Lámina de PTFE de Hansa

- Uso: Sellos y lubricantes para diversos medios, así como aislamiento eléctrico para diversas frecuencias. Medios de condensadores, aislamiento de cables, aislamiento de instrumentación eléctrica.

- Equipos de procesamiento químico, juntas/revestimientos para tuberías, válvulas y reactores

- Sistemas de sellado de bridas, juntas de sellado de alta temperatura/alta presión (HTHP)

- Componentes resistentes al desgaste, almohadillas de desgaste de baja fricción para guías lineales y rodamientos.

- Revestimientos resistentes a la corrosión, revestimientos para tanques de ácido/baños de galvanoplastia (por ejemplo, resistentes al ácido sulfúrico/nítrico)

Láminas de PTFE HANSA

Hansa le suministra diferentes tipos de láminas o películas de PTFE, ya sea en rollo, reforzadas o cortadas a medida. Siempre le ofrecemos material de calidad. Cualquier tamaño, color, tipo o grosor. Simplemente envíenos sus requisitos y obtenga una muestra gratuita para comprobar la calidad.

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

Existen varios tipos de láminas de PTFE que se pueden clasificar de diversas maneras: 1. Por proceso de fabricación 2. Por rellenos/modificaciones 3. Por color 4. Por aplicación 5. Por especificaciones 6. Tipos especiales, incluidas las láminas de PTFE porosas (comúnmente conocidas como "placas de PTFE expandido")

Una estructura microporosa fabricada mediante un proceso de estiramiento, utilizada en aplicaciones de filtración, membranas transpirables y campos biomédicos.

Tamaño personalizable. Se permite la venta al por menor. Ancho máximo aproximado: 3 metros. Grosor máximo: 10 mm o más.

Tamaño personalizable. Se permite la venta al por menor. Ancho máximo de 2 metros y grosor aproximado de 600 mm.

Formulaciones de relleno especializadas para mitigación de flujo frío en PTFE con microperlas de vidrio azul, sulfato de bario blanco y sílice amarilla.

La superficie del politetrafluoroetileno después del tratamiento con sodio es hidrófila, por lo que se puede unir con pegamento común para ampliar su rango de aplicación.

Fabricado mediante un proceso de moldeo por extrusión, adecuado para aplicaciones de láminas más delgadas con alta eficiencia de producción.

