistance help it maintain stability in high-risk environments. It’s often used as a shielding layer in high-frequency communication cables and structural components in nuclear reactors.

5 Typical processing methods

Due to the extremely high melt viscosity of PTFE, traditional thermoplastic molding methods like injection molding or blow molding cannot be used. Therefore, special processes, such as “cold forming” and “high-temperature sintering,” are required. Different processing methods result in different properties for PTFE products, affecting their density, mechanical strength, dimensional accuracy, and more. Below are five typical processing methods:

-

Mold Compression Molding

PTFE powder is compressed at room temperature into a preform, and high-temperature sintering causes the particles to fuse together, followed by cooling and setting. In short, the process first densifies the material physically (cold pressing), then bonds the particles chemically/physically (sintering), and finally stabilizes the shape (slow cooling), making it suitable for PTFE’s characteristic of “not flowing at high temperatures but compacting at room temperature.”

-

Cold Pressing:PTFE powder particles are tightly packed under mechanical pressure at room temperature, pushing out air between particles to form a preform with a certain strength.

-

焼結:High temperature melts and diffuses the PTFE particles in the preform, ultimately forming a continuous, solid structure.

-

Cooling:Slow cooling allows the molten PTFE to recrystallize, avoiding internal stress that could lead to cracking.

This method is suitable for simple, thick-walled products such as sheets, rods, gaskets, and discs. It’s simple, low-cost, and ideal for small batch production. The size of the final product is limited by the mold.

-

-

押出成形

Unlike mold compression, this method requires the addition of an extrusion aid. PTFE paste with an extrusion aid is pressured by a plunger to continuously flow through a mold at room temperature, forming a continuous shape. The product is then degreased and sintered. Degreasing removes the extrusion aid by heating to a temperature of 60–120°C, where it evaporates slowly.

This method is suitable for producing long, thin-walled products like pipes, cable insulation, and fine rods. It is more efficient than mold compression but depends on the mold shape.

-

含浸成形

Porous base materials, such as fiber fabrics or metal meshes, are immersed in a PTFE dispersion solution. The PTFE then adsorbs, dries, and sinters, forming a continuous coating or composite structure on the surface or inside the pores of the base material. The key idea here is using the flowability of the PTFE dispersion to penetrate, attach, and solidify, bonding the PTFE to the substrate.

This method is used for applications like corrosion-resistant filter fabrics, high-temperature conveyor belts, and composite sealing materials. It gives the base material PTFE’s corrosion resistance and low friction, but controlling the uniformity of the coating thickness can be challenging.

-

Stretch Forming

After sintering, PTFE preforms are plastically deformed by unidirectional or bidirectional stretching, forming a porous network structure called e-PTFE. This process takes advantage of PTFE’s ability to stretch at specific temperatures, breaking its tight crystalline structure with external force.

This method is commonly used for products like artificial blood vessels, breathable membranes, and sealing tapes. It allows control over porosity and mechanical properties, but process parameters, such as stretching speed and temperature, greatly impact the final product’s performance.

-

機械加工

This is a physical forming method that uses mechanical processes to shape sintered PTFE preforms, such as turning, milling, and drilling. It is typically used to produce precision seals, custom gaskets, and bearings. While it allows for complex shapes and high precision, material utilization is very low, making it suitable only for small batch customization.

What’s the difference between PTFE and Teflon?

Is PTFE the same as Teflon? What’s the difference between them? Have these questions been confusing you? Don’t worry, I’ll explain it to you now.

Let’s start with their basic definitions. PTFE stands for Polytetrafluoroethylene, which is a synthetic fluoropolymer. Teflon is the brand name for PTFE registered by the company DuPont. In simple terms, PTFE is the material, while Teflon is the brand.

Their product ranges are also different.PTFE is a general term for the material itself, Polytetrafluoroethylene. While Teflon originally referred to PTFE, over time the Teflon brand has expanded to include other fluoropolymers, like PFA, FEP, and more.

