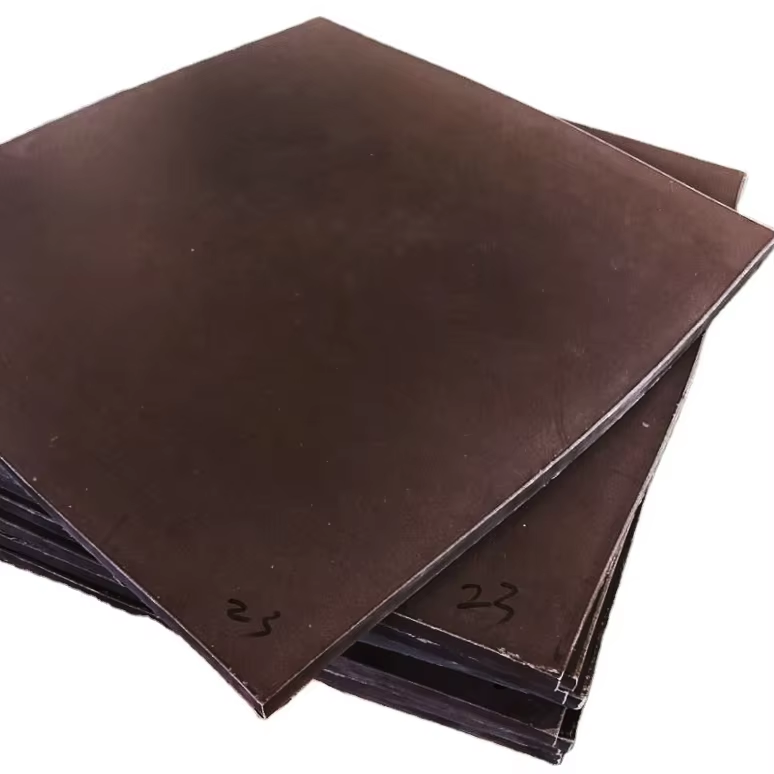

PTFE Sheet From Hansa

- Usage:Seals and lubricants for use in a variety of media, as well as electrical insulation for use at various frequencies. Capacitor media, wire insulation, electrical instrumentation insulation.

- Chemical Processing Equipment,Gaskets/linersfor pipelines, valves, and reactors

- Flange Sealing Systems,High-temperature/High-pressure (HTHP) sealing gaskets

- Wear-Resistant Components,Low-friction wear padsfor linear guides and bearings

- Corrosion-Resistant Linings,Acid tank/electroplating bath liners(e.g., sulfuric/nitric acid resistance)

