Lembaran PTFE Dari Hansa

- Penggunaan: Segel dan pelumas untuk digunakan dalam berbagai media, serta isolasi listrik untuk digunakan pada berbagai frekuensi. Media kapasitor, isolasi kabel, isolasi instrumentasi listrik.

- Peralatan Pengolahan Kimia, Gasket/liner untuk pipa, katup, dan reaktor

- Sistem Penyegelan Flensa, Gasket penyegel suhu tinggi/tekanan tinggi (HTHP)

- Komponen Tahan Aus, Bantalan keausan gesekan rendah untuk pemandu linier dan bantalan

- Pelapis Anti-Korosi, Pelapis tangki asam/pelapis bak elektroplating (misalnya, tahan asam sulfat/nitrat)

Lembaran PTFE HANSA

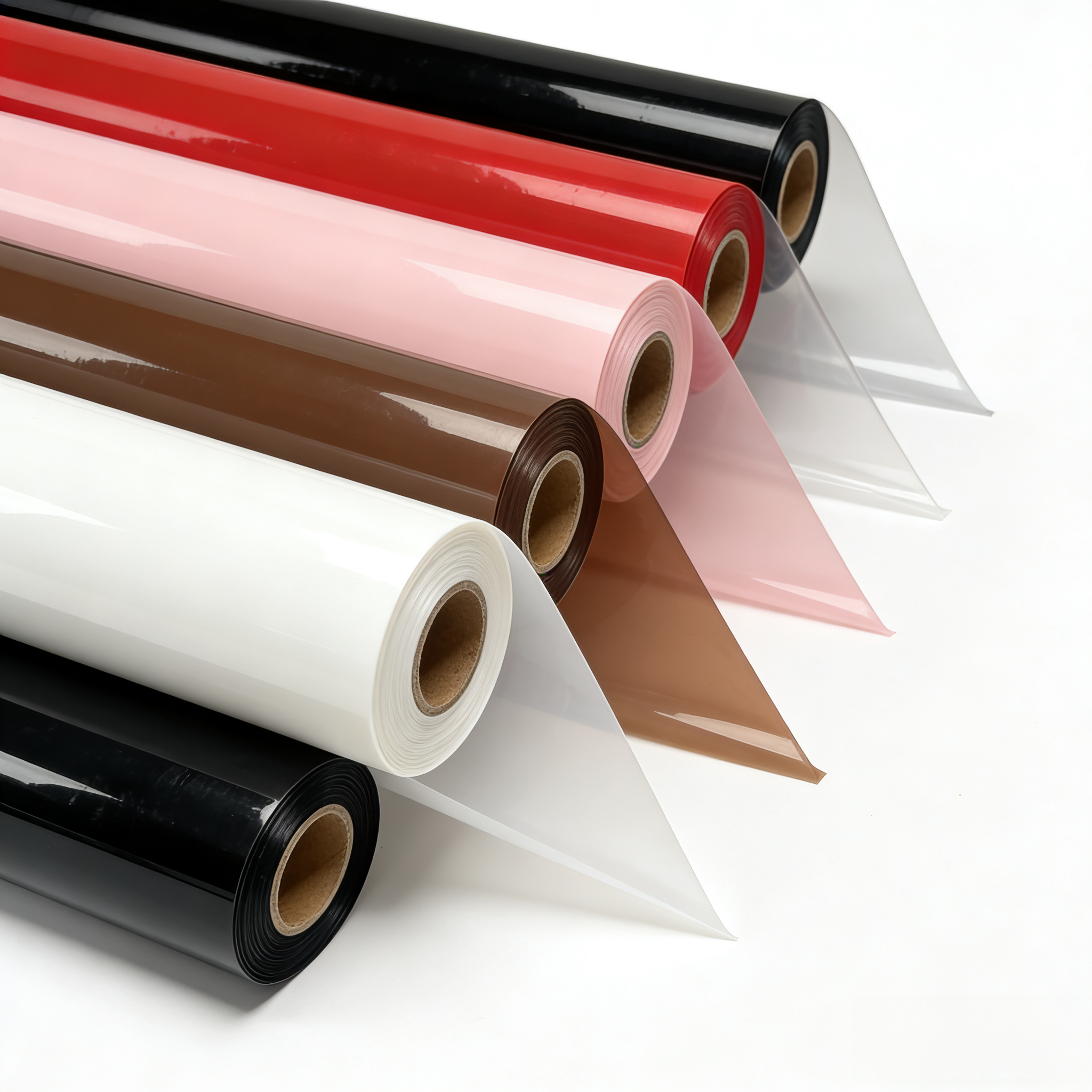

Hansa dapat menyediakan berbagai jenis lembaran atau film PTFE, baik Anda membutuhkan lembaran PTFE dalam bentuk gulungan, lembaran PTFE yang diperkuat, atau dipotong sesuai ukuran, kami selalu dapat menyediakan bahan berkualitas. Ukuran apa pun, warna apa pun, jenis apa pun, atau ketebalan apa pun. Kirimkan saja kebutuhan Anda dan dapatkan sampel gratis untuk memeriksa kualitasnya.

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

