Do you want to know the applications of teflon material or teflon products? Hansa has more than 20 years experence in Teflon Fabrication. We know at least 10 popular common uses of it, whether Industrial field, medical field or daily life. Let me tell you what they are used for.

What is Teflon?

Teflon, also named पीटीएफई, it’s one kind of plastic.People called it “The king of plastics”.

Uses of Teflon

रसायन उद्योग

- Teflon has a very strong chemical stability, it is almost unreactive with any chemicals and resistant to strong acids and alkalis. So, in the chemical industry, it is used for the lining of reactors. If you are also a factory owner in the chemical industry, Teflon lining will bema great product to protect your equipment from corrosion.

- Based on this property, it also used to be tubes for various highly corrosive liquids.

- Since Teflon also has non-stick properties, it is also used as a non-stick coating for injection molds in industry.

- When graphite is added to Teflon, it becomes more wear-resistant and has stronger self-lubricating properties.This material is often used to make seals such as gaskets for various pumps, valves, and pipes.Can effectively prevent liquid leakage.Some people also make it into wear-resistant plates.

Transportation Industry

एयरोस्पेस उद्योग

- Teflon has a wide temperature resistance range and can work continuously and maintain stable performance under temperature conditions of -200 to 260°C.Therefore, there is a Teflon coating on the surface of the aircraft, which can not only prevent freezing but also reduce resistance.

- In addition to its ability to function in low-temperature environments, Teflon can also be used in aircraft parts to exert its heat insulation function and act as a seal.Of course, Teflon is also an integral part of the radiator.

- The sealing function of Teflon mentioned above is also applicable to the sealing of aircraft hydraulic systems.

- In the harsh environment of space, Teflon can also protect the detector from the harsh conditions, allowing it to continue to work stably.

Automotive Sector

- Like airplanes, automobile accessories such as radiators and bearings also require Teflon materials.

- The engine oil seal, fuel delivery pipeline, and engine coolant delivery pipeline all utilize Teflon’s corrosion resistance and high temperature resistance.

Mechanical Field

- The friction coefficient of Teflon is extremely low, between 0.005-0.15.This means that it can be used as a coating for bearings, gears, and chains, effectively reducing friction between machines, extending their service life, and saving you costs.

- टेफ्लॉन शीट made by injection molding can be made into any complex shape you want. They are usually used to customize mechanical parts or fits.

Medical Field

- Teflon’s low friction properties are used in the coating of surgical instruments such as laparoscopic forceps and scalpels to reduce friction with human organs.

- It has biocompatibility and will not have adverse reactions when in contact with human blood, so it is made into implantable medical devices such as artificial blood vessels. Such as artificial blood vessels, artificial heart valves, artificial tissue stents etc.

- The surface coating of medical syringes is also made of Teflon material because it can effectively prevent it from sticking to the skin. Since Teflon is resistant to chemical corrosion, it can also protect the syringe from corrosion and extend its service life.

- Some Teflon tubes are used to make urinary catheters or medical equipment, such as hemodialysis equipment tubing.

Electrical and Insulation Fields

- Teflon has good electrical insulation, it is always used to make insulation layers for electronic components or wires and cables.If you are producing lithium batteries, it can also be used as the lining for the positive electrode mixing tank of lithium batteries.

- Teflon also has anti UV and anti weathering properties, which can be used as a surface coating for radar antenna covers.

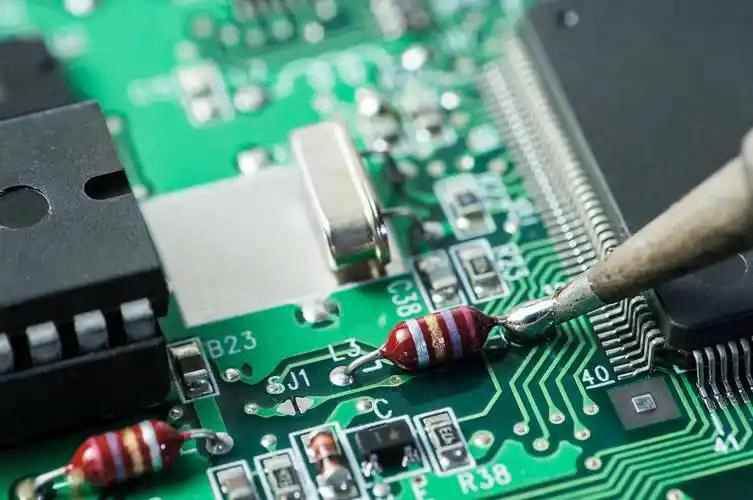

- The function of fiberglass is to improve the strength of materials, as well as enhance their heat resistance and insulation properties.So, these PTFE coated with fiberglass will be made into conveyor belts for transporting PCB boards, which will play an anti-static role during transportation.

- The insulating gasket used in the chip of the circuit board is made of Teflon material, which not only plays an insulating role but also protects the chip.

- Teflon’s high temperature resistance is also made into high temperature cloth, which is mostly used in solar photovoltaic modules, often in the form of laminated cloth or coating.

Food Processing Industry

- Do you often see food production processes in food advertisements? Then you must also know about food conveyor belts. Yes, that is also made of Teflon. Because of its good non-stick properties, it can prevent food from sticking and is easy to clean. Moreover, Teflon has been tested by the FDA and is food grade and is allowed to be used.