HANSA PTFE Sheets

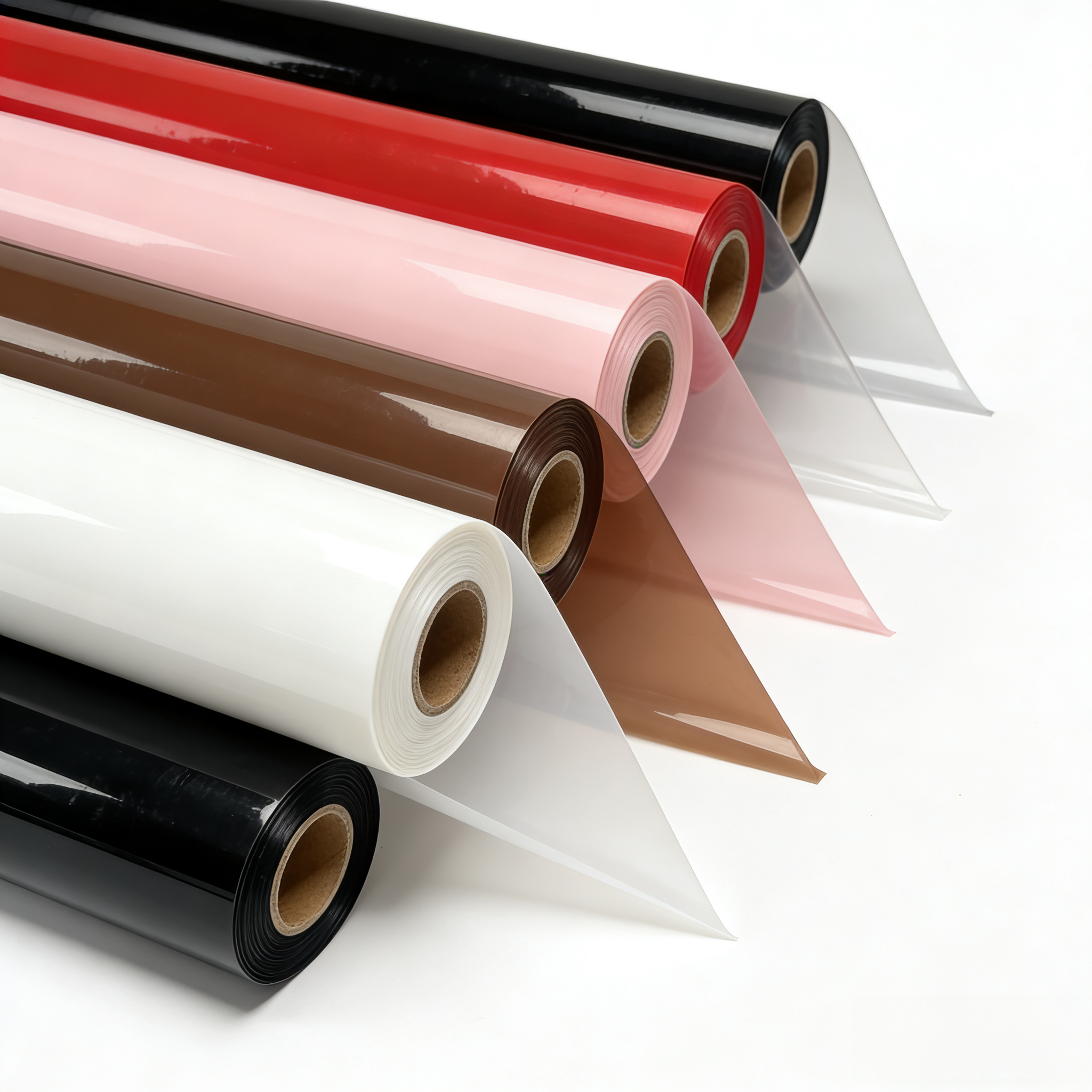

Hansa can supply you with different types of PTFE sheets or film, whether you need the PTFE sheet in roll, reinforced PTFE sheet, or cut to size, we can always supply you the quality material. Any size, any color, any type, or any thickness, Just send us your requirement and get a free sample to check the quality.

General-purpose PTFE sheets have a temperature resistance range of -180 to 260 degrees Celsius, making them suitable for most industrial applications. They have a low coefficient of friction, and their most notable characteristic is their chemical inertness, meaning they react with almost no chemical substances.

More Different Types Of PTFE Sheet You can Order From Hansa

There are various types of PTFE sheets that can be categorized in multiple ways: 1. By manufacturing process 2. By fillers/modifications 3. By color 4. By application 5. By specifications 6. Special types – including porous PTFE sheets (commonly known as “expanded PTFE boards”)

A microporous structure fabricated through a stretching process, utilized in filtration, breathable membrane applications, and biomedical fields.

Size be customized,Retail is permitted. MAX WIDTH is close to 3Meters, MAX THICKNESS can reach 10mm+

Size be customized,Retail is permitted. MAX WIDTH can reach 2Meters, MAX THICKNESS is close to 600mm.

Specialized Filler Formulations for Cold Flow Mitigation in PTFE with Blue Glass Microbeads,White Barium Sulfate,Yellow Silica.

The surface of polytetrafluoroethylene after sodium treatment is hydrophilic, which can be bonded with ordinary glue to expand its application range.

Manufactured through an extrusion molding process, suitable for thinner sheet applications with high production efficiency.

