The primary function of PTFEチューブ is to transport gases and liquids. This is especially true in the chemical industry, where highly corrosive liquids are common and require specialized pipes. PTFE is the best choice. As a manufacturer with 25 years of experience in PTFE production, I’ll provide you with a comprehensive guide to PTFE tubing in this article.

What is PTFE Tubing?

As the name suggests, this is a tube made of PTFE. You might be wondering why PTFE is chosen over other materials for a tube. It’s because it possesses properties that other plastics don’t possess. First, PTFE is chemically stable. Secondly, it has an incredible temperature range. Furthermore, it possesses self-lubricity, wear resistance, and mechanical strength. These properties make it stand out among other plastics, leading to its increasing popularity and adoption.

Benefit of PTFE Tubing

-

Widely Temperature Resistant

PTFE tubing is not only resistant to high temperatures but also capable of continuous operation in low-temperature environments. Its temperature resistance range is -200°C to 260°C. Therefore, PTFE tubing is used in high-temperature applications such as the chemical industry, for transporting high-temperature fluids, and in low-temperature environments such as space, as fuel pipelines to withstand the extremely harsh environment of space.

-

Chemical Stability

PTFE is chemically inert, unreactive with all chemicals, and resistant to strong acids and alkalis. Therefore, PTFE piping can transport highly corrosive liquids while protecting itself. Operators also don’t need to worry about their own safety, as PTFE piping won’t corrode and cause leaks. If you’re the owner of a chemical plant, this can effectively protect your employees’ lives and save you from unnecessary worry.

-

Impermeable

PTFE’s unique molecular structure gives it excellent impermeability. PTFE is composed of many tetrafluoroethylene monomers, each of which contains three chemical elements: one carbon atom and two fluorine atoms. Each carbon atom is linked by two fluorine atoms, forming a solid fluorinated layer that isolates water molecules. This is why PTFE is impermeable to water.

-

Non-stick Property

Many people are probably familiar with this property. Do you have a nonstick pan at home? Or perhaps you’ve heard of it. Yes, the coating in nonstick pans is PTFE. Imagine using a nonstick pan and feeling the distinct separation of water and oil from the pan.Unlike ordinary iron pans, the food tends to stick to the bottom in large chunks if you’re not careful while stir-frying.PTFE tubing, leveraging its non-stick properties, is often used to transport fluids like juice and beverages. It prevents the liquid from sticking and is easy to clean.

-

Low Friction

PTFE has an extremely low coefficient of friction, ranging from 0.005 to 0.15, so PTFE tubing can facilitate fluid flow when transporting fluids. When used as a medical catheter, it can reduce friction with human tissue.

-

柔軟性

Tubes made of PTFE are very tough and have a high degree of bending. They can work stably and maintain their original characteristics in a bent state for a long time. They have a long service life and do not need to be replaced frequently.

-

生体適合性

Based on this property, PTFE tubings are made into artificial blood vessels for the treatment of diseases. Not only will they not cause harmful reactions and rejection reactions, but they can also prevent artificial blood vessels from sticking to human tissues.

