ハンザのPTFEシート

- 用途:様々な媒体で使用するシール材および潤滑剤、ならびに様々な周波数で使用する電気絶縁材。コンデンサ媒体、電線絶縁材、電気計装機器絶縁材。

- 化学処理装置、パイプライン、バルブ、反応器用ガスケット/ライナー

- フランジシーリングシステム、高温高圧(HTHP)シーリングガスケット

- 耐摩耗部品、リニアガイドおよびベアリング用低摩擦摩耗パッド

- 耐腐食ライニング、酸タンク/電気めっき槽ライナー(例:耐硫酸/耐硝酸)

HANSA PTFEシート

ハンザは、様々な種類のPTFEシートやフィルムをご提供いたします。ロール状のPTFEシート、強化PTFEシート、あるいはサイズカットなど、お客様のご要望に合わせて高品質な素材を常にご提供いたします。サイズ、色、種類、厚さなど、どんなご要望でもお気軽にお問い合わせください。無料サンプルで品質をご確認ください。

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

PTFEシートには様々な種類があり、1.製造工程別、2.充填剤/改質別、3.色別、4.用途別、5.仕様別、6.特殊タイプ(多孔質PTFEシート(一般に「延伸PTFEボード」と呼ばれる)を含む)に分類できます。

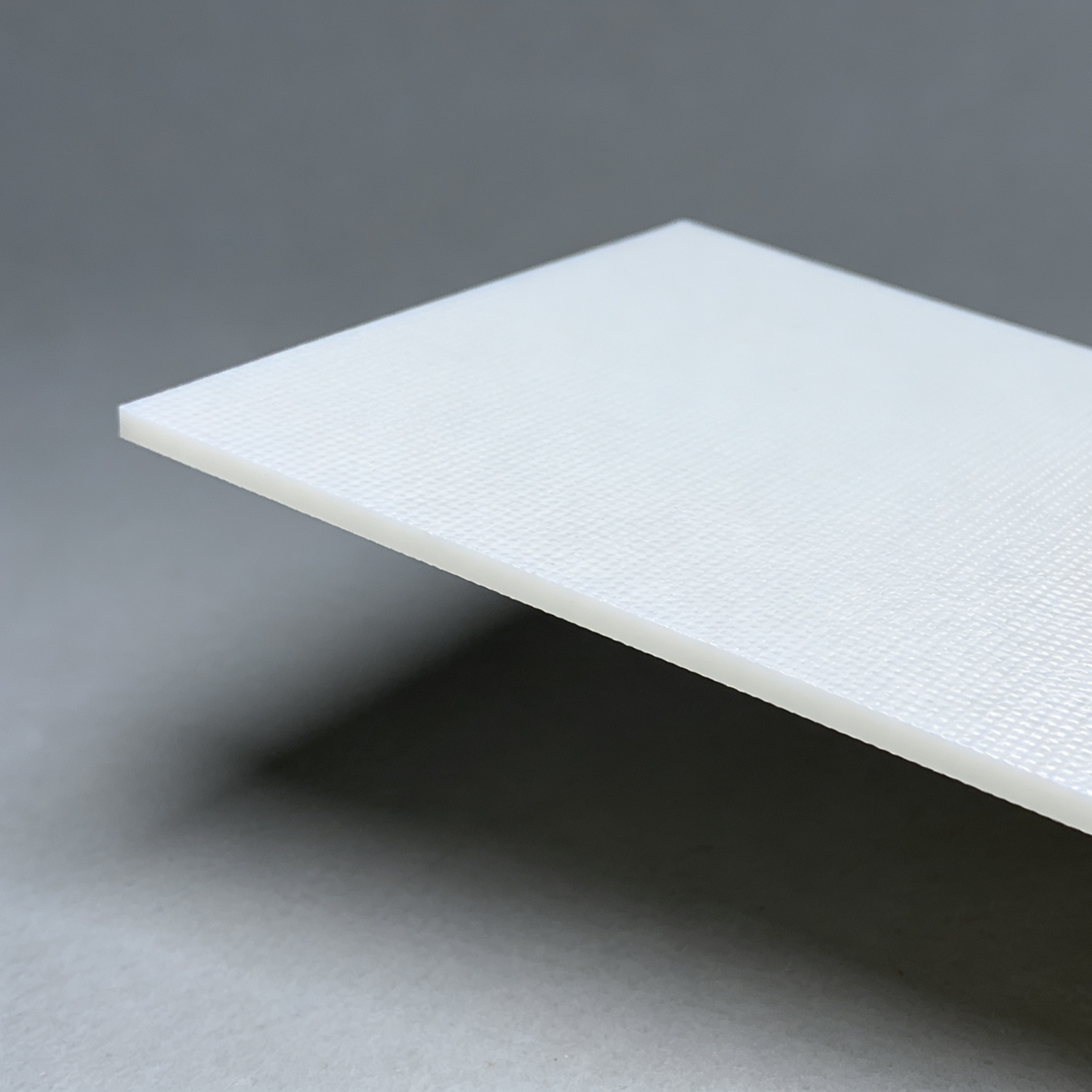

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

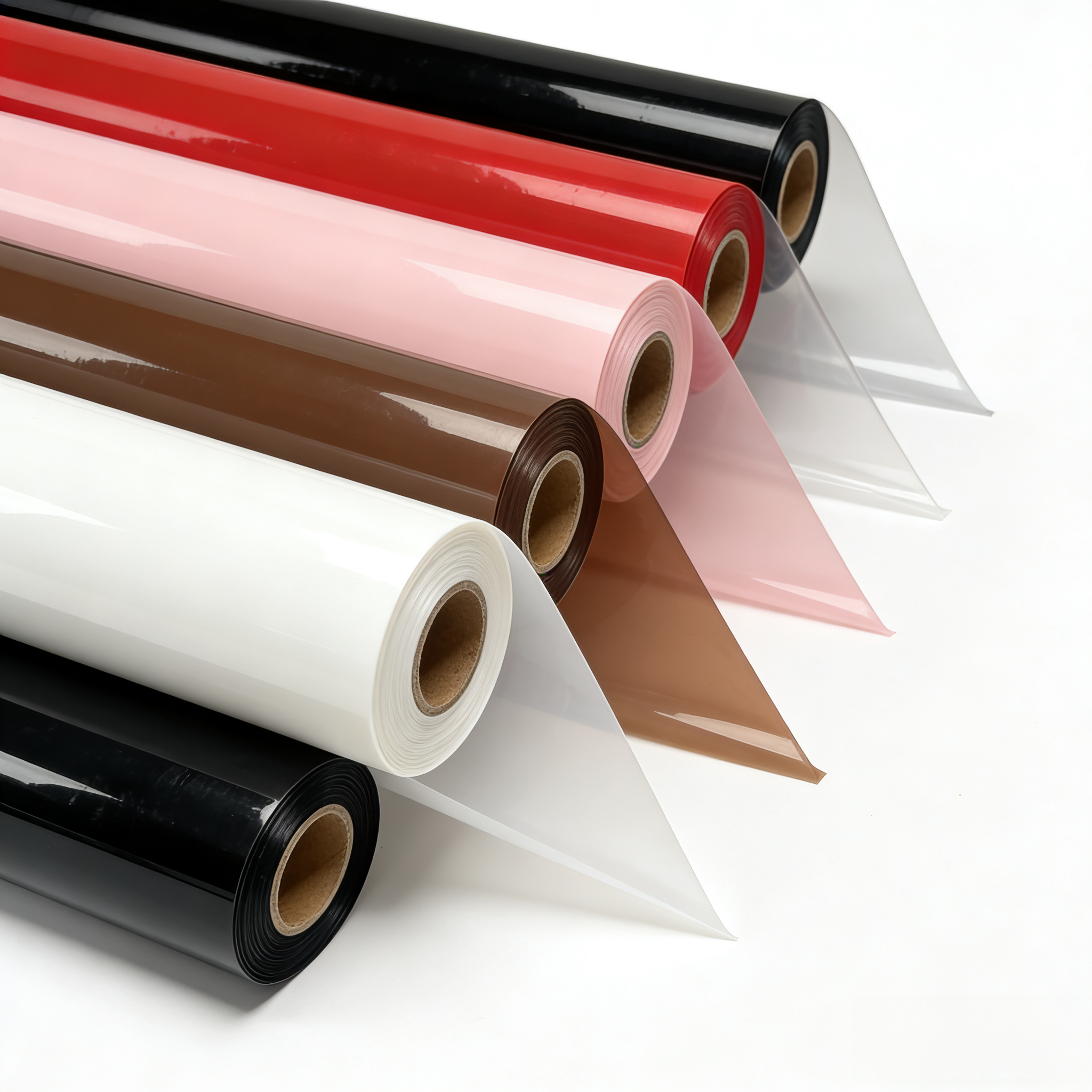

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

PTFEシートの主な特徴

常温では良好な圧縮性およびクリープ耐性を示しますが、高温下では軟化することがあり、低応力の用途に適しています。

摩擦係数 (COF) は 0.04 と低く、自己潤滑性を備えた滑らかな表面により外部潤滑剤が不要です。

腐食耐性があり、腐食性物質やほとんどの化学媒体(pH 0 ~ 14)に耐えることができます。

動作範囲は、持続的なサービスでは -200°C ~ +260°C で、短期的な露出許容範囲は 300°C までです。

PTFEシートの用途

産業:パイプやタンク用のシール、ガスケット、ベアリング、バルブ部品、ライニング。;