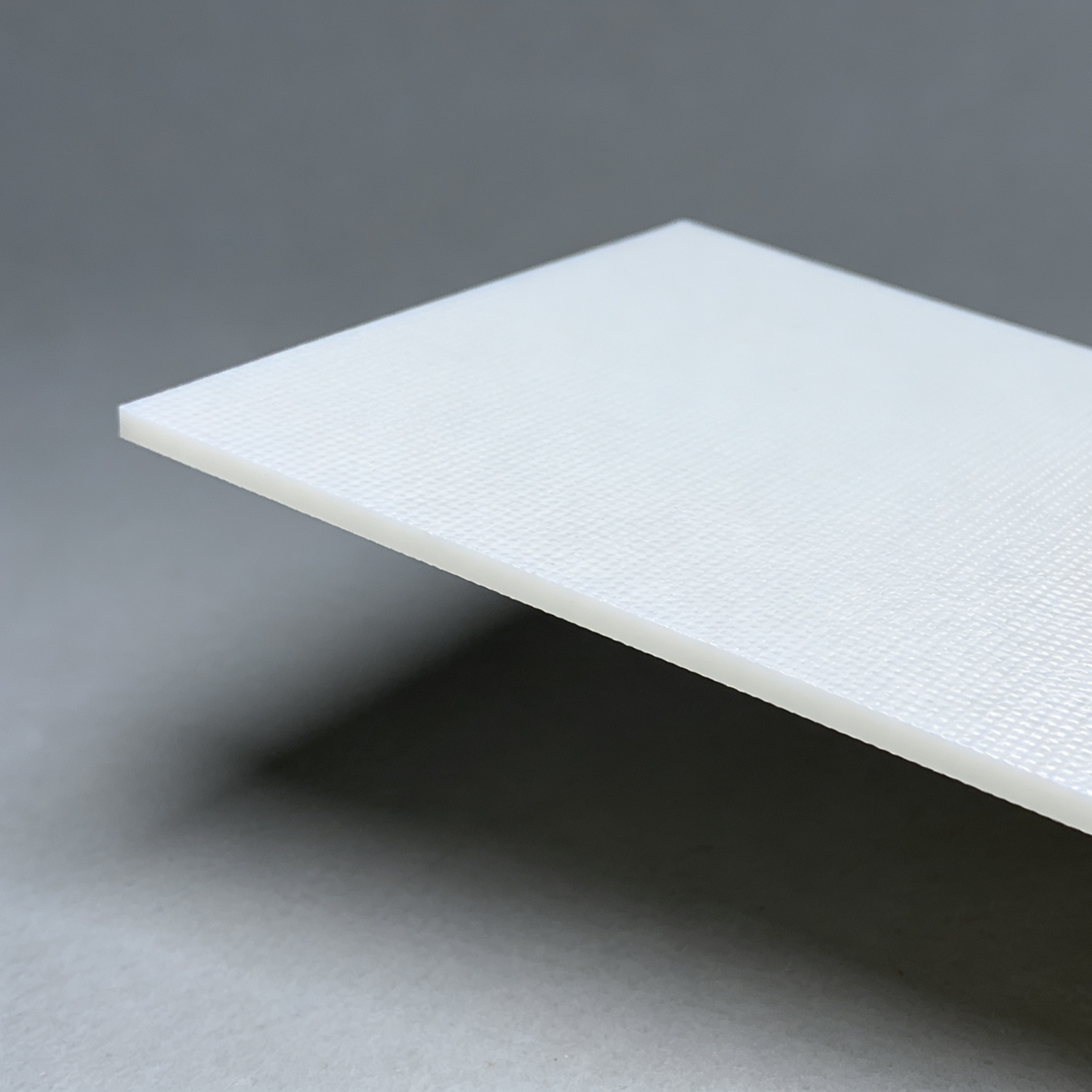

In fact, it involves bonding a fiberglass cloth to one surface of a PTFE skived sheet, giving it the ability to adhere to other surfaces and simultaneously overcoming the limitation of PTFE’s inability to be welded.

This is commonly used in the electronics industry, particularly in the flat panel display industry. Due to PTFE’s excellent high-temperature resistance and impact resistance, it effectively prevents conductive adhesive from overflowing and contaminating the substrate.

It comes in a variety of colors and serves for identification or decorative purposes. It is commonly used for wire harness classification, pipeline identification in the chemical industry, and as a decorative waterproof layer in high-end buildings.