Ada berbagai jenis lembaran PTFE yang dapat dikategorikan dalam beberapa cara: 1. Berdasarkan proses pembuatan 2. Berdasarkan bahan pengisi/modifikasi 3. Berdasarkan warna 4. Berdasarkan aplikasi 5. Berdasarkan spesifikasi 6. Jenis khusus – termasuk lembaran PTFE berpori (umumnya dikenal sebagai “papan PTFE yang diperluas”)

Struktur mikro berpori yang dibuat melalui proses peregangan, digunakan dalam penyaringan, aplikasi membran bernapas, dan bidang biomedis.

Ukuran dapat disesuaikan, Penjualan eceran diperbolehkan. LEBAR MAKSIMAL mendekati 3Meter, KETEBALAN MAKSIMAL dapat mencapai 10mm+

Ukuran dapat disesuaikan, Penjualan eceran diperbolehkan. LEBAR MAKSIMAL dapat mencapai 2 Meter, KETEBALAN MAKSIMAL mendekati 600 mm.

Formulasi Pengisi Khusus untuk Mitigasi Aliran Dingin di PTFE dengan Butiran Mikro Kaca Biru, Barium Sulfat Putih, Silika Kuning.

Permukaan politetrafluoroetilen setelah perlakuan natrium bersifat hidrofilik, yang dapat diikat dengan lem biasa untuk memperluas jangkauan penerapannya.

Diproduksi melalui proses pencetakan ekstrusi, cocok untuk aplikasi lembaran yang lebih tipis dengan efisiensi produksi yang tinggi.