- Some food factories that produce beverages and juices use Teflon pipes to ensure food safety and hygiene.

- Teflon also has a special shaped product called a pall ring. Pall Ring is a modified Raschig ring with a unique shape, featuring a window and an inner curved tongue. This physical form increases its contact area with gas or liquid, accelerating the reaction rate.Often made into fermentation tanks and distillation towers.

Daily life

- In daily life, due to its high temperature resistance, it is also used on the surface of the pans to form a non-stick coating.Of course, in addition to pans, you can also use it for baking pans and other cookware that require high temperature resistance.

- Also, what you don’t know is that Teflon film can also be coated on eyeglass lenses, which can prevent water and dirt, reduce wear and tear, and extend the lifespan of the lenses.

- Teflon can be used as a coating for zippers. The Teflon coated zipper on the diving suit can help it resist corrosion from seawater.The coating on the surface of the fishing line is also Teflon, which is similar to the original.

- Did you use the electric iron before? The bottom of it has the Teflon coating. It is because of its high-temperature resistance. Someone else is the hairdressing tools such as curling iron.

- Teflon’s sealing property is common to see in daily life. In winter, you may use the thermos cup. Yes, the material of the sealing in it is Teflon.

Weaving and Dyeing Industry

- Some printing and dyeing equipment’s guide rollers are made of PTFE material, which can prevent dye contamination and reduce friction.

- Some fabrics treated with Teflon are waterproof, oil-proof and stain-resistant.

निर्माण उद्योग

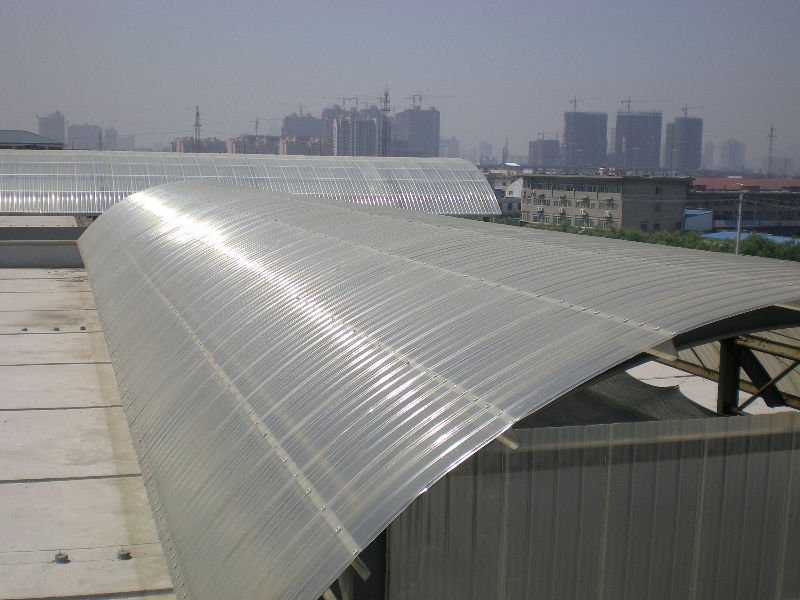

- In the field of architecture, Teflon materials with added fiberglass are used to make daylighting panels or building insulation.

laboratory

- Some experimental equipment in the laboratory will be made of Teflon, such as stirring rods and petri dishes. Because it is resistant to chemical corrosion, self-lubricating and not easy to stick, and it can be used for a long time.

- Some laboratory workbenches may also have Teflon coatings or even use Teflon sheets directly.

निष्कर्ष

To summarize, the common application areas of Teflon are chemical, aerospace and cars, mechanical,medical,electrical and insulation, food processing,daily life,weaving and dyeing, construction and laboratory.If you have a need to order Teflon products, please contact us.

FAQ:

Which can I use instead of teflon

This depends on the characteristics you need to choose. The closest material to PTFE is PEEK, but its disadvantage is that it is expensive and you need to have a sufficient budget. If you need wear-resistant and impact resistant materials, you can choose UHMW-PE; If you need high-temperature resistant materials, PI is a good choice; If you need a material with good self-lubricating properties, you can choose nylon;If you only need a material that can replace Teflon in a short period of time, you can purchase HDPE or PP.

Health of using teflon cookware

You don’t need to worry about Teflon cookware endangering your health, as they undergo national FDA food grade testing before being allowed for sale. In addition, Teflon itself is extremely resistant to high temperatures and can work continuously and stably within 260 ℃. The highest temperature you can reach when stir frying is around 200 ℃, so there is no need to worry.

Dangers of using teflon cookware

When using Teflon cookware, it is important to avoid high-temperature dry frying as it can cause the pot temperature to exceed 300 ℃, reaching the melting point of Teflon and causing it to decompose and release toxic gases. When you find that Teflon cookware is damaged, it should be replaced in a timely manner to prevent ingestion.

Advantages of using teflon

The benefits of Teflon are reflected in many aspects. For example, it has a wide range of applications, strong comprehensive performance, and is harmless to the human body.Also, the price of Teflon is lower than PEEK, making it relatively more cost-effective.

Disadvantages of using teflon

Due to its extremely high melting point, Teflon is difficult to process and time-consuming to machine. The price of Teflon is also higher than other plastic materials. There is a potential risk of high-temperature decomposition.