The glass fiber content is typically 15-30%, which greatly improves the mechanical strength of the PTFE sheet, making it twice as strong as general-purpose PTFE sheets and allowing it to maintain dimensional stability under high-pressure conditions.

With a copper powder content of 20-40%, it exhibits excellent thermal conductivity, 5-10 times that of ordinary PTFE sheets, but its corrosion resistance is reduced, limiting its use to neutral corrosive media.

Typically, increasing the graphite content by 10-25% enhances the self-lubricating properties of general-purpose PTFE sheets, resulting in a very low coefficient of friction. However, it also leads to lower hardness, and the price is slightly higher than that of standard general-purpose PTFE sheets.

Key Features of PTFE Sheet

Demonstrates favorable compressive and creep resistance at ambient temperatures, though may soften under elevated temperatures, suitable for low-stress applications.

Coefficient of friction (COF) as low as 0.04, featuring a smooth surface with self-lubricating properties that eliminate the need for external lubricants.

Exhibits corrosion resistance capable of withstanding aggressive agents and the majority of chemical media (pH 0-14).

Operational range spans from -200°C to +260°C for sustained service, with short-term exposure tolerance up to 300°C.

Application Of PTFE Sheet

Industrial: Seals, gaskets, bearings, valve components, and linings for pipes and tanks.;