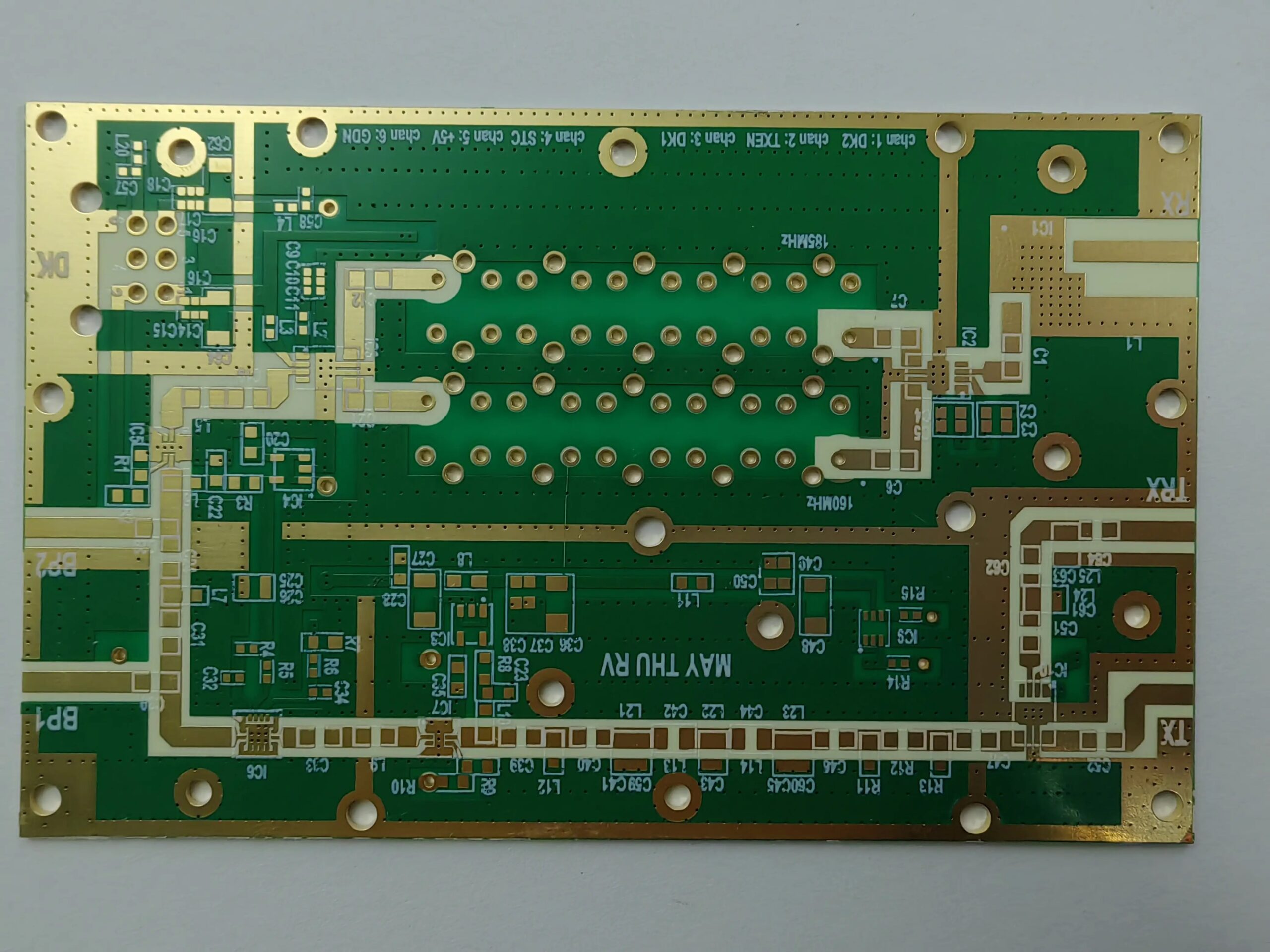

エレクトロニクス: 回路基板、コネクタ、電子部品の絶縁材。

自動車:燃料ライン用のブッシング、ホース、コーティング;

食品・飲料:コンベアベルト、金型、容器;

医学: カテーテル、埋め込み型デバイス、実験器具。

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

Due to PTFE’s extremely low coefficient of friction (only 0.04) and excellent self-lubricating properties, it is widely used in the manufacture of sliding bearings, guide rails, and piston rings, which can reduce equipment wear and save on production costs.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