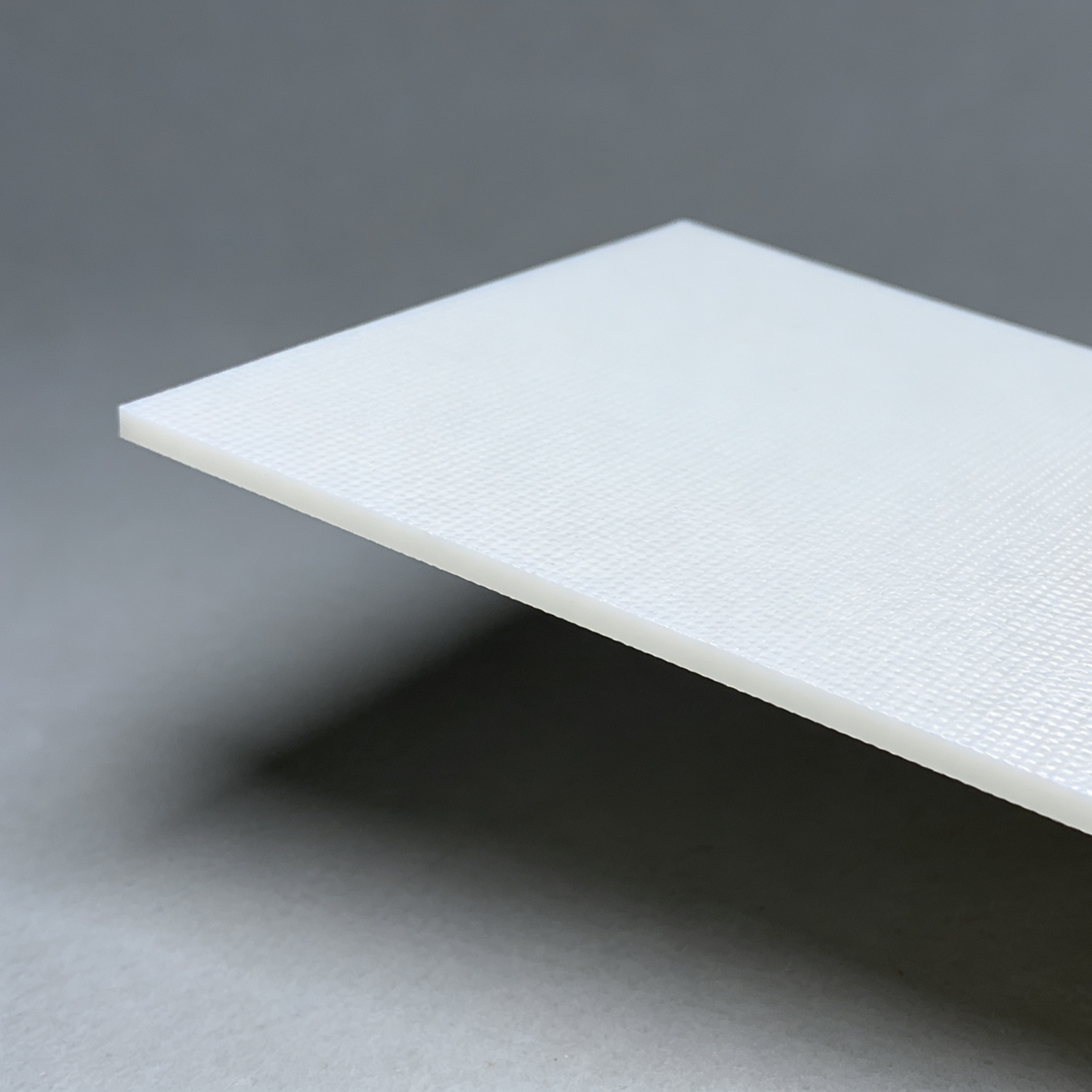

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

Fitur Utama Lembaran PTFE

Menunjukkan ketahanan terhadap tekanan dan mulur yang baik pada suhu kamar, meski dapat melunak pada suhu tinggi, cocok untuk aplikasi tegangan rendah.

Koefisien gesekan (COF) serendah 0,04, menampilkan permukaan halus dengan sifat pelumas otomatis yang menghilangkan kebutuhan akan pelumas eksternal.

Menunjukkan ketahanan terhadap korosi yang mampu menahan agen agresif dan sebagian besar media kimia (pH 0-14).

Kisaran operasional berkisar dari -200°C hingga +260°C untuk layanan berkelanjutan, dengan toleransi paparan jangka pendek hingga 300°C.

Aplikasi Lembaran PTFE

Industri: Segel, paking, bantalan, komponen katup, dan lapisan untuk pipa dan tangki.;

