परिभाषा

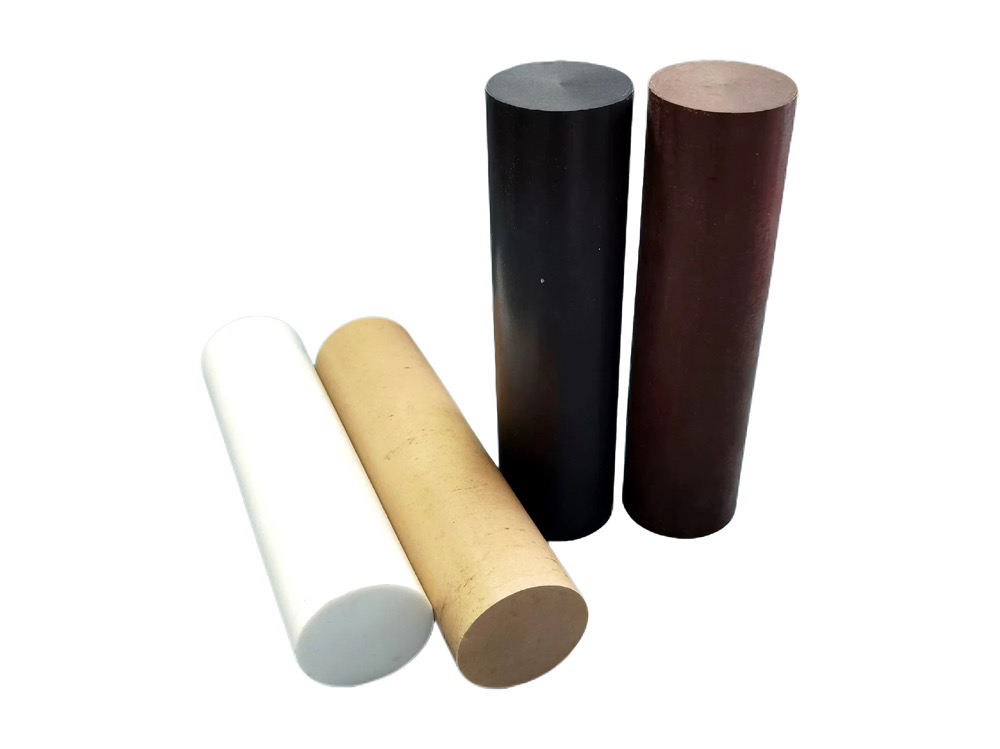

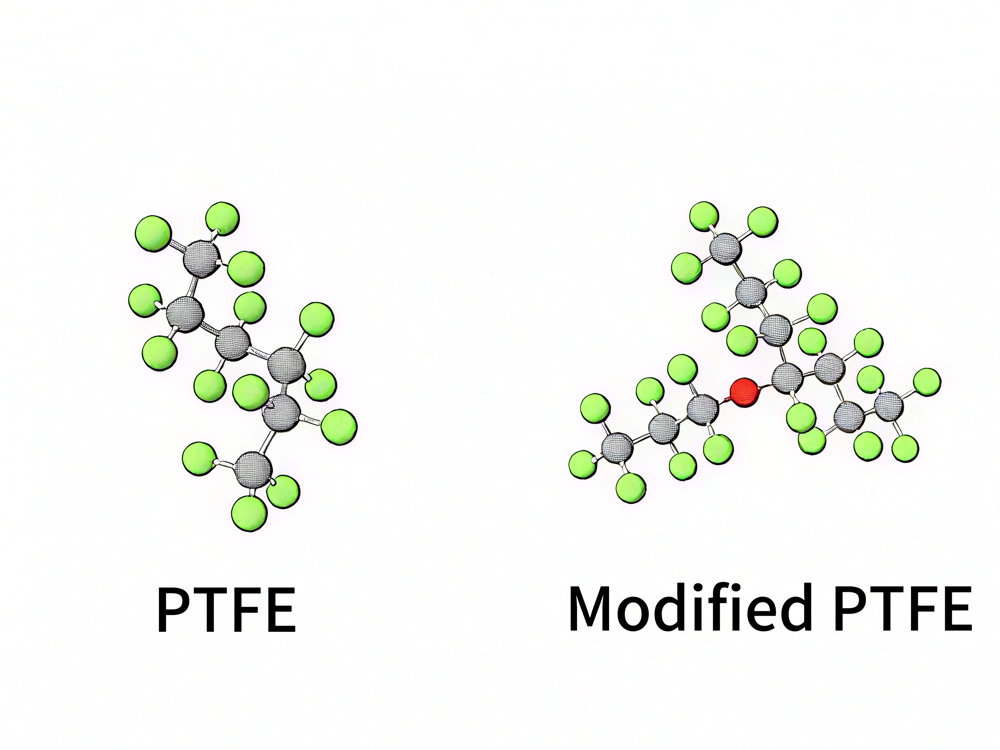

Modified PTFE(also called Modified Teflon) is made by processing pure PTFE (Polytetrafluoroethylene) through special methods. It keeps the original advantages of PTFE while improving specific properties for better performance in certain uses.

Modification Methods

Filler Modification

This method mixes PTFE with different fillers to improve certain properties. Fillers can be used alone or combined, depending on the performance needed. Here are some common fillers and their functions:

Inorganic Fillers

Glass Fiber: Improves wear resistance, creep resistance, and stiffness

Carbon Fiber: Increases strength, heat transfer, and wear resistance

Graphite: Boosts wear resistance and lubrication

Molybdenum Disulfide: Enhances lubrication

Metal Fillers

Copper Powder: Improves heat transfer and wear resistance

Nickel Powder: Increases corrosion resistance and strength

Polymer Fillers

Polyimide: Improves creep resistance and high-temp stability

Polystyrene (PEEK, etc.): Increases wear resistance and stiffness

Chemical Treatment

This method changes the molecular structure of PTFE through chemical reactions. The most common is grafting modification, where monomers like styrene are grafted onto PTFE using gamma rays or electron beams. This boosts surface activity and bonding ability.

Surface Modification