Types of PTFE Tubing

-

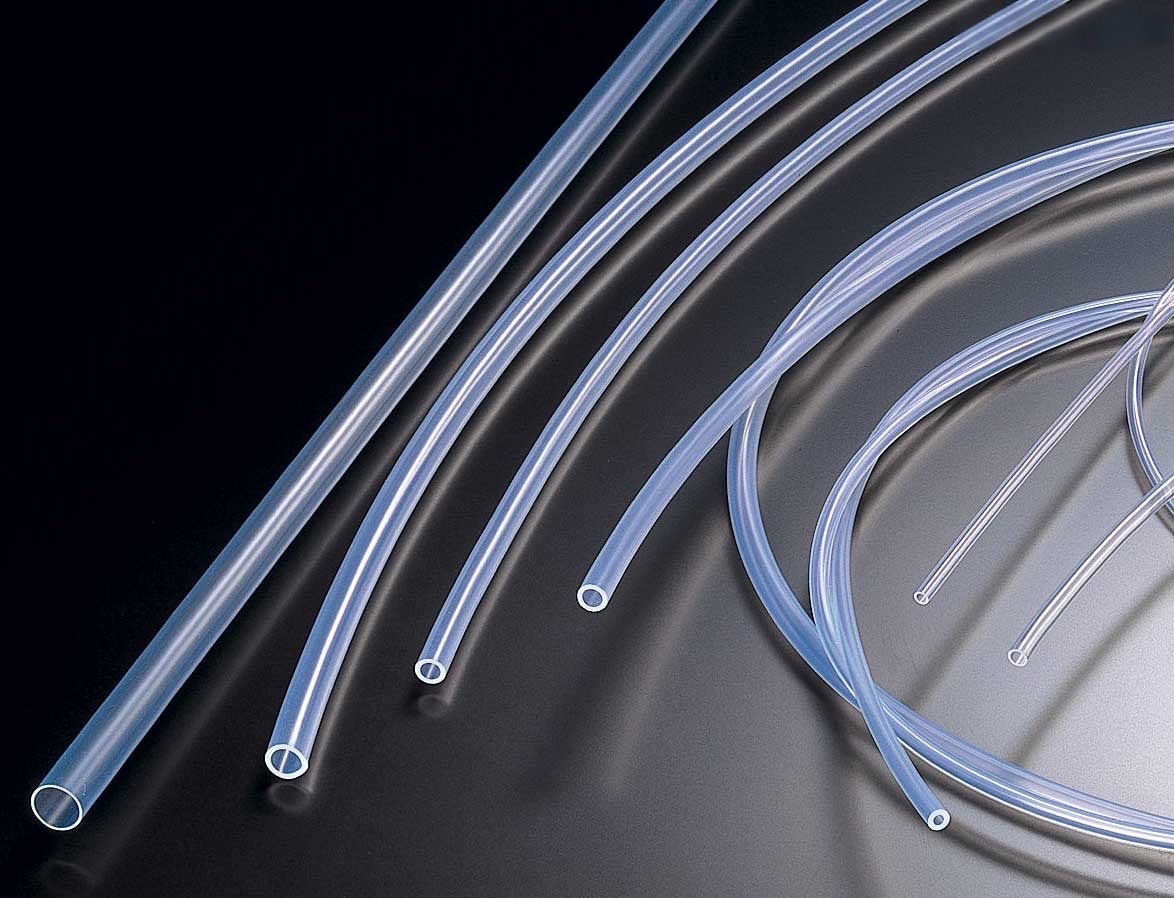

Standard Tubing

Standard PTFE tubes are generally used in various fields, and general gas and liquid transportation is not a problem.

-

Thick-walled Tubing

Thick-walled PTFE tubes are generally not very long, and the difference between the inner and outer diameters is relatively large. From their appearance, it is obvious that these tubes are more pressure-resistant and have higher mechanical strength.