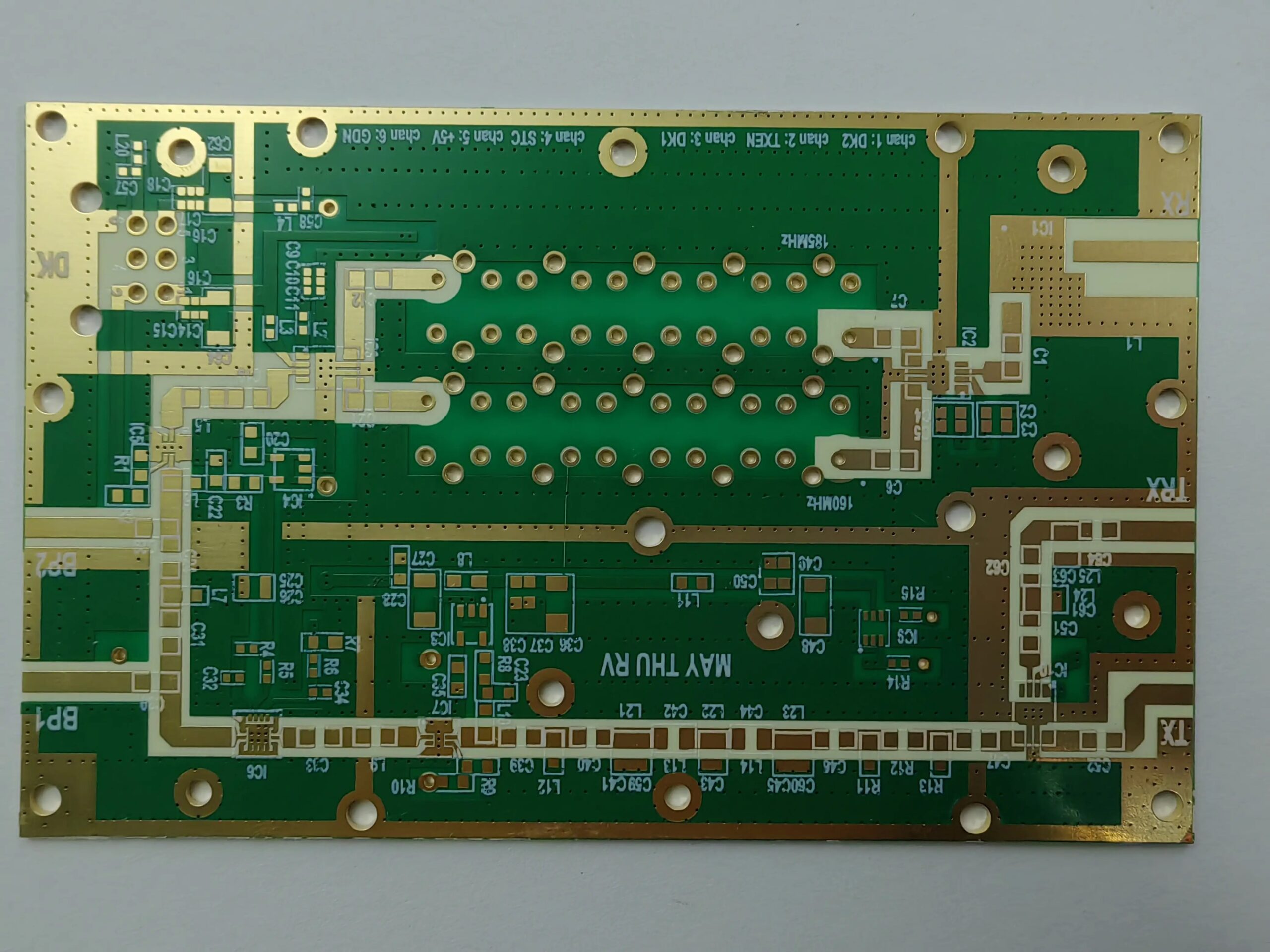

Elektronik: Isolasi untuk papan sirkuit, konektor, dan komponen elektronik;

Otomotif: Bushing, selang, dan pelapis untuk saluran bahan bakar;

Makanan & Minuman: Ban berjalan, cetakan, dan wadah;

Medis: Kateter, perangkat implan, dan peralatan laboratorium.

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

Due to PTFE’s extremely low coefficient of friction (only 0.04) and excellent self-lubricating properties, it is widely used in the manufacture of sliding bearings, guide rails, and piston rings, which can reduce equipment wear and save on production costs.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

Spesifikasi PTFE Modifikasi Dari Hansa

- Deskripsi ukuran

- Properti PTFE Perawan

- Etched PTFE Properties

- Lembaran PTFE yang dimodifikasi

| Jenis | Size Description |

| Lembaran Cetakan PTFE | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| Lembaran PTFE yang Dilapisi | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| Lembaran PTFE yang Diperluas | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| Properti | satuan | Hasil |

| Kepadatan tampak | gram/m² | 2.10~2.30 |

| Kekuatan tarik (min) | MPa | 15.0 |

| Perpanjangan saat putus (min) | % | 150 |

| Kekuatan dielektrik (min) | KV/mm | 10 |

| Properti | Satuan | Hasil |

| Kepadatan | g/cm³ | ≥2.18 |

| Kekuatan tarik | MPa | ≥30 |

| Perpanjangan pada saat putus | % | 300 |

| NO. | Filled Compound And | Kekuatan Tarik Mpa min | Kekuatan Tertinggi % min | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | Serat Kaca 20% | 10 | 120 | 16 |

| 2 | 25% Serat Kaca | 10 | 100 | 16 |

| 3 | 20%Glass Fiber 5%Grafit | 10 | 120 | 16 |

| 4 | 60%Bronze | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

Produk Terkait

Lembaran PTFE

Lembaran politetrafluoroetilena umumnya disebut lembaran PTFE. Atau, Anda juga dapat menyebutnya lembaran Teflon. Tentu saja, kedua nama tersebut merujuk pada produk yang sama, kecuali bahwa "Teflon" adalah PTFE yang dibuat oleh DuPont.