Many people think these are two different materials, but they’re not. Teflon was originally just a brand for PTFE, but now Teflon has expanded its range to include more products.

So when do we use PTFE and when do we use Teflon? It’s simple. When you’re talking about the material itself, you use PTFE. When referring to products from the Teflon brand, you use Teflon. For example, if a non-stick pan has the Teflon logo, it means it’s a product of the Teflon brand. If the product specification says PTFE, it means the material used is PTFE.

Is PTFE Harmful?

Normal Conditions

In daily life, when cooking—like stir-frying or frying eggs—the temperature is typically between 150°C and 200°C. Frying oil usually reaches 200°C to 230°C, all of which are below the 260°C decomposition temperature of PTFE. Only during dry heating, when there’s nothing in the pan, can the temperature rise above 260°C quickly.

Additionally, PTFE has been certified by both the FDA and EFSA, meaning that it is safe to use with food under normal conditions.

Modern PTFE products often have a reinforced surface, making them even safer and not harmful to human health.

High Temperatures

When heated above 260°C, PTFE begins to slowly break down. If the temperature exceeds 350°C, the breakdown speeds up, releasing harmful gases like hydrogen fluoride and perfluoroisobutene. Breathing in high concentrations of these gases in a short period can cause “polymer fume fever,” with symptoms like headaches, coughing, and chest tightness.

Common Misunderstanding

People often confuse PTFE with PFOA, but they are not the same. In the past, PFOA was used as a processing aid in PTFE production. However, since 2010, its use has been banned in many countries worldwide.

Why should you choose PTFE?

Since PTFE was discovered, it has been widely used around the world. Its unique properties have created different user groups. Which category do you fall into? Why choose PTFE? I can provide you with simple and scientific guidance.

For Businesses:

In the industrial field, PTFE, with its extremely low friction coefficient of 0.04, helps machinery operate more efficiently, improving overall performance. It can save businesses time and money. Thanks to PTFE’s chemical resistance to acids and bases, machinery lifespan is extended, and maintenance costs are reduced. Its high and low-temperature resistance (-200°C to 260°C) ensures stable production, shortening time costs. The low friction also reduces wear on machine parts, cutting down energy consumption.

In food production, PTFE is commonly used for conveyor belts, mold linings, and mixing paddle coatings. It ensures safety with FDA certification and its non-stick properties reduce food residue, preventing contamination, making cleaning easier, and boosting production efficiency.

In the medical field, PTFE is used in the production of medical devices like intravenous tubes, catheters, artificial blood vessels, and surgical sutures. It is safe and non-toxic, and its chemical inertness, biocompatibility, and low friction ensure it doesn’t react with human tissues, avoiding rejection.

For Manufacturers:

PTFE is used to make non-stick cookware, electric iron soles, baking tray coatings, etc., improving non-stick performance and increasing product market competitiveness.

For products like tent coatings, protective clothing, raincoats, and jackets, PTFE provides water resistance, breathability, and durability, enhancing the product’s value.

For Consumers:

When using non-stick pans, PTFE ensures that food doesn’t stick, making it easier to clean, and allows for less oil usage, promoting healthier cooking. PTFE’s excellent temperature resistance makes it suitable for various types of stoves, whether gas or induction cookers.

For outdoor travelers, PTFE-coated products help keep you cool by reducing heat buildup and can even protect against wind and snow. It’s especially friendly to hikers.

For patients, PTFE’s low friction helps reduce irritation with other organs, lowering the risk of infection, and improving treatment efficiency and comfort.