-

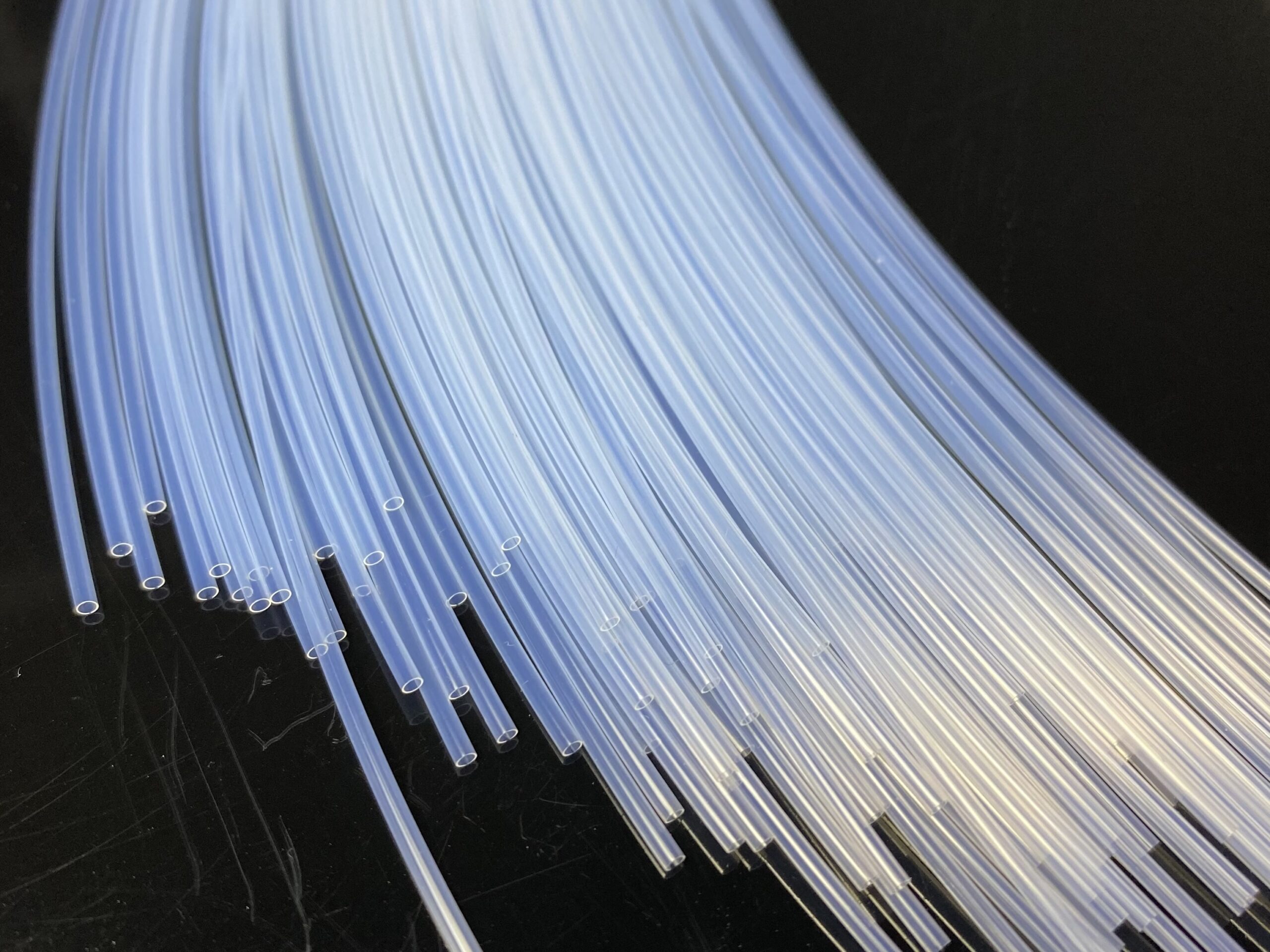

Thin-walled Tubing

Compared to thick-walled PTFE tubes, thin-walled tubes are less pressure-resistant and are more suitable for low-pressure applications.Additionally, it occupies a limited space and is generally used for laboratory catheters or as insulating protective covers for electronic components.

-

Film cast Tubing

This PTFE Tubing adopts casting technology, and the produced pipe wall is thinner, which is suitable for occasions requiring anti-permeation and high sealing performance.

-

Ram-extruded Tubing

Using the stamping process, the produced tubes are more uniform and have a larger diameter, making them suitable for applications that require high tensile strength.

The Production Process of PTFE Tubing

Step1.Raw material preparation

Prepare the PTFE resin powder or granules, and sometimes add fillers such as graphite, carbon powder, etc., along with a lubricant to form a paste-like slurry.