Secara umum, lembaran ini terbuat dari ikatan fluor dan karbon. Dari situlah namanya berasal, yaitu Polytetrafluoroethylene.

Karena ikatan karbonnya yang kuat, mereka dianggap sebagai lembaran molekul tinggi. Itulah sebabnya mereka umum digunakan dalam banyak aplikasi saat ini.

Jenis-jenis PTFE Lembar Tersedia

Anda dapat menggunakan kriteria yang luas untuk mengklasifikasikan lembaran Teflon. Hal ini dikarenakan adanya banyak pilihan penyesuaian.

Idealnya, Anda mungkin ingin:

- Lembaran PTFE dengan perekat – memiliki substrat perekat pada satu permukaan

- Potong lembaran PTFE sesuai ukuran – PTFE dipotong sesuai dengan kebutuhan spesifik Anda

- Lembaran dengan ketebalan bervariasi – Anda dapat memilih lembaran PTFE setebal 3mm atau setebal 100 mm

Singkatnya, pilihan yang tersedia bergantung pada pilihan penyesuaian yang unik. Yang lebih penting, ini juga akan menentukan harga lembaran PTFE.

Bahan Lembaran PTFE Serba Guna

Tentu saja, kustomisasi membuat lembaran Teflon cocok untuk aplikasi yang sangat spesifik. Namun, Anda dapat memilih lembaran PTFE untuk keperluan umum.

| Properti Bahan Lembaran PTFE | Peringkat |

| Kekuatan tarik | Miskin |

| Tahan UV | Bagus |

| Kekerasan | Sedang lembut |

| Kekuatan dampak | Bagus |

| Ukuran | Bervariasi tetapi bisa berukuran 6x6 inci hingga 48x48 inci |

Lembaran PTFE Isi Kaca

Jika Anda mencari lembaran dengan kekuatan mekanis, benturan, dan ketahanan abrasi yang lebih baik, pilihlah lembaran dengan serat kaca. Dalam kebanyakan kasus, lembaran ini memiliki sekitar 25% serat kaca

Fitur Lembaran Polytetrafluoroethylene

Ada banyak alasan untuk memilih lembaran ini:

- Tingkat leleh yang tinggi membuat resin sempurna untuk sebagian besar layanan berkelanjutan

- Pada suhu tinggi, material PTFE akan tetap stabil. Kisaran suhunya adalah -200°C hingga +260°C.

- Dikenal karena sifat anti lengketnya yang unggul

- Sifat isolasi yang unggul

- Koefisien gesekan relatif rendah

- Ketahanan korosi lebih baik dibandingkan bahan plastik standar

- Mereka bersifat hidrofobik – mereka cenderung menolak air

- Inert secara kimia

- Apakah disetujui FDA?

- Sensitif terhadap radiasi gamma

Terkadang, lembaran PTFE murni Anda tidak menawarkan semua fitur ini. Itulah alasannya Anda harus memperkuat material PTFE. Lembaran ini terbuat dari resin Polytetrafluoroethylene murni 100%.

Mari kita bandingkan dua lembar yang menarik:

| Lembaran PTFE Perawan | Lembaran PTFE Mekanik |

| · Terbuat dari resin Polytetrafluoroethylene murni 100%

· Sifat fisik yang tinggi · Aplikasi normal · Tanpa bahan tambahan tambahan |

· Terbuat dari resin Polytetrafluoroethylene yang diproses ulang

· Sifat fisik rendah · Aplikasi kinerja tinggi · Diisi dengan aditif untuk meningkatkan sifat-sifatnya |

Formulir Pengiriman Lembaran PTFE

Anda bisa mendapatkan bahan-bahan ini dalam bentuk datar atau gulungan. Metode pengemasan bergantung pada ketebalan lembaran.

Dalam kebanyakan kasus, gulungan lembaran PTFE memiliki ketebalan kurang dari 0,093″. Jika tidak, menggulung lembaran Polytetrafluoroethylene dengan ketebalan yang lebih tinggi tidak disarankan.

Penggunaan

Anda dapat mengerjakan atau membuat lembaran bahan PTFE untuk membuat banyak komponen seperti:

- Gasket PTFE

- Bushing PTFE

- Lapisan PTFE

- Pelat geser PTFE

- Bagian isolasi listrik PTFE

- Mesin cuci PTFE