よくある質問:

PTFE vs similar materials

| 耐薬品性 | 耐熱性 | 機械的特性 | 熱特性 | 耐摩耗性 | 電気的特性 | Impact Resistance | 摩擦 | Moisture | |

| PTFE | almost all | -200~260℃ | Low strength and poor rigidity | Better | Medium, self-lubricating | Good, arc resistance | Poor, high brittleness | 良い | Bad |

| PE | Acid and alkali resistant Not resistant to organic solvents | -60~60℃ | Low strength, easy to deform | 貧しい | 貧しい | Better | Medium | 良い | Bad |

| PET | Water and oil resistant

Not resistant to strong acids and alkalis |

-40~120℃ | Medium strength, good rigidity | Medium | Medium | Medium | 貧しい | Better | 貧しい |

| PC | Water and oil resistant

Not resistant to organic solvents |

-40~120℃ | High strength and good rigidity | Medium | 貧しい | Good, corona resistant | Better | Better | 貧しい |

| ナイロン | Oil and grease resistant

Not resistant to strong acids and alkalis |

-40~120℃ | High strength and good toughness | 貧しい | Better, self-lubricating | Medium | Better | Bad | 良い |

| HDPE | Better than PE | -60~100℃ | Better than PE | Poor, better than PE | Poor, better than PE | Better | Better than PE | 良い | Bad |

| POM | Resistant to oil and grease Not resistant to strong acids and alkalis |

-40~100℃ | High strength and good rigidity | 貧しい | Better | Medium | 貧しい | Better | 貧しい |

| ピーク | Resistant to most chemicals | -269~250℃ | Excellent strength, rigidity and toughness | Good, flame retardant | Better | Good, radiation resistant | Better | 良い | Bad |

What are the raw materials for PTFE parts?

The main raw material is polytetrafluoroethylene (PTFE) resin, which typically exists in powder form. Sometimes, small amounts of auxiliary materials, such as lubricants, may be added.

How to choose the right PTFE manufacturer?

Do you have a long-term, reliable PTFE supplier? If you do, here are a few ways to check if they’re of high quality. If not, this article will teach you how to choose the right, high-quality PTFE supplier.

-

Product Range

The variety of products a supplier offers determines whether they can meet your diverse needs. If a supplier only offers a narrow selection, your options are limited. Even if their quality and price are good, you’ll need to find another supplier when your needs change, which can be inefficient in terms of time. However, if the supplier has a comprehensive range of products, you can satisfy most of your needs from them, making it a one-stop shop and saving time in the long run.

-

品質保証

Quality is essential. The basics include whether the supplier has ISO international certification and FDA approval. Does the supplier manage the entire supply chain, from raw materials to finished products? Key indicators include long-term relationships with raw material suppliers, advanced molding processes, digital control over critical procedures, and CNC machining for custom parts. Additionally, does the supplier have a robust testing process for materials, production, and final products? These factors show their professionalism.

-

価格

Price is also an important factor. Prices that are too low or too high should raise red flags. A reasonable price range is best. If the price is significantly different from what you expect, consider:

- Too low: Is the product cutting corners or made with cheaper materials?

- Too high: Is the supplier trying to overcharge, not offering a fair deal? However, higher prices can sometimes be justified if the quality is better and the product is more durable in the long run.

-

Supplier Experience & Reputation

A supplier’s experience and reputation are crucial for a long-term partnership. Before working with you, does the supplier ask about your product’s purpose and usage scenarios, and offer professional advice? You can check their reputation through online reviews, industry forums, or by conducting a site visit to assess if they’re worth a long-term collaboration.

-

Customer Service

Don’t overlook customer service. After making an inquiry or sending an email, does the supplier respond promptly and professionally? Are their suggestions helpful? How you feel about their customer service can impact your overall experience.

-

Delivery Time & Risk Management

To avoid risks in the partnership, consider the supplier’s production capacity and their ability to handle large orders and deliver on time. A reliable supplier should also have contingency plans in place for unexpected situations.

-

Sustainability

Lastly, consider suppliers that are committed to sustainability. Suppliers with recycling and repurposing plans show they are responsible and future-conscious.