Plasma Treatment: Uses plasma to add active groups to the surface. This improves wetting and bonding.

Laser Etching: Uses ultra-fast lasers to create tiny grooves. Often used for biosensors.

Background

PTFE is known for its excellent resistance to chemicals, low friction, and high temperature tolerance. But it also has weaknesses, like low strength and poor creep resistance. Modified PTFE solves these issues through targeted improvements.

गुण

Performance Comparison

| संपत्ति | Pure PTFE | संशोधित PTFE |

| घनत्व | 2.1–2.3 g/cm³ | 2.5–3.0 g/cm³ |

| तन्यता ताकत | 15–30 MPa | 20–50 MPa |

| तोड़ने पर बढ़ावा | 200%–500% | 5%–300% |

| Hardness (Shore D) | 50–65 | 60–85 |

| ढांकता हुआ ताकत | 15–25 kV/mm | 5–20 kV/mm |

रासायनिक गुण

| संपत्ति | Pure PTFE | संशोधित PTFE |

| रेंगना प्रतिरोध | 50%–100% | 5%–30% |

| Permeability | 1×10⁻¹⁰ cm³·cm/(cm²·s·Pa) | 1×10⁻⁴ cm³·cm/(cm²·s·Pa |

| तापीय स्थिरता | -200°C to 260°C | -200°C to 200°C |

Choosing the Right Modification

Sealing Materials: Use 25% glass fiber + 5% graphite. Reduces friction by 40%. Ideal for high-pressure valves.

Medical Catheters: Plasma-grafted with acrylic acid. Increases surface hydrophilicity, reduces protein sticking by 60%.

High-Frequency Circuit Boards: Modified with nano-Aluminum Oxide. Keeps dielectric constant stable at 2.1–2.3 (at 1 MHz), suitable for 5G.

Price

Prices vary widely depending on the type and application. Generally, it ranges from 99 to 280 RMB per kilogram.