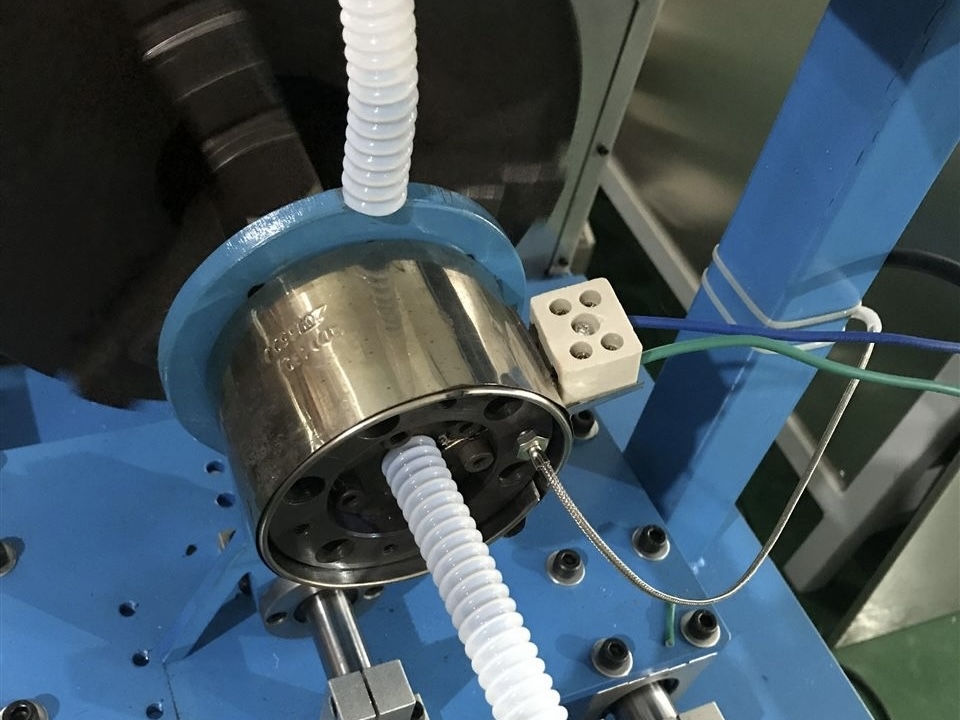

Step2.Extrusion Molding

Place the prepared paste-like slurry into the extruder, and let it be extruded and molded according to the preset program. At this stage, the PTFE tubing is very fragile and does not yet have pressure resistance.

Step3.High temperature sintering

This is aimed at eliminating the microscopic porosity of the PTFE tube, enhancing its physical properties, reducing its density, and making it more durable.

Step4.Cooling and shaping

Allow the sintered PTFE tubing to cool and solidify, so that it stabilizes and retains its final shape and properties.

Step5.Post-processing

Cut and polish the already fabricated PTFE tubing. The tube is cut to the required dimensions, and some may also undergo polishing or coating treatments to enhance their wear resistance.

It’s important to note that due to the extremely high melting point of PTFE, its processing can be quite challenging. As a result, the production capacity of PTFE tubing may be limited.

Applications of PTFE Tubing

-

化学産業

PTFE tubing is often used as a pipeline for transporting various highly corrosive liquids, connecting chemical storage containers. It can withstand the toxicity of chemicals, preventing reactions with the pipeline and maintaining the quality of the chemicals.

-

医療業界

Common uses of PTFE tubing include serving as pipelines for transporting chemical agents, as well as being made into catheter tubes, artificial blood vessels, and medical syringes.

-

Electrical Industry

PTFE has excellent insulating and anti-static properties, which makes it ideal for use as the insulation layer in wires and cables. It helps protect operators from electrical hazards.

PTFE tubing is actually right around you. It’s present in the car you use every day. It is used as a fuel transfer pipe, capable of withstanding the high temperatures of the engine.

-

食品・飲料

If you were the owner of a food factory, PTFE tubing would definitely be your top choice for transporting fruit juice and beverages. It not only prevents liquid leakage but also reduces liquid adhesion, making it easy to clean. Additionally, it won’t affect the safety of the food, ensuring the health and safety of consumers.

How to Choose When Using PTFE Tubing?

If you’re looking to buy PTFE tubing, you must find a trustworthy manufacturer. It can’t be a trading company that simply buys and sells; it should be a genuine producer of PTFE. You need to do your due diligence—check if the company has a good reputation in the industry. Ensure that their PTFE tubing is certified by authoritative institutions and meets regulatory standards during the manufacturing process. These are all important factors to consider.

-

Adaptability

When choosing PTFE tubing, product compatibility is a crucial factor. The right PTFE tube depends on the specific application. You need to consider the wall thickness, tube diameter, and whether to use a capillary tube, standard hose, or sleeve. For instance, Hansa’s capillary tubes can reach an inner diameter as small as 0.3 mm, which is relatively rare in the market. This makes it especially suitable for precise applications where small diameters are essential.

-

Filler

PTFE tubing can be infused with different fillers to enhance its properties. When selecting PTFE tubing, you can choose tubes with various fillers depending on the specific application.