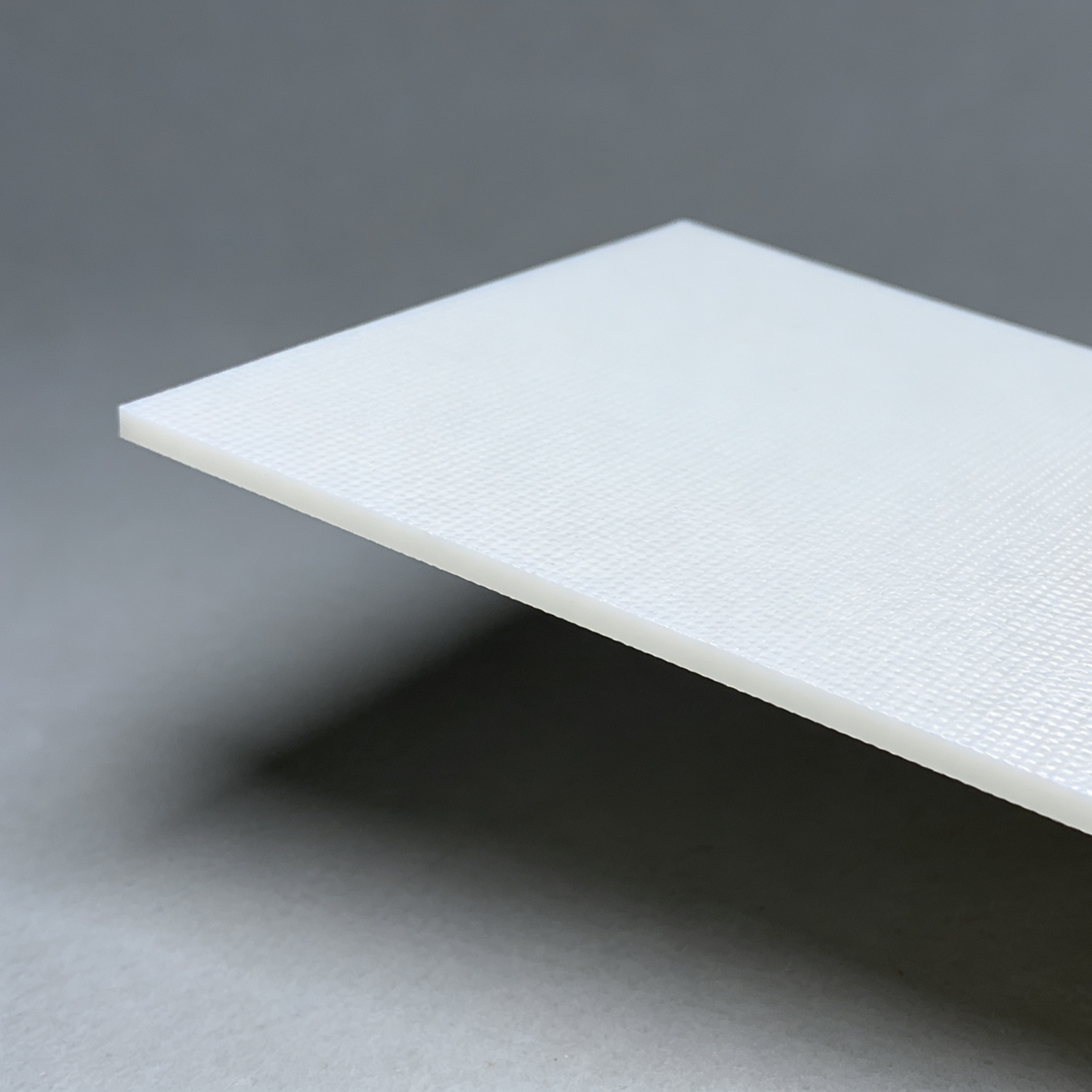

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

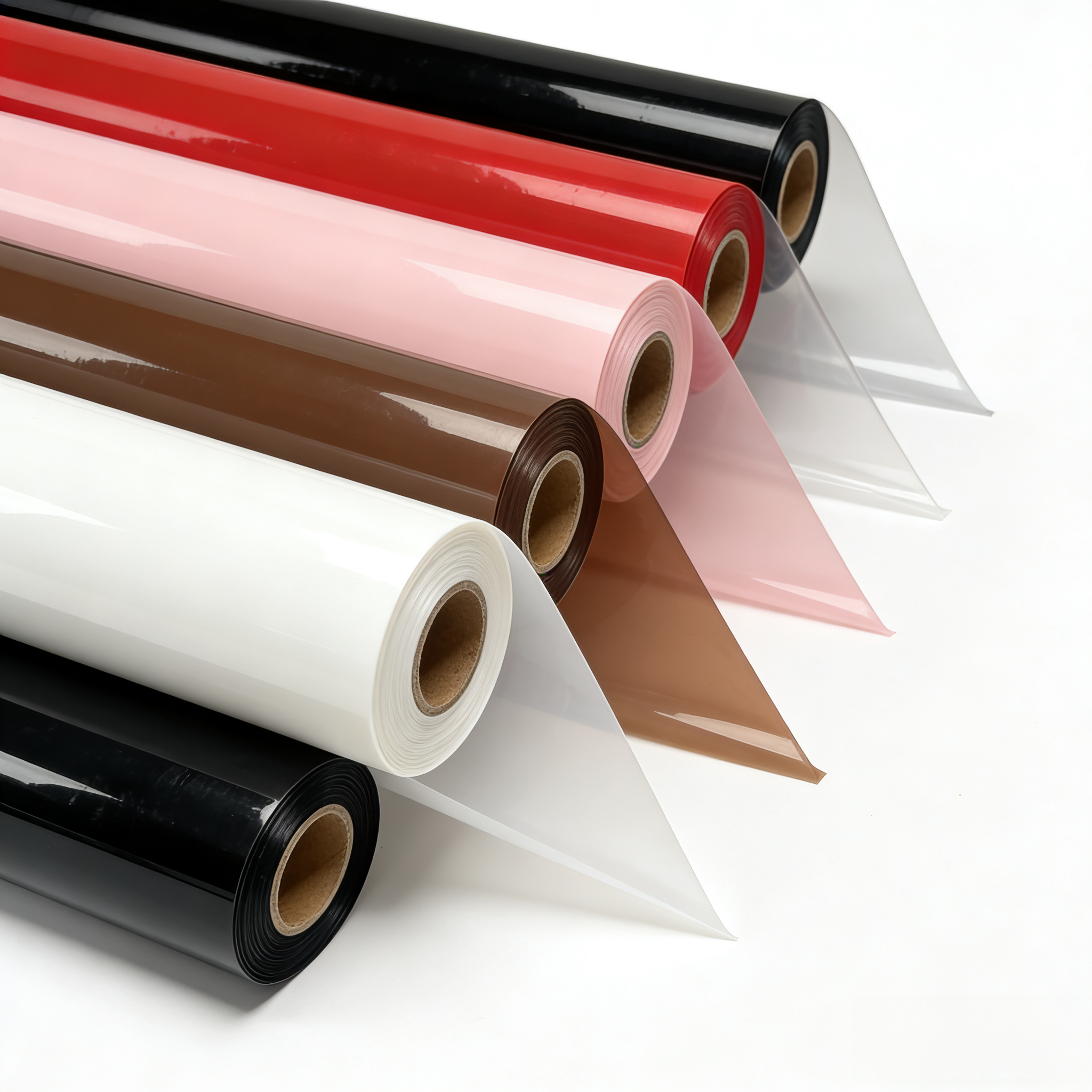

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

Características principales de la lámina de PTFE

Demuestra una resistencia favorable a la compresión y a la fluencia a temperatura ambiente, aunque puede ablandarse a temperaturas elevadas, lo que lo hace adecuado para aplicaciones de baja tensión.

Coeficiente de fricción (COF) tan bajo como 0,04, con una superficie lisa con propiedades autolubricantes que eliminan la necesidad de lubricantes externos.

Presenta resistencia a la corrosión capaz de soportar agentes agresivos y la mayoría de los medios químicos (pH 0-14).

El rango operativo abarca desde -200 °C a +260 °C para un servicio sostenido, con tolerancia a la exposición a corto plazo de hasta 300 °C.

Aplicación de la lámina de PTFE

Industrial:Sellos, juntas, cojinetes, componentes de válvulas y revestimientos para tuberías y tanques.