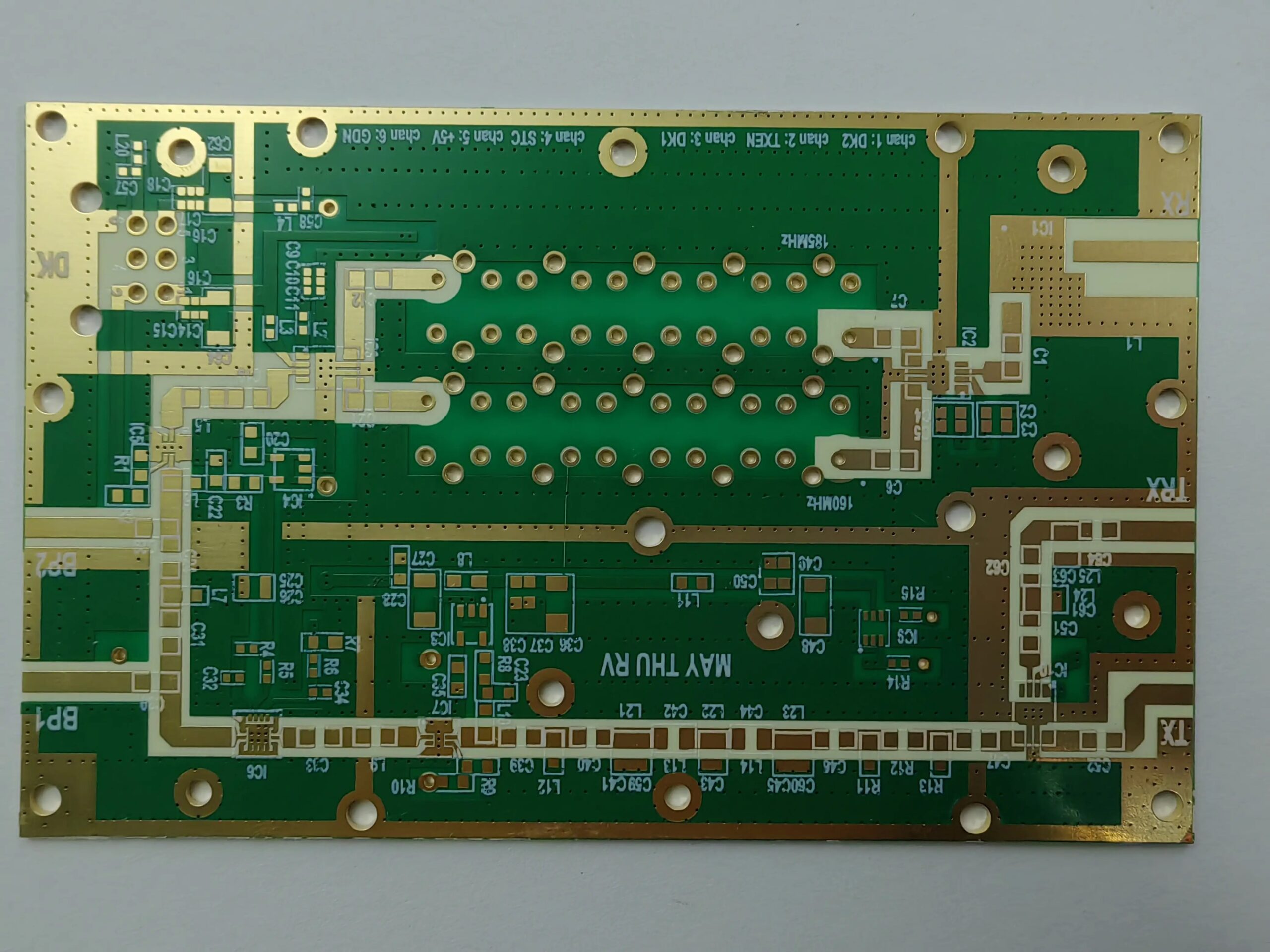

Electronics: Insulation for circuit boards, connectors, and electronic components;

Automotive: Bushings, hoses, and coatings for fuel lines;

Food & Beverage: Conveyor belts, molds, and containers;

Medical: Catheters, implantable devices, and labware.

Your Benefits

- HANSA possesses a complete product quality control system and holds certifications such as FDA, RoHS, and ISO, ensuring that our product quality meets international standards.

- HANSA offers customized services to meet your specific needs regarding the size, thickness, color, or filler materials of PTFE products, ensuring that the products fully meet your expectations. Our professional staff will stay in contact with you to answer any questions you may have.

- HANSA products offer both quality and competitive pricing, focusing on value for money. This not only saves you procurement costs but also eliminates concerns about delivery times. If you order standard products, we have ample stock and can guarantee shipment within 7 days. For customized products, we promise you will receive your order within the agreed timeframe, thanks to our stable and long-term international logistics partners.

- HANSA has 30 years of experience in the production of PTFE products and possesses mature manufacturing and processing technologies. Our sales team is professional and highly responsible, with 20 years of experience in the industry, and can provide comprehensive technical support.

Mature inventory management system

We maintain a readily available stock of standard PTFE sheets, and we have a dedicated inventory management system to facilitate the tracking and management of our stock. When you need to order specific specifications, we can accurately check the current quantity in stock and supply them promptly to meet your urgent needs.

Stable logistics partners

HANSA has established long-term partnerships with three international logistics companies: FedEx, DHL, and UPS, to meet your transportation needs to the greatest extent possible. For packaging, we use wooden crates with foam padding to protect your products and prevent damage during transit.

Company Resource

Is PTFE sheet suitable for your project? If you’re unsure, please contact us, and we will arrange for a professional to assist you. Here is our company’s catalog, which you can download and view.

Do you have doubts about product quality? Worried that the product you receive won’t be what you expected? HANSA can alleviate your concerns, as we provide professional test reports and product certificates. Click to learn more!

HANSA has professional personnel equipped for molding, turning, and CNC machining operations. This is our promotional video, which will allow you to learn about our company in the shortest possible time!

Typical Application Scenarios for PTFE Sheets

The most classic application of PTFE skived sheets is as a lining for chemical reactors, because PTFE has excellent chemical inertness and hardly reacts with any chemical substances, making it resistant to strong acids, strong bases, and other corrosive liquids. After adhesive treatment, the PTFE skived sheet adheres tightly to the reactor, and our professional technology ensures that it will not detach, extending the service life of your chemical equipment.

Due to PTFE’s extremely low coefficient of friction (only 0.04) and excellent self-lubricating properties, it is widely used in the manufacture of sliding bearings, guide rails, and piston rings, which can reduce equipment wear and save on production costs.

After processing, PTFE sheets can be used as substrates for printed circuit boards (PCBs), insulating gaskets, etc. This is because PTFE has excellent insulation properties, high temperature resistance, and very low dielectric constant and loss factor, resulting in minimal signal transmission loss.