1.Glass Filled

Adding fiberglass significantly improves the rigidity, wear resistance, and creep resistance of PTFE tubing. This allows it to maintain good performance and stability even under high temperature and pressure, ensuring reliable operation. However, it’s important to note that fiberglass is abrasive and may cause wear on machinery. Also, PTFE tubing with fiberglass should be kept away from chemicals that could corrode glass.

2.Carbon Filled

PTFE tubing with added carbon powder has a lower coefficient of friction, which improves its strength and makes it more wear-resistant. At the same time, it enhances its electrical and thermal conductivity, providing anti-static properties. This also significantly increases the tubing’s resistance to corrosion, especially against soft metals. Carbon-filled PTFE tubing is commonly used in electronic devices and the semiconductor industry.

3.Graphite Filled

Graphite greatly enhances the lubricity of PTFE tubing, while also improving its resistance to high temperatures and corrosion. PTFE tubing with graphite is commonly used in sealing materials, bearings, and mechanical components.

4.Bronze Filled

Bronze-filled PTFE tubing improves wear resistance and provides high mechanical strength, making it ideal for high-load, high-speed mechanical components. Additionally, the thermal conductivity of the tubing is significantly enhanced.

Service Life of PTFE Tubing

Generally, if PTFE tubing is used in a good working environment, its lifespan can range from 10 to 20 years. However, several factors can affect its longevity. If the temperature exceeds 260°C or if the tubing is exposed to extremely harsh conditions, its lifespan will likely be reduced, and it could last as little as 5-6 years.

How to Maintain PTFE Tubing?

-

Cleaning

If you want to extend the lifespan of PTFE tubing, proper maintenance is essential. Regular cleaning is key. You should use warm water and a mild detergent to keep the tubing in good condition.

-

Checking

Regular inspections are also crucial. If you notice any signs of wear, cracks, or other abnormalities in the PTFE tubing, it’s important to repair or replace it promptly to prevent any potential failures or safety issues.

How to Replace PTFE Tubing?

Next, I will use the PTFE pipes used to transport sulfuric acid in a chemical plant as an example to show you how to properly replace them.

Step1.Preparation stage

You’ll need to measure the inner and outer diameters of the old PTFE pipe, prepare a new PTFE pipe of the same specifications, and its corresponding fittings and gaskets. Don’t forget the installation tools as well. If it’s a threaded connection, prepare sealing tape; if it’s a flanged connection, prepare a wrench and screwdriver.

Step2.Ensure safety

Shut down the sulfuric acid transport system and drain the sulfuric acid from the old pipelines. Wear protective clothing during the operation.

Step3.Disassembly

If it’s a flange connection, remove it with a wrench or screwdriver. If it’s a threaded connection, remove the sealing tape.

Step4.Install

Cut the new PTFE pipe, making sure the cut is clean and smooth before installation. If it’s a threaded connection, wrap it securely with sealing tape. If it’s a flange connection, ensure there are no gaps between the flange and the gasket, and guarantee a tight, compacted fit.

Future trends of PTFE pipes

The market demand for PTFE pipes continues to expand, and its sales prospects are very promising. At the same time, researchers are also engaged in technological innovation, studying how to efficiently recycle PTFE pipes to address environmental pressures.

結論

I’ve introduced PTFE pipes from multiple perspectives; do you understand now? Thanks to the excellent properties of PTFE, PTFE pipes can be applied in various fields and have a very bright future. If you have any ordering needs, please contact us. We are a manufacturer specializing in PTFE products for 25 years.

よくある質問

Is Teflon Tubing the same as PTFE?

Yes, Teflon is just another name for PTFE. It was once a registered trademark of DuPont, but now belongs to Chemours.

Is PTFE Tubing safe?

I believe PTFE is safe as long as it is used within its safe temperature range. Its safety has been certified by organizations such as ISO, FDA, and CFSA. When used correctly, PTFE is safe and non-toxic, posing no harm to the human body. Danger only arises under improper handling.

The Difference between PTFE tubing and PFA tubing

PTFE tubing is opaque and milky white, while PFA tubing is highly transparent. PTFE tubing can be brittle under certain conditions, while PFA tubing has high toughness and is not easily broken.

The Influence of PTFE Tubing on the environment

PTFE is difficult to degrade, and if it is disposed of carelessly, it will damage the environment. However, it can still be effectively recycled.