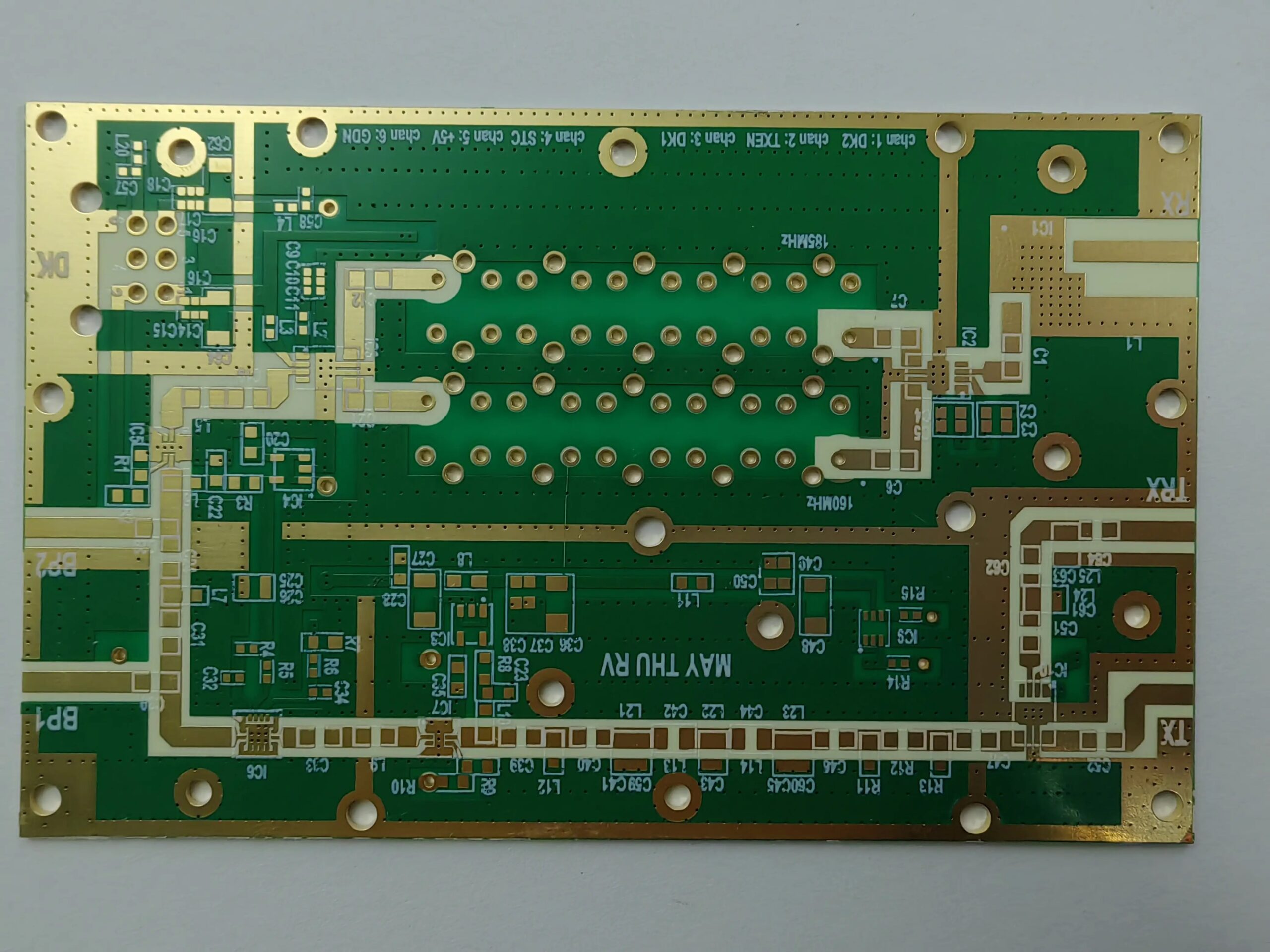

Electrónica:Aislamiento para placas de circuitos, conectores y componentes electrónicos;

Automotor:Bujes, mangueras y revestimientos para líneas de combustible;

Alimentos y bebidas:Cintas transportadoras, moldes y contenedores;

Médico:Catéteres, dispositivos implantables y material de laboratorio.

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

Due to PTFE’s extremely low coefficient of friction (only 0.04) and excellent self-lubricating properties, it is widely used in the manufacture of sliding bearings, guide rails, and piston rings, which can reduce equipment wear and save on production costs.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

Especificaciones del PTFE modificado de Hansa

- Descripción del tamaño

- Propiedades del PTFE virgen

- Etched PTFE Properties

- Lámina de PTFE modificada

| Tipo | Size Description |

| Lámina moldeada de PTFE | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| Lámina de PTFE biselada | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| Lámina de PTFE expandido | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| Propiedades | unidad | Resultado |

| Densidad aparente | g/m² | 2.10~2.30 |

| Resistencia a la tracción (mín.) | MPa | 15.0 |

| Alargamiento de rotura (mín.) | % | 150 |

| Resistencia dieléctrica (mín.) | KV/mm | 10 |

| Propiedades | Unidad | Resultado |

| Densidad | g/cm³ | ≥2.18 |

| Resistencia a la tracción | MPa | ≥30 |

| Alargamiento de rotura | % | 300 |

| NO. | Filled Compound And | Resistencia a la tracción Mpa min | Fuerza máxima % min | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | Fibra de vidrio 20% | 10 | 120 | 16 |

| 2 | Fibra de vidrio 25% | 10 | 100 | 16 |

| 3 | 20% Fibra de vidrio 5% Grafito | 10 | 120 | 16 |

| 4 | 60%Bronce | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

Productos relacionados

Láminas de PTFE

Las láminas de politetrafluoroetileno se denominan comúnmente láminas de PTFE. También se les conoce como láminas de teflón. Claro que ambos nombres se refieren al mismo producto, excepto que «teflón» es PTFE fabricado por DuPont.