ハンザ社の改質PTFEの仕様

- サイズの説明

- バージンPTFEの特性

- Etched PTFE Properties

- 改質PTFEシート

| タイプ | Size Description |

| PTFE成形シート | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| PTFEスカイブシート | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| 延伸PTFEシート | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| プロパティ | ユニット | 結果 |

| 見かけ密度 | g/m² | 2.10~2.30 |

| 引張強度(分) | MPa | 15.0 |

| 破断伸び(分) | % | 150 |

| 絶縁強度(分) | KV/mm | 10 |

| プロパティ | ユニット | 結果 |

| 密度 | g/cm³ | ≥2.18 |

| 抗張力 | MPa | ≥30 |

| 破断時の伸び | % | 300 |

| NO. | Filled Compound And | 引張強度 Mpa min | 究極の強さ % 分 | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | 20% ガラスファイバー | 10 | 120 | 16 |

| 2 | 25% ガラスファイバー | 10 | 100 | 16 |

| 3 | 20%グラスファイバー 5%グラファイト | 10 | 120 | 16 |

| 4 | 60%ブロンズ | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

関連製品

PTFEシート

ポリテトラフルオロエチレンシートは、一般的にPTFEシートと呼ばれます。または、テフロンシートと呼ばれることもあります。もちろん、この2つの名称は同じ製品を指しますが、「テフロン」はデュポン社製のPTFEです。

一般的に、これらのシートはフッ素と炭素の結合でできています。これがポリテトラフルオロエチレンという名称の由来です。

炭素結合が強いため、高分子シートとみなされます。これが、今日多くの用途で広く使用されている理由です。

の種類 PTFE 利用可能なシート

テフロンシートは幅広いカスタマイズオプションを備えているため、幅広い基準で分類できます。

理想的には、次のようになります。

- 粘着剤付きPTFEシート - 片面に粘着剤付き基材が貼付されています

- サイズに合わせてカットされたPTFEシート - PTFEはお客様の特定の要件に応じてカットされます

- さまざまな厚さのシート - PTFEシートは3mm厚または100mm厚から選択できます。

つまり、利用可能なオプションは、独自のカスタマイズオプションによって異なります。さらに重要なのは、これがPTFEシートの価格にも影響することです。

汎用PTFEシート材料

もちろん、カスタマイズにより、テフロンシートは特定の用途に適しています。ただし、汎用PTFEシートを選択することもできます。

| PTFEシート材料の特性 | 評価 |

| 抗張力 | 貧しい |

| 紫外線耐性 | 良い |

| 硬度 | 中程度の柔らかさ |

| 衝撃強度 | 良い |

| 寸法 | 6×6インチから48×48インチまで様々です |

ガラス充填PTFEシート

機械的強度、耐衝撃性、耐摩耗性を向上させたシートをお探しの場合は、ガラス繊維入りのシートをお選びください。多くの場合、これらのシートには約25%のガラス繊維が含まれています。

ポリテトラフルオロエチレンシートの特徴

これらのシートを選択する理由はたくさんあります。

- 高い融点を持つ樹脂は、ほとんどの継続使用に最適です。

- PTFE素材は高温でも安定した状態を保ちます。温度範囲は-200℃~+260℃です。

- 優れた非粘着性で知られています

- 優れた断熱性

- 摩擦係数は比較的低い

- 標準的なプラスチック素材よりも優れた耐腐食性

- 疎水性があり、水をはじく傾向がある

- 化学的に不活性

- FDA承認済み

- ガンマ線に敏感

バージンPTFEシートでは、これらのすべての特性が備わっていない場合があります。そのため、PTFE素材を強化する必要があります。これらのシートは、100%の純粋なポリテトラフルオロエチレン樹脂から作られています。

興味深い 2 つのシートを比較してみましょう。

| バージンPTFEシート | 機械用PTFEシート |

| · 100%純粋ポリテトラフルオロエチレン樹脂製

· 高い物理的特性 · 通常のアプリケーション · 添加物なし |

· 再生ポリテトラフルオロエチレン樹脂製

· 物理的特性が低い · 高性能アプリケーション · 特性を向上させる添加剤を充填 |

PTFEシートを出荷できる形態

これらの材料は平板またはロール状の状態で入手できます。梱包方法はシートの厚さによって異なります。

ほとんどの場合、PTFEシートロールの厚さは0.093インチ未満です。これより厚いポリテトラフルオロエチレンシートをロールすることは推奨されません。

用途

PTFE 材料シートを機械加工または加工して、次のようなさまざまな部品を作ることができます。

- PTFEガスケット

- PTFEブッシング

- PTFEライニング

- PTFEスライディングプレート

- PTFE電気絶縁部品

- PTFEワッシャー