There are specialized medical-grade PTFE materials used in high-end medical equipment, such as sterile seals or artificial heart valves. There is also food-grade PTFE, specifically labeled as harmless to humans, which can be used as a lining for household baking utensils, such as non-stick pans and oven trays.

Specifications Of Modified PTFE From Hansa

- Size description

- Virgin PTFE Properties

- Etched PTFE Properties

- Modified PTFE Sheet

| Type | Size Description |

| PTFE Molded Sheet | Regular size is Square: width x Length, from 150mm – 2000mm

Thickness: 4mm – 500mm |

| PTFE Skived Sheet | Width 300,400,500,800,1000,1200,1300,1400,1500,1600,1800,2000,2200,2500,2700mm ,Length ≥200

Thickness: 0.1-6.5mm |

| PTFE Film | Thickness: 0.02-0.5mm

Length ≥100 |

| Expanded PTFE Sheet | Width and Length: regular 1500*1500

Thickness: 0.5-10mm |

| Properties | unit | Result |

| Apparent density | g/m² | 2.10~2.30 |

| Tensile strength(min) | MPa | 15.0 |

| Elongation at break(min) | % | 150 |

| Dieletric strength(min) | KV/mm | 10 |

| Properties | Unit | Result |

| Density | g/cm³ | ≥2.18 |

| Tensile strength | MPa | ≥30 |

| Elongation at break | % | 300 |

| NO. | Filled Compound And | Tensile Strength Mpa min | Ultimate Strength % min | Compression Strength Mpa |

| Content By Wt | min | |||

| 1 | 20% Glass Fiber | 10 | 120 | 16 |

| 2 | 25% Glass Fiber | 10 | 100 | 16 |

| 3 | 20%Glass Fiber 5%Graphite | 10 | 120 | 16 |

| 4 | 60%Bronze | 10 | 80 | 20 |

| 5 | 15%Carbon Fiber | 11 | 130 | 16 |

| 6 | 24%Bronze 12%Glass Fiber | 9 | 100 | 16 |

| 6%Carbon | ||||

| 7 | 15%Glass Fiber 10% Poly – | 10 | 120 | 16.7 |

| imide5%Graphite |

Teflon and PTFE are essentially the same thing, both referring to the material polytetrafluoroethylene. The difference is that Teflon is a registered trademark, originally owned by DuPont, and now owned by Chemours, an independent company spun off from DuPont.

- Difficult to Process, High Cost: Due to PTFE’s unique properties, it has an extremely high melting point and requires special processing techniques, like “cold pressing,” which is time-consuming and requires specialized equipment. This makes PTFE expensive and challenging to process.

- Poor Creep Resistance: Compared to materials like nylon and PEEK, PTFE has lower hardness and rigidity. In practical applications, if PTFE is continuously under pressure, it may permanently deform over time.

- Decomposes and Releases Toxins at High Temperatures: When PTFE is exposed to temperatures above 260°C for long periods, it begins to break down and release toxic substances. At temperatures exceeding 350°C, the decomposition process accelerates, releasing harmful fumes.

- Non-Biodegradable: PTFE’s high thermal stability prevents it from naturally degrading. Recycling PTFE requires high temperatures, which can release toxic by-products, leading to environmental pollution and potential harm to human health.

The lifespan of PTFE depends on its application environment. Under clean conditions and normal operating temperatures, PTFE can last for 10-50 years. However, if it operates under high pressure for extended periods, its lifespan will be significantly shorter, possibly only 7-8 years, or even 4-6 years. Of course, this also depends on the grade of the PTFE material.

Currently, there are two methods for recycling PTFE:

- Mechanical Recycling: PTFE is ground into fine powder, compacted, and then sintered at a high temperature of 370°C.

- Chemical Recycling (also known as Pyrolysis): When exposed to temperatures over 400°C, PTFE decomposes into tetrafluoroethylene monomers.

After receiving the goods, you can quickly perform an acceptance inspection. First, check if the PTFE sheet is milky white and free of color variations. Secondly, measure its volume and weight to calculate the density of the PTFE sheet. If the density is within 2.1-2.2 g/cm³, it is considered acceptable. If you have sufficient time, you can immerse it in concentrated sulfuric acid solvent, observe it for 24 hours, then remove and weigh it. Compare the weight to the weight upon receipt; if the change rate is no more than 1%, and there are no cracks on the surface, it is considered acceptable.