En general, estas láminas se fabrican con enlaces de flúor y carbono. De ahí el nombre de politetrafluoroetileno.

Debido a sus fuertes enlaces de carbono, se consideran láminas de alto peso molecular, razón por la cual son comunes en muchas aplicaciones actuales.

Tipos de PTFE Sábanas disponibles

Se pueden utilizar criterios amplios para clasificar las láminas de teflón gracias a sus amplias opciones de personalización.

Lo ideal sería que usted desee:

- Láminas de PTFE con adhesivo: tienen un sustrato adhesivo en una superficie

- Láminas de PTFE cortadas a medida: el PTFE se corta según sus requisitos específicos

- Láminas de diferentes espesores: puede elegir la lámina de PTFE de 3 mm o 100 mm de espesor.

En resumen, las opciones disponibles dependen de las opciones de personalización únicas. Y lo que es más importante, esto también determinará el precio de la lámina de PTFE.

Material de lámina de PTFE de uso general

Por supuesto, la personalización hace que las láminas de teflón sean adecuadas para aplicaciones muy específicas. Sin embargo, puede optar por láminas de PTFE de uso general.

| Propiedades del material de lámina de PTFE | Clasificación |

| Resistencia a la tracción | Pobre |

| Resistente a los rayos UV | Bien |

| Dureza | Medio suave |

| Resistencia al impacto | Bien |

| Dimensiones | Varía, pero puede ser de 6 x 6 pulgadas a 48 x 48 pulgadas. |

Láminas de PTFE rellenas de vidrio

Si busca láminas con mayor resistencia mecánica, al impacto y a la abrasión, opte por las que contienen fibra de vidrio. En la mayoría de los casos, estas láminas contienen aproximadamente 25% de fibra de vidrio.

Características de las láminas de politetrafluoroetileno

Hay muchas razones para elegir estas sábanas:

- Su alto punto de fusión hace que la resina sea perfecta para la mayoría de los servicios continuos.

- El PTFE se mantiene estable a altas temperaturas. El rango de temperatura es de -200 °C a +260 °C.

- Conocido por sus propiedades antiadherentes superiores

- Propiedades de aislamiento superiores

- El coeficiente de fricción es relativamente bajo

- Mejor resistencia a la corrosión que el material plástico estándar.

- Son hidrófobos, es decir, tienden a repeler el agua.

- Químicamente inerte

- Están aprobados por la FDA

- Sensible a la radiación gamma

En ocasiones, su lámina de PTFE virgen no ofrece todas estas características. Por ello, es necesario reforzar el PTFE. Estas láminas están fabricadas con resina de politetrafluoroetileno puro 100%.

Comparemos dos hojas interesantes:

| Lámina de PTFE virgen | Lámina de PTFE mecánica |

| · Fabricado con resina de politetrafluoroetileno pura 100%

· Altas propiedades físicas · Aplicación normal · Sin aditivos adicionales |

· Fabricado con resina de politetrafluoroetileno reprocesada

· Bajas propiedades físicas · Aplicaciones de alto rendimiento · Lleno de aditivos para mejorar las propiedades. |

Formas en las que se pueden enviar láminas de PTFE

Estos materiales se pueden adquirir en láminas o rollos. El método de embalaje depende del grosor de la lámina.

En la mayoría de los casos, los rollos de láminas de PTFE tienen un espesor inferior a 0,093″. De lo contrario, no se recomienda el laminado de láminas de politetrafluoroetileno con espesores superiores.

Usos

Puede mecanizar o fabricar la lámina de material de PTFE para realizar muchas piezas como:

- Juntas de PTFE

- casquillo de PTFE

- revestimiento de PTFE

- Placa deslizante de PTFE

- Piezas de aislamiento eléctrico de PTFE

- Arandelas de PTFE