PTFE alternative

Since PTFE was discovered, people have often questioned whether it is toxic and harmful to human health. In the past, PFOA was used as a processing aid when producing PTFE. However, in 2023, the World Health Organization classified PFOA as a Group 1 carcinogen, and it has now been banned.

The situation depends on the specific case. Although PTFE has excellent overall properties, it may lack the necessary specific features for certain high-performance applications. What does this mean? For example, in extremely high-temperature environments, exceeding PTFE’s temperature limit of 260°C, toxic gases may be released. In such cases, a different material, like PI, which can withstand temperatures of 260–300°C, would be a better option.

Here are some polymer materials that can replace PTFE in certain applications, with properties that are equal to or even better than PTFE in specific areas:

- PFA: Used to replace PTFE products that require complex forming. Its biggest advantage is that it can be melt-processed.

- FEP: Less expensive than PTFE and PFA.

- PVDF: Has higher mechanical strength and toughness than PTFE and is cheaper. However, its temperature range is limited to -40°C to 150°C.

- PPS: Replaces PTFE parts that require structural support. It has higher hardness and stiffness than PTFE, but a slightly higher friction coefficient, typically around 0.3–0.5.

- ピーク: Used in PTFE applications that require high strength and biological safety. It is wear-resistant, chemically resistant, has extremely high mechanical strength (impact-resistant and fatigue-resistant), and is also biocompatible.

- UHMWPE: Used to replace PTFE parts that require high wear resistance at room temperature. It has a lower friction coefficient, excellent wear resistance, and retains elasticity even at low temperatures. It is also much cheaper than PTFE. However, its high-temperature resistance is poor, not exceeding 80°C, and it has limited chemical resistance, especially to strong oxidizing agents.

PTFE price

The price of PTFE is influenced by many factors, and it varies across different regions.

Raw Material Impact:

PTFE is made by polymerizing TFE monomers, and TFE’s raw material is HF (hydrofluoric acid), which relies on fluorite (fluorspar). China holds the largest global reserves of fluorite, accounting for about 60%. Since 2024, in response to the green development strategy, the Chinese government has implemented stricter controls on the fluorochemical industry and limited the mining of fluorite, which has led to an increase in PTFE costs.

Supply Side:

While the supply of regular raw materials is almost saturated, there is still a lag in the supply of high-end materials. This has caused a “price drop for regular materials and price premiums for high-end materials” phenomenon. On the demand side, emerging industries such as new energy, semiconductors, and medical implants, all of which require PTFE, have caused global PTFE demand to increase by 8% in 2024. However, traditional sectors, like non-stick cookware, have seen a drop in demand due to “fluorine-free substitutes.”

Government Policy Impact:

According to the EU’s “POPs” regulation, there is a stronger focus on controlling fluorine pollution, limiting the emission of fluorides. Many companies have been required to install exhaust treatment systems, which has increased production costs, leading to higher PTFE prices.

Invisible Costs:

There are also some hidden costs that are not immediately obvious. Energy consumption during PTFE production accounts for 10-15% of total costs, and international shipping fees have increased by 25% compared to 2023, which further drives up PTFE prices.

Regional Differences:

- 中国: As the world’s largest producer, prices are influenced by fluorite supply. In Q1 2025, the price of PTFE was around 32 yuan/kg, but it increased to 40 yuan/kg in Q2.

- Europe & America: These regions are heavily reliant on imports, and prices are affected by tariffs and logistics, causing them to rise to about $60–70 per kg.

- Southeast Asia: Typically focused on lower-end products, PTFE prices in this region range from 38 to 42 yuan/kg.

Procurement Recommendations:

- Choose high-quality, long-term suppliers: Building a stable partnership can help secure low-cost, high-quality products and reduce procurement risks.

- Monitor raw material price trends: Stock up during price dips to take advantage of lower costs.

- Use alternative materials: Consider using other materials with similar properties to PTFE when possible.