PTFE, commonly known as “the king of plastics,” boasts excellent overall performance and is suitable for most applications. It also has a long service life, lasting 10-50 years or more. We can develop customized solutions for your specific project, providing personalized professional service to address your concerns.

Yes, PTFE is available in different grades, including general-purpose, food-grade, and medical-grade. Each grade is suitable for different applications. Furthermore, the raw materials for PTFE also vary, with different brands available from manufacturers such as DuPont and Daikin. In addition, there is both pure PTFE and recycled PTFE.

If you’re simply cutting PTFE sheets, you can do it yourself. For thin sheets, you can score the surface with a utility knife and then easily break it apart by hand; for thicker sheets, you’ll need a saw. First, secure the sheet, then mark the cutting line, and finally, saw along the marked line. However, if your project is large and involves a significant amount of PTFE sheets, you’ll need to use a CNC machine for cutting. This will greatly improve efficiency, but it may increase your costs.

Related Products

PTFE Sheets

Polytetrafluoroethylene sheets are mostly called PTFE sheets. Or, you may also call them Teflon sheets. Of course, the two names refer to the same product except that “Teflon” is PTFE made by DuPont.

Generally speaking, these sheets are made from fluorine and carbon bonds. That is where it derives the name Polytetrafluoroethylene.

Due to the strong carbon bonds, they are considered high molecular sheets. A reason they are common in many applications today.

Types of PTFE Sheets Available

You can use broad criteria to classify Teflon sheets. It is due to the wide customization options.

Ideally, you may want:

- PTFE sheets with adhesive – they have adhesive substrate on one surface

- Cut to size PTFE sheets – the PTFE are cut according to your specific requirements

- Sheets with varying thickness – you may choose the PTFE sheet 3mm thick or 100 mm thick

In short, the available options depend on unique customization options. More importantly, this will also determine the PTFE sheet price.

General Purpose PTFE Sheet Material

Of course, the customization makes the Teflon sheets suitable for very specific applications. However, you may choose general-purpose PTFE sheets.

| Property of PTFE Sheet Material | Rating |

| Tensile strength | Poor |

| UV resistant | Good |

| Hardness | Medium soft |

| Impact strength | Good |

| Dimensions | Varies but it can be 6 by 6 inches to 48 by 48 inches |

Glass Filled PTFE Sheets

If you are looking for sheets with improved mechanical strength, impact, and abrasion resistance, then go for those with glass fiber. In most cases, these sheets have about 25% glass fibers

Features of Polytetrafluoroethylene Sheets

There are many reasons to choose these sheets:

- High melting makes the resin perfect for most continued service

- At high temperatures, PTFE material will remain stable. The temperature range is -200°C to +260°C.

- Known for superior anti-stick properties

- Superior insulation properties

- Co-efficient of friction is relatively low

- Better corrosion resistance than standard plastic material

- They are hydrophobic – they tend to repel water

- Chemically inert

- Are FDA approved

- Sensitive to gamma radiation

At times, your virgin PTFE sheet will not offer all these features. A reason you must reinforce the PTFE material. These sheets are made from 100% pure Polytetrafluoroethylene resin.

Let’s compare two interesting sheets:

| Virgin PTFE Sheet | Mechanical PTFE Sheet |

| · Made from 100% pure Polytetrafluoroethylene resin

· High physical properties · Normal application · No additional additives |

· Made from reprocessed Polytetrafluoroethylene resin

· Low physical properties · High-performance applications · Filled with additives to improve the properties |

Forms in Which you can Ship PTFE Sheets

You can get these materials as either flat or rolled. The packaging methods depend on the sheet thickness.

In most cases, the PTFE sheet rolls have a thickness of less than 0.093″. Otherwise, rolling Polytetrafluoroethylene sheets with higher thicknesses is not recommended.

Uses

You can machine or fabricate the PTFE material sheet to make many parts such as:

- PTFE gaskets

- PTFE bushing

- PTFE lining

- PTFE sliding plate

- PTFE electrical insulation parts

- PTFE washers